Venting installation – State GPG 81 370NEA User Manual

Page 16

16

direct Vent appliances

Appliances installed in a Direct Vent configuration that derive all

air for combustion from the outdoor atmosphere through sealed

intake air piping are not factored in the total appliance input Btu/

hr calculations used to determine the size of openings providing

fresh air into confined spaces.

eXhaust fans

Where exhaust fans are installed, additional air shall be provided

to replace the exhausted air. When an exhaust fan is installed

in the same space with a water heater, sufficient openings to

provide fresh air must be provided that accommodate the

requirements for all appliances in the room and the exhaust fan.

undersized openings will cause air to be drawn into the room

through the water heater’s vent system causing poor combustion.

Sooting, serious damage to the water heater and the risk of fire

or explosion may result. It can also create a risk of asphyxiation.

louVers and grilles

The free areas of the fresh air openings in the instructions that

follow do not take in to account the presence of louvers, grilles or

screens in the openings.

The required size of openings for combustion, ventilation and

dilution air shall be based on the “net free area” of each opening.

Where the free area through a design of louver or grille or screen

is known, it shall be used in calculating the size of opening

required to provide the free area specified. Where the louver and

grille design and free area are not known, it shall be assumed

that wood louvers will have 25% free area and metal louvers and

grilles will have 75% free area. Non motorized louvers and grilles

shall be fixed in the open position.

unconfined space

An unconfined Space is one whose volume IS NOT leSS THAN

50 cubic feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the

total input rating of all appliances installed in the space. rooms

communicating directly with the space, in which the appliances

are installed, through openings not furnished with doors, are

considered a part of the unconfined space.

makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and fireplaces shall

also be considered in determining the adequacy of a space to

provide combustion, ventilation and dilution air.

unusually tight construction

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of unusually tight construction (for

example, weather stripping, heavily insulated, caulked, vapor

barrier, etc.) additional air must be provided using the methods

described in the Confined Space section that follows.

confined space

A Confined Space is one whose volume is less than 50 cubic

feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the total input

rating of all appliances installed in the space.

Openings must be installed to provide fresh air for combustion,

ventilation and dilution in confined spaces. The required size for

the openings is dependent on the method used to provide fresh

air to the confined space and the total Btu/hr input rating of all

appliances installed in the space.

Venting installation

Venting

THe INSTruCTIONS IN THIS SeCTION ON VeNTING muST

Be FOllOWeD TO AVOID CHOkeD COmBuSTION Or

reCIrCulATION OF Flue GASeS. SuCH CONDITIONS

CAuSe SOOTING Or rISkS OF FIre AND ASPHyXIATION.

Heater must be protected from freezing downdrafts.

remove all soot or other obstructions from the chimney that will

retard a free draft.

Type B venting is recommended with these heaters.

This water heater must be vented in compliance with all local

codes, the current revision of the National Fuel Gas Code

(ANSI-Z223.1) and with the Category I Venting Tables.

If any part of the vent system is exposed to ambient temperatures

below 40°F (4.4°C) it must be insulated to prevent condensation.

• Do not connect the heater to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by

many local building codes as is the practice of venting gas

fired equipment to the duct work of ventilation systems.

• Where a separate vent connection is not available and the vent

pipe from the heater must be connected to a common vent with

an oil burning furnace, the vent pipe should enter the smaller

common vent or chimney at a point above the large vent pipe.

