Caution – State GS6 75 YRVHTL User Manual

Page 34

TERMINATION

MAY BE 90°

ELBOW

3” MIN.

LENGTH

ROOF

LINE

A VENT USED IN A

SPECIAL VENTING

SYSTEM WITH POSITIVE

VENT PRESSURE AND

PASSING THROUGH A

ROOF SHALL EXTEND AT

LEAST 18” ABOVE THE

HIGHEST POINT WHERE

IT PASSES THROUGH THE

ROOF SURFACE AND ANY

OTHER OBSTRUCTION

WITHIN A HORIZONTAL

DISTANCE OF 18”. A

VERTICAL VENTING

SYSTEM MUST BE

SUPPORTED EVERY 5 ft..

18” OR

ABOVE

ANTICIPATED

SNOW LEVEL

RODENT

SCREEN

(INSTALL

INTO

ELBOW)

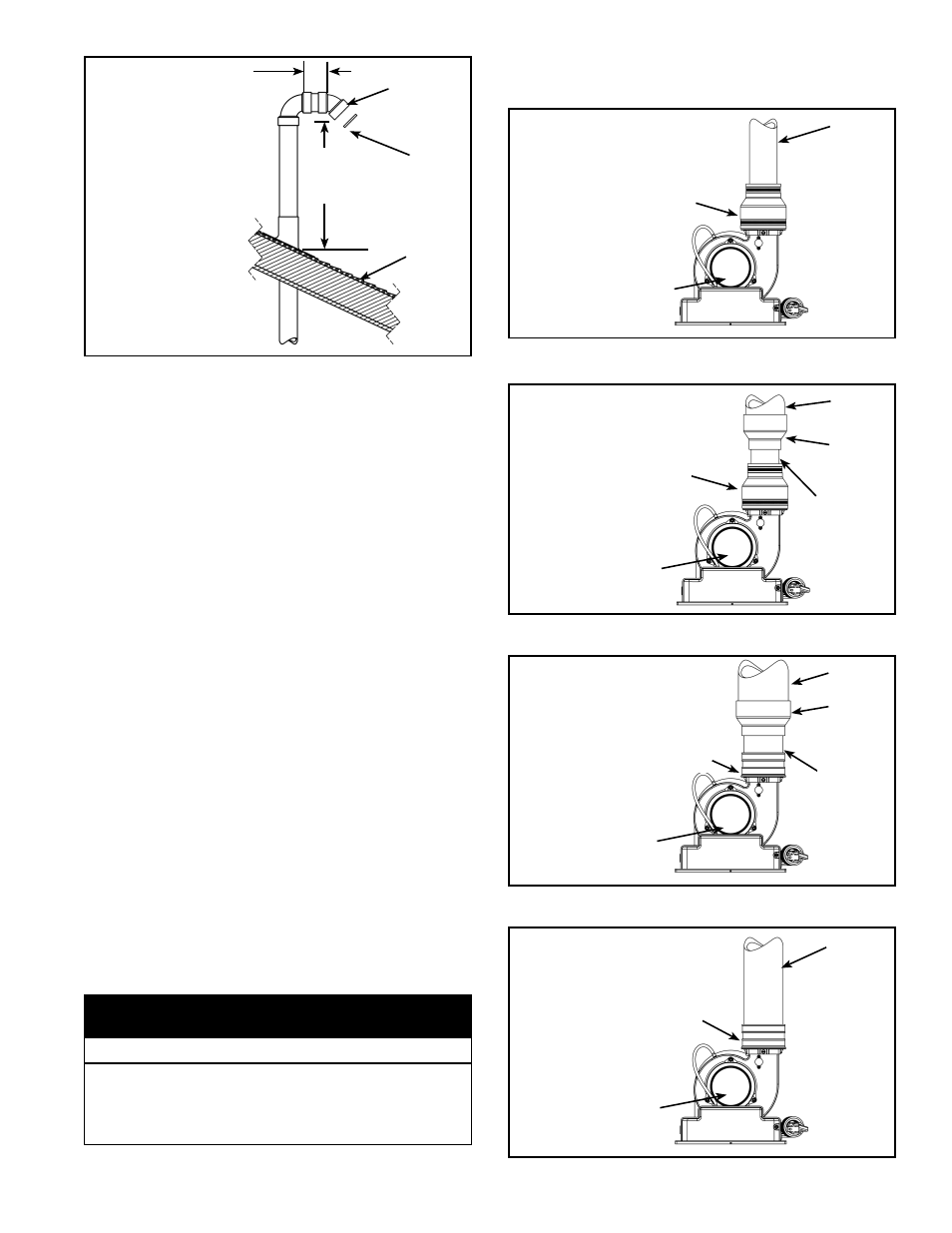

Figure 36.

