Caution – State GPG 81 370NEA User Manual

Page 20

20

This water heater is provided with a properly rated/sized and

certified combination temperature - pressure (T&P) relief valve

by the manufacturer. See Temperature-Pressure relief Valve

on pages 14-15 for information on replacement and other

requirements.

Water Damage Hazard

Temperature-Pressure Relief Valve discharge

pipe must terminate at adequate drain.

•

CAUTION

Install a discharge pipe between the T&P valve discharge

opening and a suitable floor drain. Do not connect discharge

piping directly to the drain unless a 6” (15.2 cm) air gap is

provided. To prevent bodily injury, hazard to life, or property

damage, the relief valve must be allowed to discharge water

in adequate quantities should circumstances demand. If the

discharge pipe is not connected to a drain or other suitable

means, the water flow may cause property damage.

t&p ValVe discharge pipe reQuirements:

• Shall not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both

Temperature-Pressure relief Valve and the discharge pipe.

• must terminate a maximum of six inches above a floor

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at an

adequate drain inside the building.

• Shall not have any valve or other obstruction between the

relief valve and the drain.

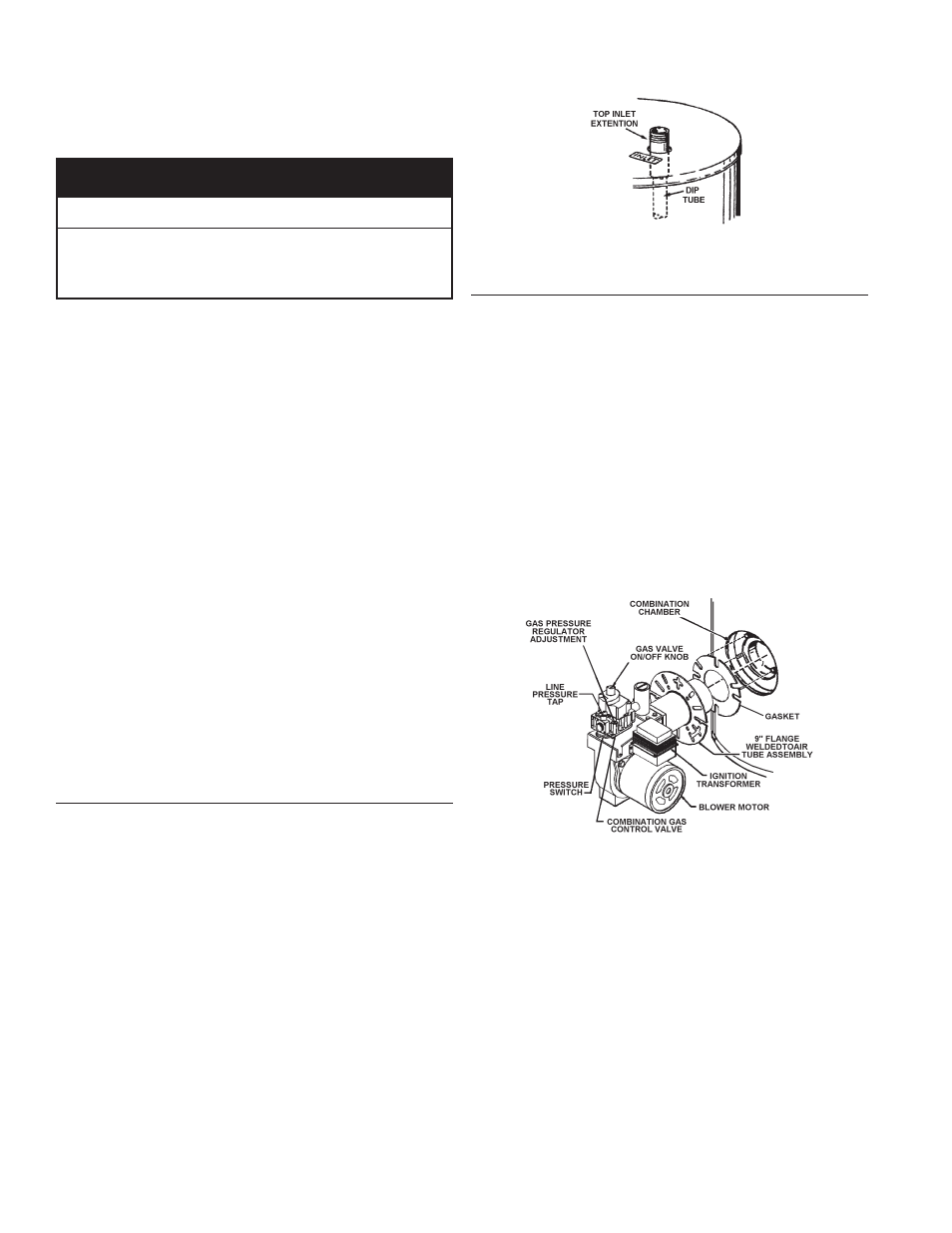

installation diagrams - top inlet/outlet usage

use of the top inlet water connection requires an inlet dip tube

(refer to Figure 17). The tube is supplied in the heater. Follow

caution labels if applying heat to this fitting. Do not allow pipe

dope to contact the plastic tube during installation.

tube inlet installation

figure 17.

burner installation

remove the factory-installed insulation covering the combustion

chamber opening. (A utility knife is useful for cutting out the

insulation). Cut the insulation back even with the jacket opening.

Install the flange gasket (which is usually taped to the heater jacket)

over the three bolts protruding from the tank at the combustion

chamber opening.

remove hardware (3 hex nuts, 3 flat washers, and 3 lock washers)

from the shipping bag attached to the heater’s electrical conduit.

Begin assembling the power burner to the tank by placing the power

burner nozzle in the combustion chamber opening. Slide the nozzle

into the tank and rotate the mounting flange to engage the mounting

bolts, refer to Figure 18. Then, place the flat washers followed by

the lock washers, and finally the hex nuts on the mounting bolts.

Hand tighten the nuts. Then gradually tighten each nut alternating

between the 3 mounting bolts. Do not over tighten as damage to

the flange gasket or to the tank may result. refer to Figure 18.

power burner installation

figure 18.