Aa016 – 64-72 a-body, Www.bmrsuspension.com, Lower a-arms (continued) – BMR Suspension AA016 User Manual

Page 2

2

LOWER A-ARMS (Continued)

AA016 – 64-72 A-BODY

15. Re-install the caliper.

16. Repeat steps 2-16 for the other side.

17. To re-connect the sway bar, it is necessary to have the suspension loaded. The simplest way to do this is

to drive the vehicle up onto ramps. Install the wheels and tires.

18. Drive the vehicle onto ramps then re-install the sway bar end links.

19. While the suspension is loaded, tighten the lower control arm bushings. NOTE: the vehicles weight

should be on the suspension before tightening the control arm bolts. Failure to do so can result in

improper bushing preload causing irregular ride height and accelerated bushing wear.

20. Insert 5-6 pumps of grease into the lower ball joint. Insert 3-4 pumps of grease into each control arm

bushing.

21. Lower vehicle.

BMR A-arms have improved geometry built into the A-arms. Your BMR A-arms have an additional 2 degrees

of positive caster built into the arm which will affect your alignment. It is necessary to have the vehicle re-

aligned after this installation. BMR recommends the following alignment specifications:

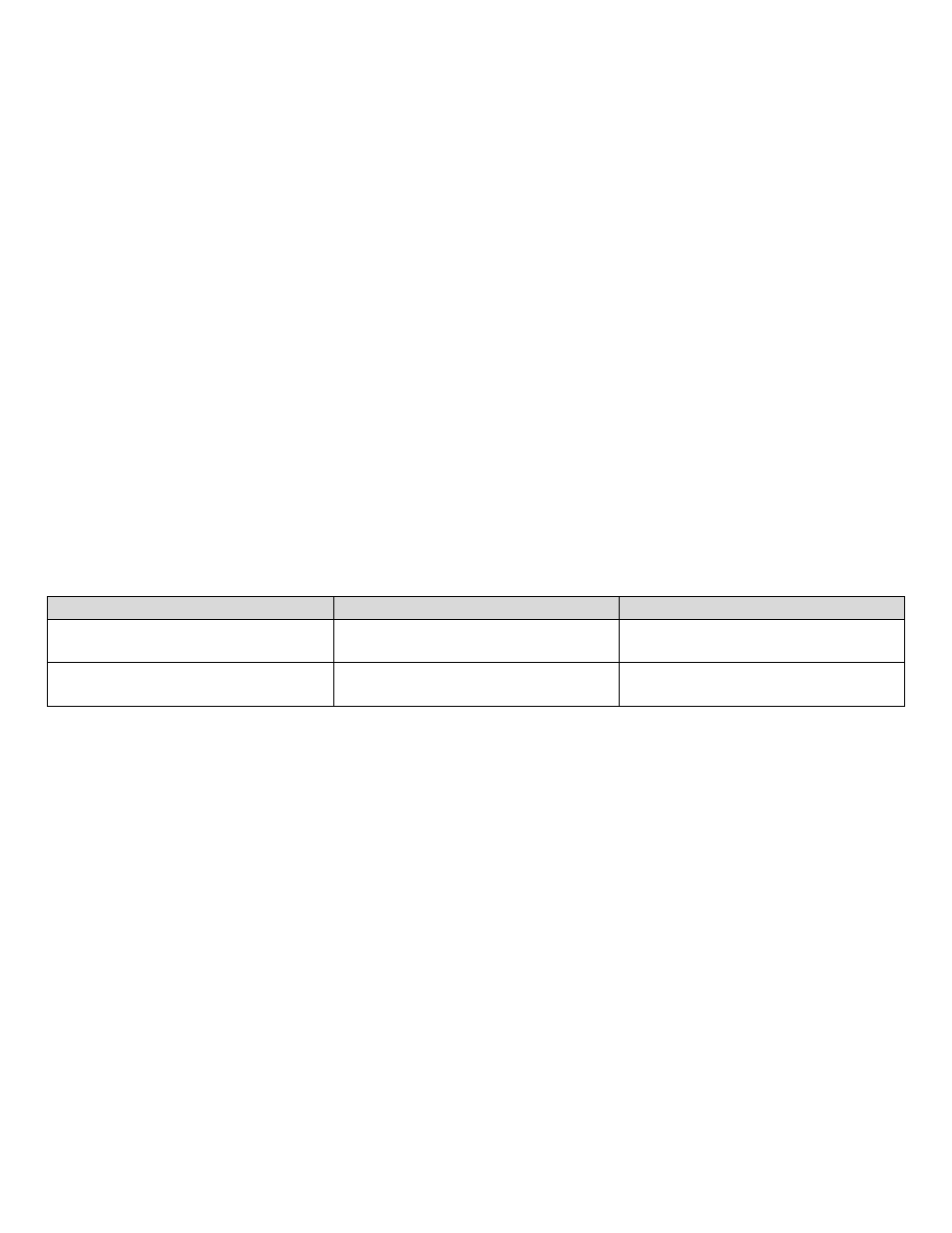

RECOMMENDED ALIGNMENT SPECS

Camber

Caster

Toe

Daily driver street – .3-.5 degrees

negative

Max positive caster to achieve

desired camber settings

1/16” Toe-in

Performance street - .5-.8 degrees

negative

Max positive caster to achieve

desired camber settings

1/16” Toe-in

WWW.BMRSUSPENSION.COM

This product is an aftermarket accessory and not designed by the vehicles manufacturer for use on this vehicle. As such, buyer assumes all risk of

any damage caused to vehicle/person during installation or use of this product.

2