Vent pipe connection to blower

1. The plastic vent piping connects into the rubber

coupling located on the top of the blower assembly.

This coupling includes gear clamps to connect the

venting to the blower. These connections must be

properly seated and tightened to prevent the leakage

of fl ue gases into the area. See Figure 37 thru Figure

41.

2. The 40, 50 and 60-gallon heaters with rated inputs of

50k Btu/hr or less are designed and supplied with a

2” rubber coupling to accept the vent pipe.

3. The 50 and 75-gallon models with rated inputs of 60k

Btu/hr or more are supplied with a 3” rubber coupling

to accept the vent pipe. Note: Polypropylene vent

systems require separate adaptor.

4. Before installing clean and lightly sand the end of the

PVC/CPVC plastic vent piping that will connect into

the rubber coupling. For polypropylene vent systems

follow manufacturer’s instructions.

5. Loosen the upper clamp on the rubber coupling and

insert the sanded end of the vent piping a full 1-1/4”.

Do not use glue or sealant in the rubber coupling.

Check that there is no stress on the connection or the

vent piping that may be caused by twisting or bending.

6. Tighten the upper clamp so that the vent piping is

fi rmly secured in the coupling and is gas tight. Do not

over tighten or cause distortion of any of the parts.

Ensure the bottom of the rubber coupling is fi rmly

seated on the blower outlet and that the lower gear

clamp is also secure. Check to ensure there is no

distortion or movement of the clamped assembly once

it is completed.

• Do not overtighten the top and bottom gear clamps of the

rubber coupling.

• Do not apply solvent cement or silicone to the rubber

coupling connection.

Property Damage Hazard

CAUTION

Different coupling installations according to vent

sizes

BLOWER

2” VENT

PIPE

2” RUBBER

COUPLING

(SUPPLIED)

CONFIGURATION

FOR 40, 50 AND

60-GALLON (LO-

INPUT) HEATERS

CONNECTED TO

2" VENTING.

Figure 37.

2” RUBBER

COUPLING

(SUPPLIED)

BLOWER

3” VENT

PIPE

2”-3”

ADAPTER*

(FIELD

SUPPLIED)

2” VENT PIPE,

75mm (3 in.)

MAX LENGTH

CONFIGURATION

FOR 40, 50 AND

60-GALLON (LO-

INPUT) HEATERS

CONNECTED TO

3” VENTING.

* FOR 3” DIRECT

CONNECTION TO

THE BLOWER,

ORDER

COUPLING Kit #

9008311005

(SEE ALSO Figure

41).

Figure 38.

4” VENT

PIPE

3” RUBBER

COUPLING

(ORDER COUPLING

Kit # 9008311005

TO REPLACE 2”

RUBBER COUPLING

SUPPLIED.)

3” VENT PIPE,

3 in. MAX

LENGTH

3”-4”

ADAPTER

(FIELD

SUPPLIED)

BLOWER

CONFIGURATION

FOR LO-INPUT

HEATERS

CONNECTED TO

4” VENTING.

LOW-INPUT

HEATERS ARE

SUPPLIED WITH

A 2” RUBBER

COUPLING.

Figure 39.

3” VENT

PIPE

3” RUBBER

COUPLING

(SUPPLIED)

BLOWER

CONFIGURATION

FOR HI-INPUT

HEATERS

CONNECTED TO

3” VENTING.

(OPTIONAL

CONFIGURATION

FOR LO-INPUT

HEATERS

CONNECTED TO

3” VENTING.)

Figure 40.

34 www.statewaterheaters.com