Piping considerations for mobile installations – Sterlco 2016C (Former Compact Series) User Manual

Page 19

COT-C Series Hot Oil Portable Temperature Control Units

Page 19

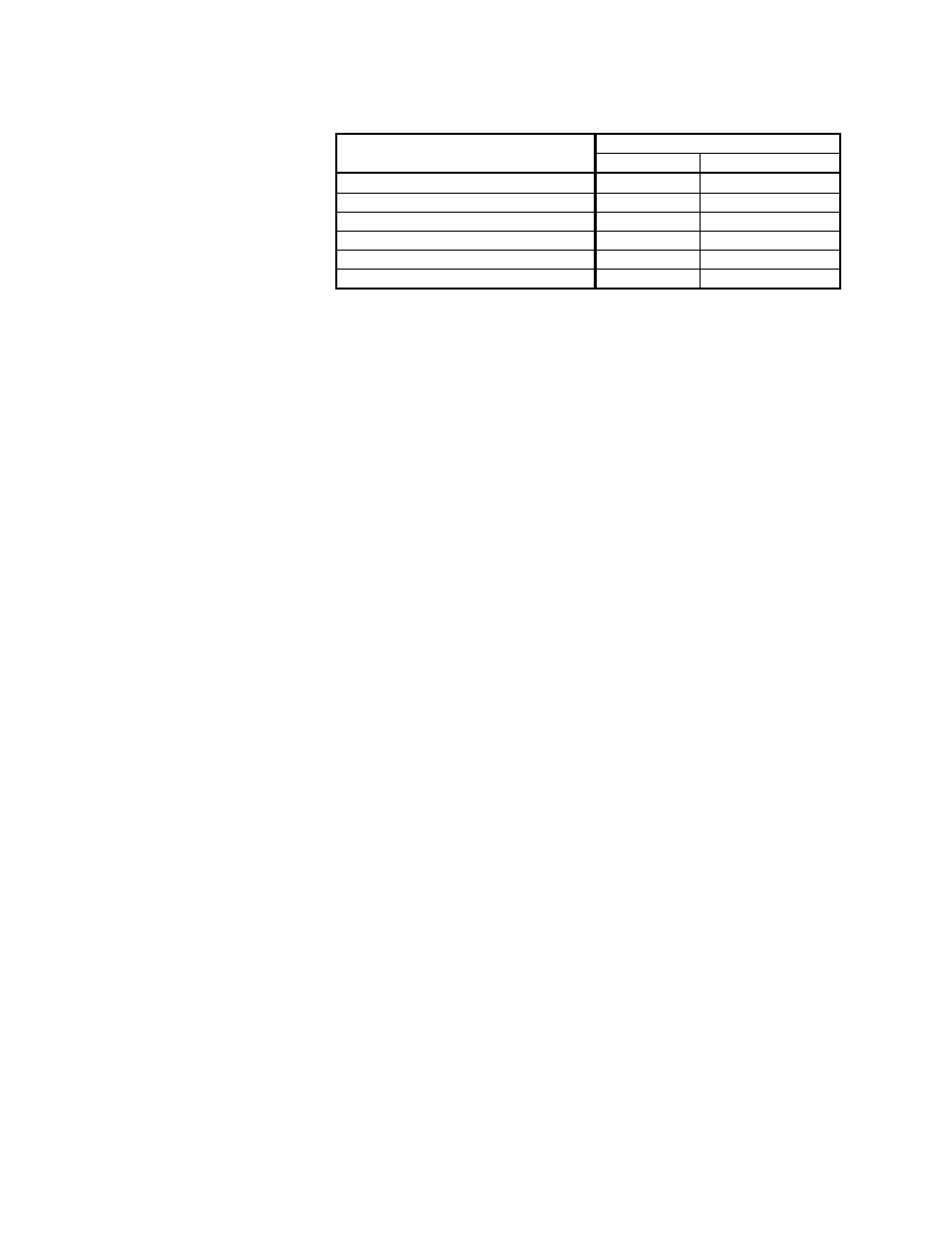

The following table lists TCO/TCU pipe sizes.

Size diameter

Connection

inches NPT

mm (approx.)

To Process

0.5

” NPT

12.5 mm

From Process

0.5” NPT

12.5 mm

Cooling Water Supply

0.5” NPT

12.5 mm

Cooling Water Drain

0.5” NPT

12.5 mm

Oil Drain

0.5” NPT

12.5 mm

Fill Port

0.5” NPT

12.5 mm

Customer is responsible for converting to metric.

Notes: Always use a backup wrench to support 2016-C unit piping

when making connections. Make sure all external piping is

supported independently of the 2016-C unit.

STERLING, Inc. recommends that you have strainers

installed on the cooling water inlets and customer-supplied

shut-off valves on all piping connections. Use common

black welded pipe for permanent installations.

The 2016-C is designed to operate with an open,

unrestricted drain line. Steam rapidly expands within the

heat exchanger, so any overpressure condition from

backpressure or standing columns of water against the drain

must be avoided.

If you must use a pipe joint compound, use a compound that can

withstand the high temperatures and pressures of your 2016-C unit.

Always insulate all piping to prevent burn hazards and to retain

heat. Make sure insulation is properly rated for maximum

operating temperatures of your 2016-C unit.

Piping Considerations for Mobile Installations

Because your 2016-C unit is fitted with casters, its portability is

well suited for multiple applications. You can purchase high-

quality flexible metal hose from STERLING to enhance the

mobility of your 2016-C unit; state the length you want when

ordering.

Although they cause a drop in pressure, you can also install quick

disconnects to your 2016-C unit. However, do not install check

valves with quick disconnects unless absolutely necessary!