Warning – State GS6 75 YRVHTL User Manual

Page 35

4” VENT

PIPE

3” RUBBER

COUPLING

(SUPPLIED)

3” VENT PIPE,

3 in. MAX

LENGTH

3”-4”

ADAPTER

(FIELD

SUPPLIED)

BLOWER

CONFIGURATION

FOR HI-INPUT

HEATER

CONNECTED TO

4” VENTING.

Figure 41.

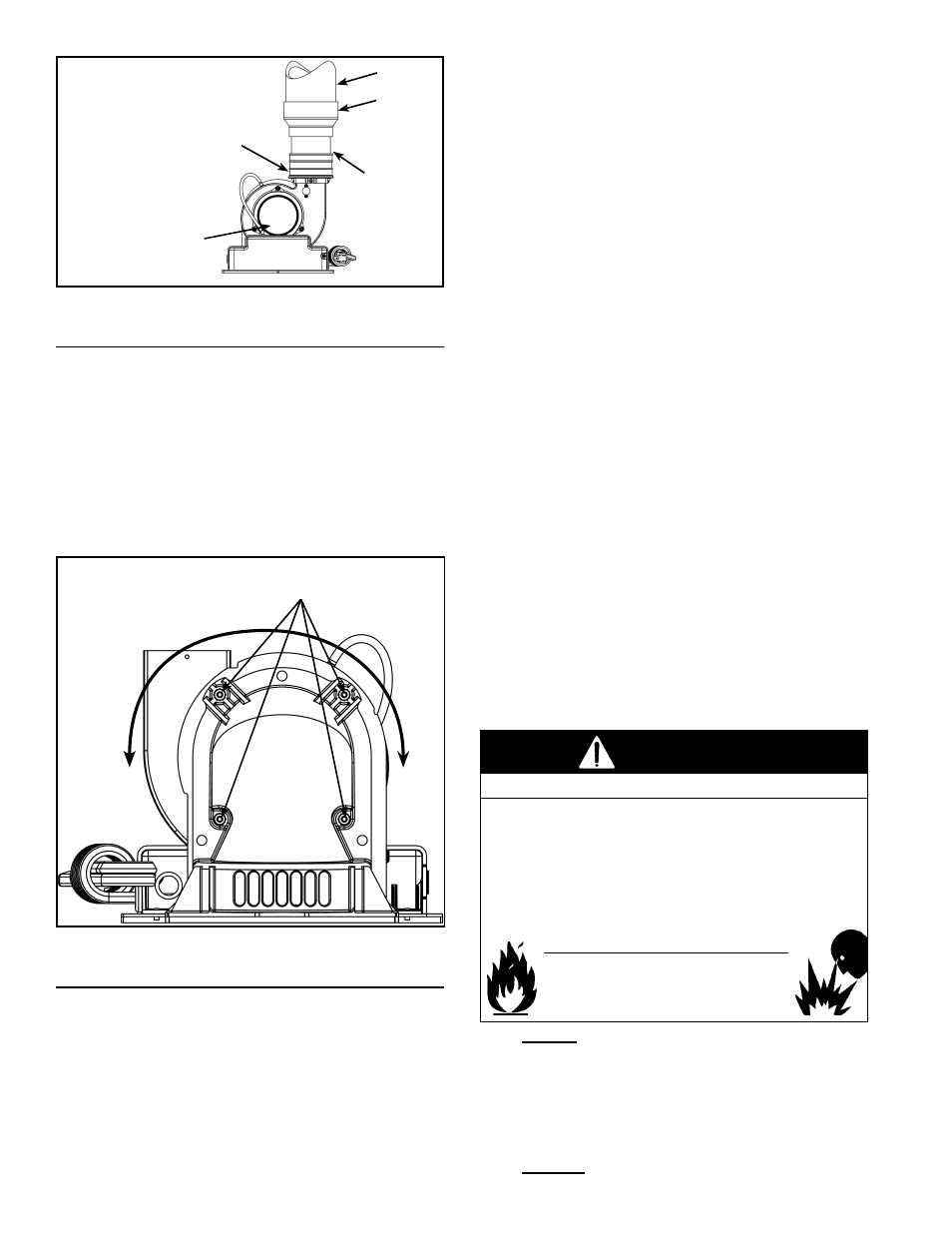

BLOWER EXHAUST DIRECTION

The blower assembly may be rotated 90 degree clockwise

or counterclockwise to allow horizontal venting in areas

having restricted space above the water heater. To rotate

the blower outlet, remove the four nuts (with 11/32” nut

driver) (see Figure 42), securing the fl ue collector to the

blower housing. Pull the blower assembly forward to free

it from the mounting studs. Rotate the blower housing

clockwise or counter-clockwise and align the four holes

and screws together. Reattach the blower housing to the

fl ue collector.

11/32” nut

Note: Coupling to vent system

not shown for clarity.

Figure 42.

VENT PIPE PREPARATION

1. INITIAL PREPARATION

• Make sure the solvent cement you are planning to

use is designed for the specifi c application you are

attempting.

•

Know the physical and chemical characteristics and

limitations of the PVC and CPVC piping materials

that you are about to use.

•

Know the reputation of your manufacturer and their

products.

•

Know your own qualifications or those of your

contractor. The solvent welding technique of joining

PVC and CPVC pipe is a specialized skill just as any

other pipe fi tting technique.

•

Closely supervise the installation and inspect the

fi nished job before start-up.

•

Contact the manufacturer, supplier, or competent

consulting agency if you have any questions about

the application or installation of PVC and CPVC

pipe.

•

Take the time and effort to do a professional job.

Shortcuts will only cause you problems and delays

in start-up. By far, the majority of failures in PVC and

CPVC systems are the result of shortcuts and/or

improper joining techniques.

2. SELECTION OF MATERIALS (PCV and CPVC

VENTING)

•

Cutting Device - Saw or Pipe Cutter

•

Deburring Tool, Knife, File, or Beveling Machine (2”

and above)

•

Brush - Pure Bristle

•

Rag - Cotton (Not Synthetic)

•

Primer and Cleaner

•

Solvent Cement - PVC for PVC Components and

CPVC for CPVC Components only

•

Containers - Metal or Glass to hold Primer and

Cement. Select the type of PVC or CPVC materials

to be used on the basis of their application with

respect to chemical resistance, pressure rating,

temperature characteristics, etc.

•

Insertion Tool - Helpful for larger diameter pipe and

fi ttings 6” and above.

Read instruction manual before

installing, using or servicing

water heater.

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

• Avoid all ignition sources if you smell gas.

• Do not expose water heater control to excessive gas

pressure.

• Use only gas shown on rating plate.

• Maintain required clearances to combustibles.

• Keep ignition sources away from faucets after extended

period of non-use.

Fire or Explosion Hazard

WARNING

Primer:

It is recommended that Tetrahydrofuran (THF) be

used to prepare the surfaces of pipe and fi ttings for

solvent welding. Do not use water, rags, gasoline

or any other substitutes for cleaning PVC or CPVC

surfaces. A chemical cleaner such as MEK may be

used.

Cement:

www.statewaterheaters.com

35