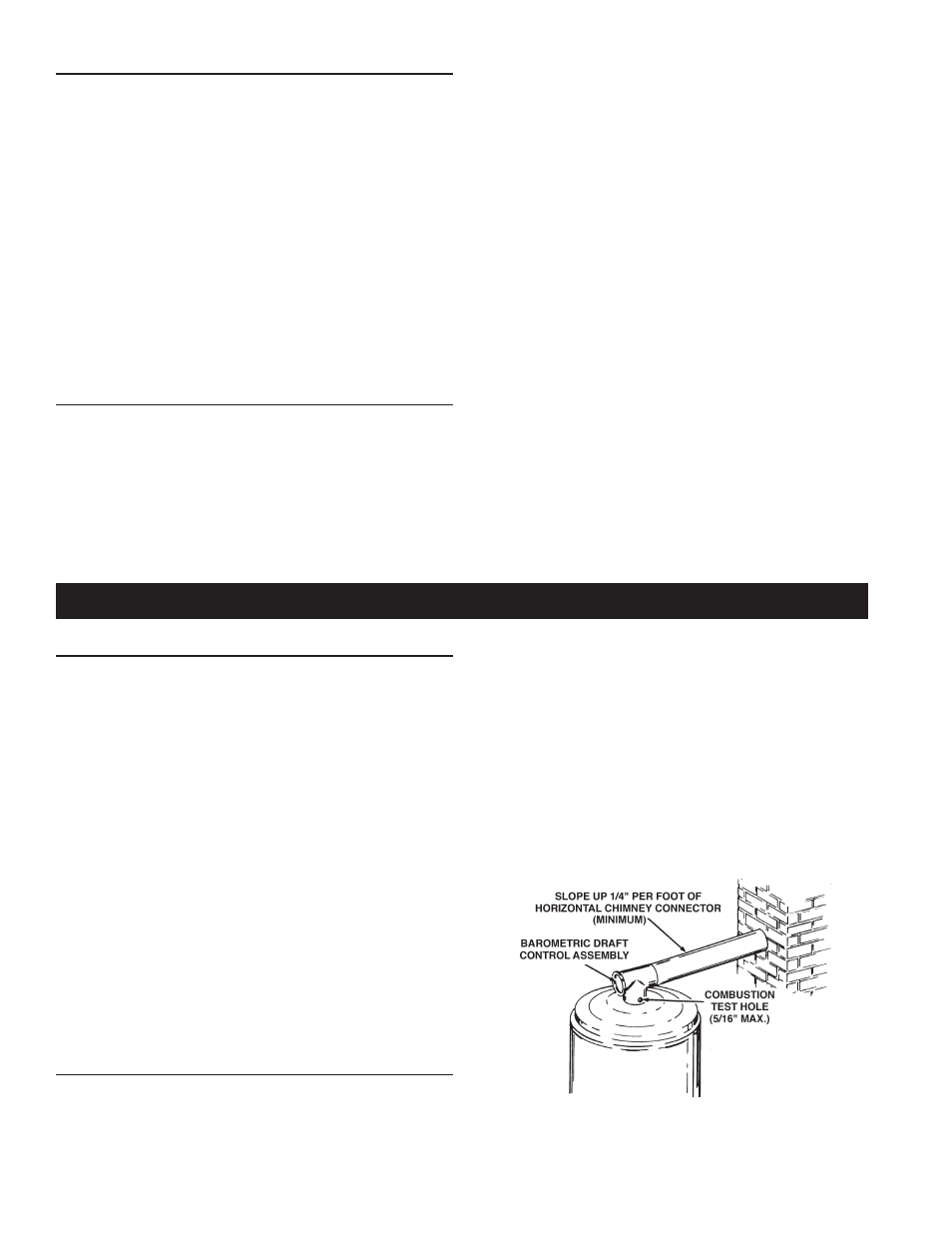

barometric draft control assembly

A double-acting barometric draft control assembly is provided

with each unit. The draft control assembly must be installed

without alteration. This assembly is factory adjusted for horizontal

application only and must be attached to the heater as shown in

Figure 11. The outlet of the draft control assembly may be rotated

to face in direction needed. The assembly must be fitted to the

jacket cover such that it is plumb and level to the ground. Fasten

the draft control assembly to the top cover using sheet metal

screws at three locations, or more, as required.

Dampers or other obstructions must not be installed between the

heater and the barometric draft control assembly.

Do not adjust settings on gate. Counterweight washers are factory

adjusted and should result in breeching pressure measurements

at the combustion test hole (Figure 11) within the range shown

in Table 9.

note: A negative draft must be maintained in the vent piping.

When installed, the damper gate must pivot freely in the ring

guides. This gate will automatically adjust to regulate the chimney

draft imposed on the heater.

proper draft controller and

Vent pipe installation

figure 11.