Www.bmrfabrication.com, Upper a-arms with tall spindle – aa018 – BMR Suspension AA030 User Manual

Page 3

BMR A-ARM INSTALLATION INSTRUCTIONS FOR GENERAL MOTORS TYPE SUSPENSIONS

UPPER A-ARMS with TALL SPINDLE – AA018

These instructions only apply to those cars that are being converted to larger disc brakes and taller spindles. Part Number AA018 will not work with OE spindles.

1. Lift the vehicle to an appropriate work height and support with jack stands. Remove both front wheels/tires.

2. Remove shocks.

3. Start on one side of the vehicle. Remove the cotter pin and castle nut on the outer tie rod end and separate the tie rod

from the spindle. Remove the brake line from the caliper and secure.

4. Turn the spindle in one direction to gain access to the castle nuts of both ball joints. Remove the cotter pins and loosen

the castle nuts but DO NOT remove them. Using a brass hammer, hit the spindle around the ball joint mounting hole

until the ball joint pops loose. A pickle fork may also be used for loosening the ball joint.

5. Position a floor jack under the A-arm and lift the A-arm until there is no spring tension on the ball joints. Remove both

castle nuts. Pivot the upper A-arm upward until the spindle/rotor/caliper assembly can be lifted up off the lower ball

joint and removed.

6. Remove the two nuts that attach the upper A-arm to the frame and remove the A-arm from the vehicle. NOTE: Remove

the shims located between the A-arm cross shaft and frame and set aside in proper order for re-assembly

Tall spindles may be used from a 1970-1976 F-Body (Camaro/Firebird) for 11” brake rotors or from a 1978+ B-Body

(Caprice/Impala) for 12” brake rotors. Regardless of which spindle is used, the lower ball joints must be matched to the

spindle. In order for these ball joint to work in the OE lower A-arm, the ball joint must be machined to the A-arm hole

dimension of 2.010”. These modified ball joints may also be purchased directly from BMR under Part# BJ001.

7. Carefully lower the jack as far as possible to remove spring tension. WARNING: stock front springs are long and may

require a spring compressor to remove safely. If a spring compressor is not available, carefully pry the spring out of the

A-arm and remove.

8. Press the modified ball joint into the lower A-arm and reinstall the arm.

9. Locate the factory upper bump stop and remove it from the frame. Install the BMR supplied polyurethane bumpstop.

10. Install the BMR upper A-arm (to properly identify the correct side, the short leg of the A-arm goes towards the front of

the vehicle). Re-install the correct shims and tighten the mounting nuts.

11. Install the new spindle assembly onto the upper and lower ball joints. Install both castle nuts and tighten. Insert new

cotter pins.

