Actron CP7001 User Manual

Page 2

2

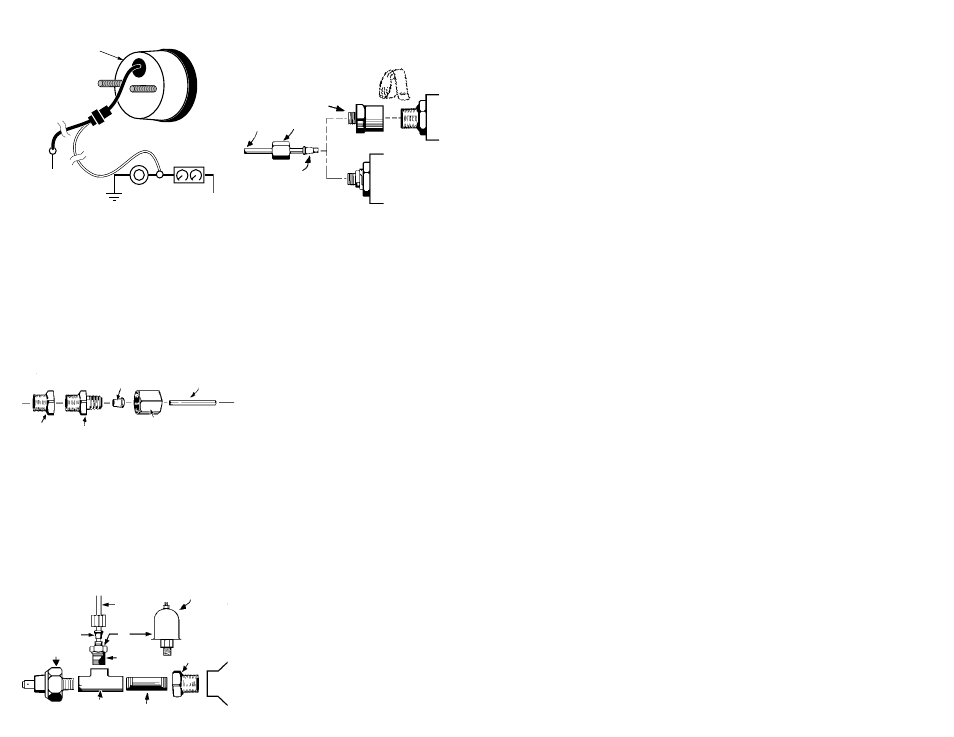

5. If the hex nut adapter is not attached to the

gauge, then wrap Teflon tape around the adapt-

er’s threads and attach the hex nut adapter.

Refer to Figure 5.

For Mechanical Gauges:

1. If you are monitoring a fluid system, drain the

fluid level to a level below the warning light

sender location.

2. Remove the warning light sender from the

engine and install the engine fitting in the same

location. If an adapter is required, first install the

adapter and then install the engine fitting.

3. uncoil a few feet of tubing and slide the hex nut

and ferrule over the end of the tubing as shown

in Figure 3. Insert the tubing into the engine

fitting, and then tighten the hex nut into the

engine fitting.

Figure 5

heX nuT ADAPTeR

heX nuT

TuBIng

FeRRule

1/8” nPT

gAuge

CoMPRessIon

FITTIng gAuge

TeFlon TAPe

Figure 4

To MeChAnICAl gAuge

eleCTRICAl gAuge

senDeR

hose

FeRRule

WARnIng lIghT

senDeR

T-FITTIng

nIPPle

engIne

BloCk

ADAPTeR

engIne

FITTIng

oR

4.

Optional T-Fitting (CP7556) (Figure 4) - Install

the nipple into the T-Fitting and tighten the

end of the other nipple into the warning light

sender location. Install an adapter fitting

first if needed. In one of the two remaining

openings in the T-Fitting, insert the engine fitting

and then follow step 3 to connect the pressure

tubing. Insert the warning light sender into the

remaining T-Fitting opening. Install an adapter

fitting first, if needed (we do not produce metric

fittings for the connection from a metric warning

light sender to the T-Fitting).

Figure 2b

For Negative Dimmer Controls

To

gRounD

DIMMeR

ConTRol

DAsh

lIghTIng

WhITe

Blue

+12V

+12V

gAuge

Figure 3

FeRRule

TuBIng

ADAPTeR

engIne FITTIng

heX nuT

6. Route the remaining tubing through the fire

wall to the gauge mounting location. leave at

least one 3” or longer loop in the tubing before

it enters the fire wall and protect the tubing from

rough edges of the fire wall hole.

7. Repeat step 3 to attach the tubing to the

gauge.

8. Complete the mounting of the gauge.

9. Refill the fluid level, if drained, to its normal

level.

10. Start the engine and observe the fitting con-

nections for leaks and the gauge for proper

operation.

For Electrical Gauges:

1. If you are monitoring a fluid system, drain the

fluid level to a level below the warning light

sender location.

2. Remove the warning light sender from the

engine and insulate the end of the sender wire if

a T-Fitting is not being used. Install the gauge’s

sender in the same location in the engine block.

If an adapter is required, first install the adapter

and then the gauge’s sender.

3.

Optional T-Fitting (CP7556) (Figure 4) -

Install the nipple into the T-Fitting and tighten

the other end of the nipple into the warning light

sender location in the engine block. Install an

adapter fitting first if needed. In one of the two

remaining openings in the T-Fitting, insert the

gauge sender. Insert the warning light into the

remaining T-Fitting opening. Install the adapter

fitting first, if needed. (we do not produce metric

fittings for the connection from a metric warning

light sender to the T-Fitting).

4. Run a length of 18-gauge insulated copper wire

from the gauge’s sender to the gauge’s mount-

ing location.

5. Connect the wire to the connection on top of the

gauge sender.

6. Connect the sender wire to the ”s” connec-

tion post as shown in Figure 6. Do not over

tighten.