Sterlco 2016C (Former Compact Series) User Manual

Page 42

Page 42

2016-C Series Hot Oil Portable Temperature Control Units

3. Coat idler pin with non-detergent SAE 30 weight oil and place

idler and bushing on idler pin in head. If replacing with carbon

graphite bushing, Refer to Installation of Carbon Graphite

Bushings, page 50.

4. Using a .010 to .015 inch head gasket, install head and idler

assembly on pump. Pump head and casing were marked before

disassembly to insure proper reassembly. If not, be sure idler

pin, which is offset in pump head, is positioned toward and

equal distance between port connections to allow for proper

flow of liquid through pump. Tighten head capscrews evenly.

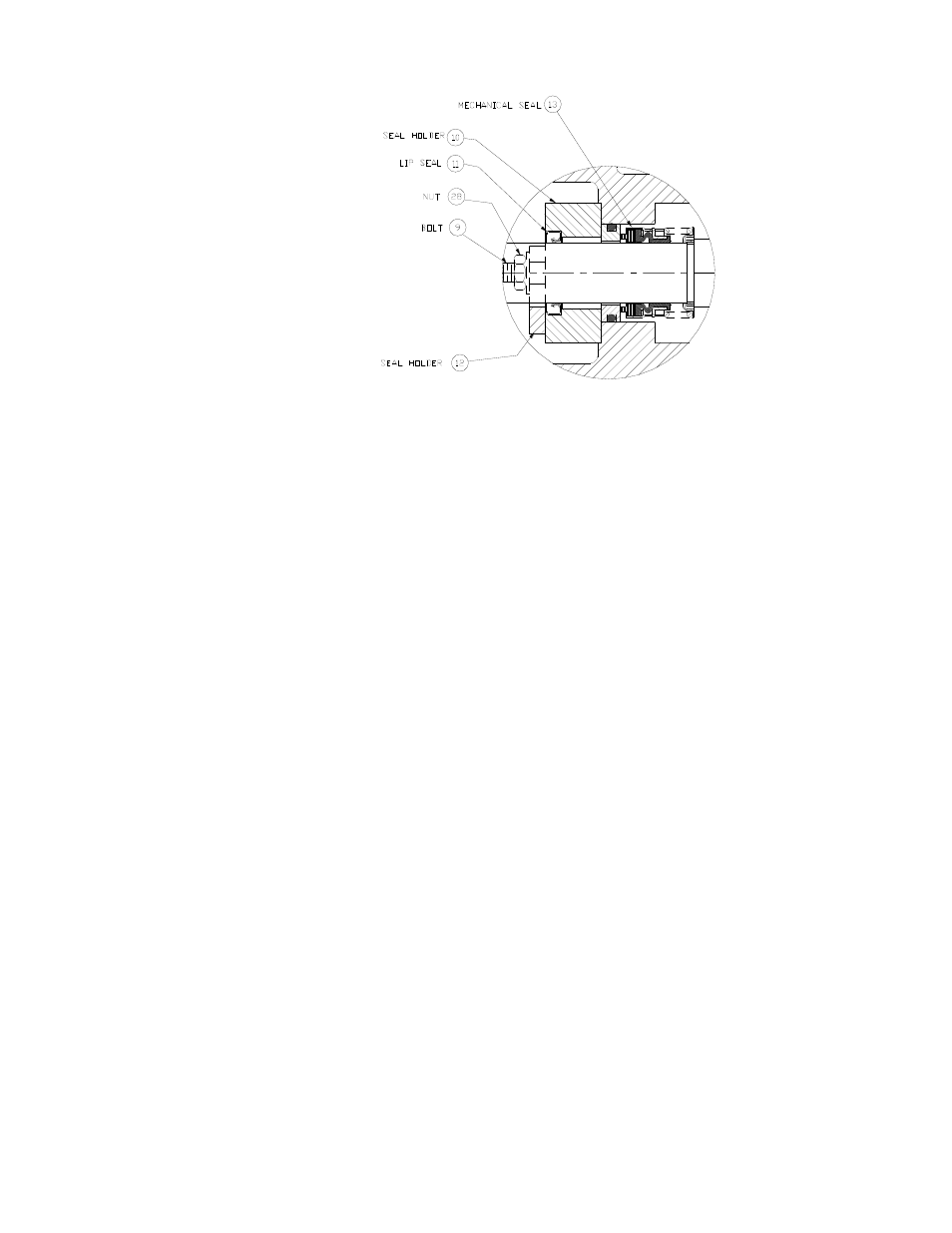

5. Place the mechanical seal installation tapered half rings over

the shaft and apply P-80 oil supplied with the replacement seal,

grease is not recommended on the sleeve and rotor shaft.

Slide the rotating portion of the mechanical seal on the shaft

until it bottoms on the shaft step. See Figure 5. Remove the

seal installation tapered half rings. It is important when using

the rings to make sure the thin edge is facing the direction of

the shaft end, and that the thick end is facing the rotor.

6. Apply lubricant to the seal seat o-ring and push it in the

bracket. Note the shinny side of the seat goes towards the

carbon graphite seal face.

7. Apply Dow Corning #44 high temperature silicon grease to the

lip seal area in the seal gland and install on the shaft. Install

the seal gland plate and secure with two nuts.