12. Install the new brake rotor with new bearings and seals.

13. Install the new caliper and rubber brake line.

14. Re-install shock. Repeat steps 3-13 for other side.

15. Install wheels/tires and align.

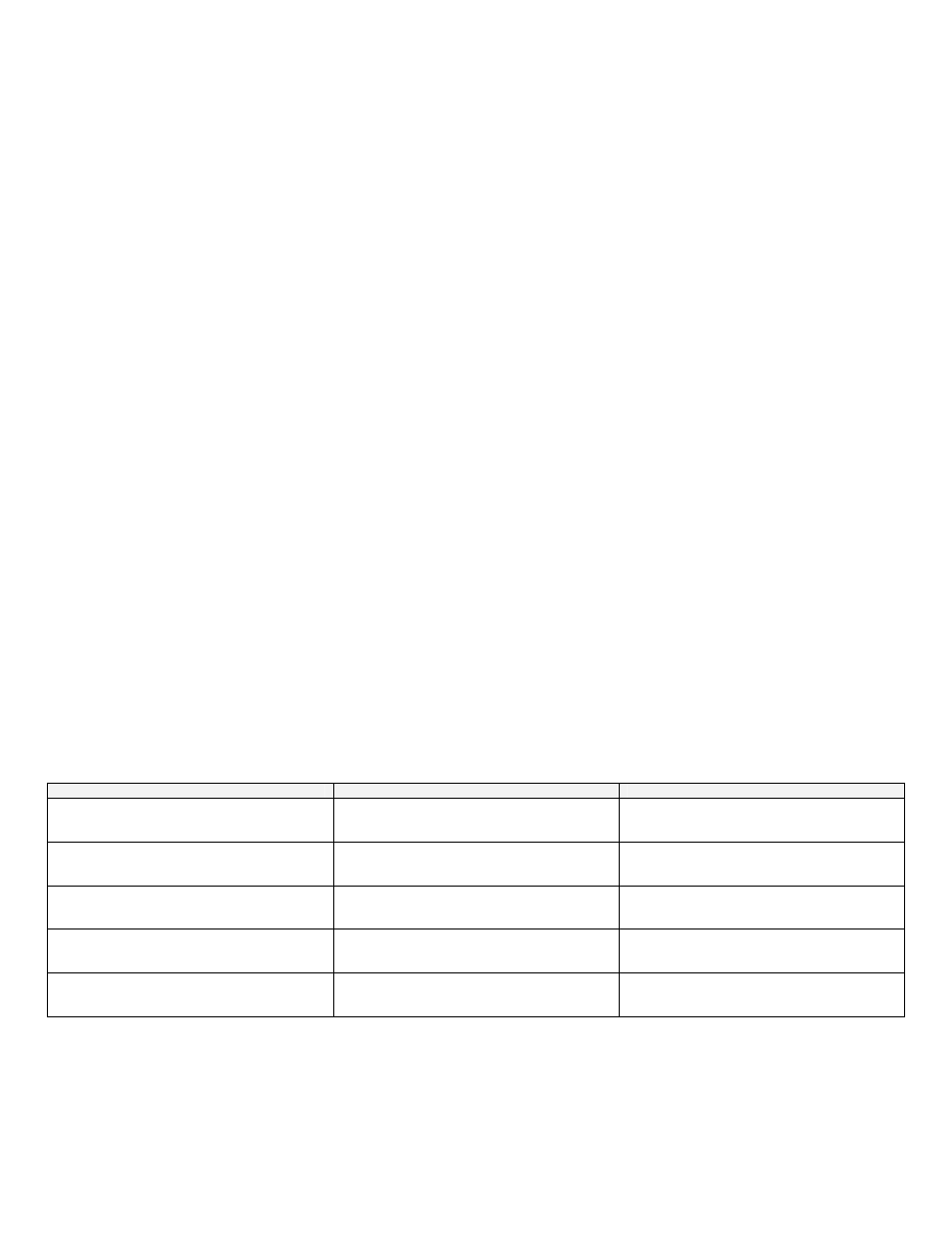

Recommended alignment settings for performance street handling applications

VEHICLE

LEFT

RIGHT

1967-1969 F-Body

Caster - 3 degrees positive

Camber – ¾ degree negative

Toe-in - 3/32” total

Caster – 3.5 degrees positive

Camber – ¾ degree negative

Toe-in - 3/32” total

1970-1981 F-Body

Caster - 4 degrees positive

Camber – ½ -¾ degree negative

Toe-in - 3/32” total

Caster – 4.5 degrees positive

Camber – ½-¾ degree negative

Toe-in - 3/32” total

1964-1972 A-Body stock spindle

Caster - 3 degrees positive

Camber – ¾ degree negative

Toe-in - 3/32” total

Caster – 3.5 degrees positive

Camber – ¾ degree negative

Toe-in - 3/32” total

1964-1972 A-Body tall spindle

Caster – 4 degrees positive

Camber – 0 degrees

Toe-in – 1/16” total

Caster – 4.5 degrees positive

Camber – 0 degrees

Toe-in – 1/16” total

1978-1987 G-Body

Caster - 4 degrees positive

Camber – 1 degree negative

Toe-in – 1/16” total

Caster – 4.5 degrees positive

Camber – 1 degree negative

Toe-in – 1/16” total

WWW.BMRFABRICATION.COM

This product is an aftermarket accessory and not designed by the vehicles manufacturer for use on this vehicle. As such, buyer

assumes all risk of any damage caused to the vehicle/person during installation or use of this product.

PAGE 3