Swaybar setup – BMR Suspension XSB005 User Manual

Page 2

ANTI-ROLL BAR INSTALLATION

Part # XSB005 (Continued)

axle articulates.). Once they have been tack welded, unbolt the tabs

and swing the sway bar down out of the way to gain weld access.

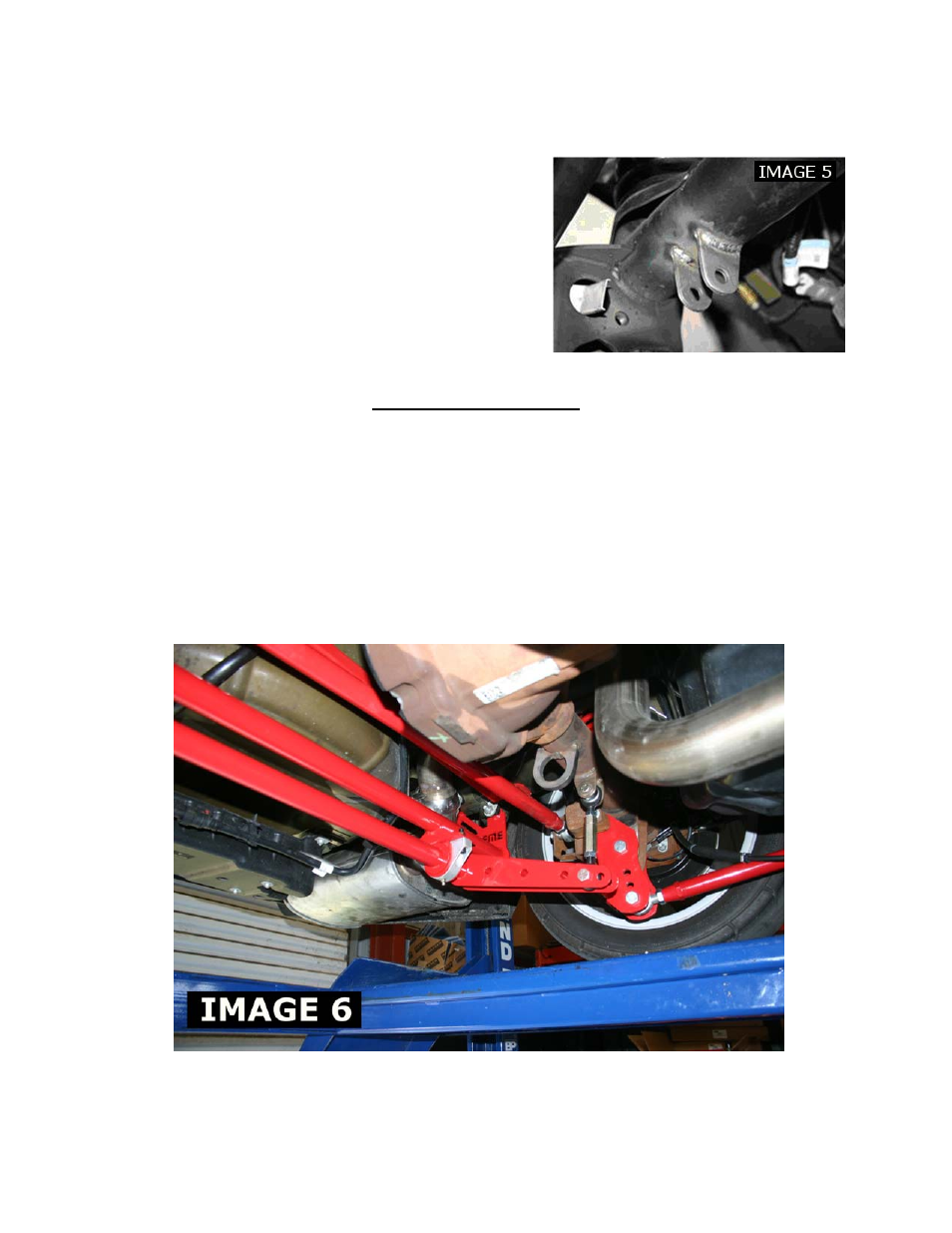

Weld tabs into place. Finished tabs should look similar to Image 6

below.

11. Re-install the end links. End-links should be made as short as

possible while still providing adjustment. Insert the supplied ½” x

2-3/4” bolts and tighten using a ¾” wrench and ¾” socket.

Tighten the jam-nuts on the end-links using two ¾” wrenches.

12. Double check all bolts to verify they are tight. Grease the

polyurethane bushings with a silicone based polyurethane lube.

13. Re-install both wheels and tires.

SWAYBAR SETUP

Because every vehicle is different there isn’t one ideal setup that will work for every application. Weight bias, tire

choice, driving style and horsepower will dictate which setting works best for you but as a general rule of thumb you

may follow the proceeding guidelines:

•

Furthest hole from bar:

This is the lightest setting and the recommended starting point for

most applications.

•

Closest hole to bar:

Use this setting if the car still wants to torque steer or will not leave

the line without excessive body roll.

It is also possible to fine tune your sway bar by pre-loading the end links. BMR recommends starting with a neutral

setup. This means that both sides are adjusted equally and no pre-load is in the bar. If the car tries to steer right on

launch, either lengthen the passenger side end link or shorten the drivers’ side end link to compensate. If it tries to steer

left at launch, shorten the passengers’ side end link or lengthen the drivers’ side to compensate.

WWW.BMRSUSPENSION.COM

This product is an aftermarket accessory and not designed by the vehicles manufacturer for use on this vehicle. As

such, Buyer assumes all risk of any damage caused to the vehicle or person during installation or use of this product.