Maintenance, 1 self diagnostics – Setra System Model 595 User Manual

Page 8

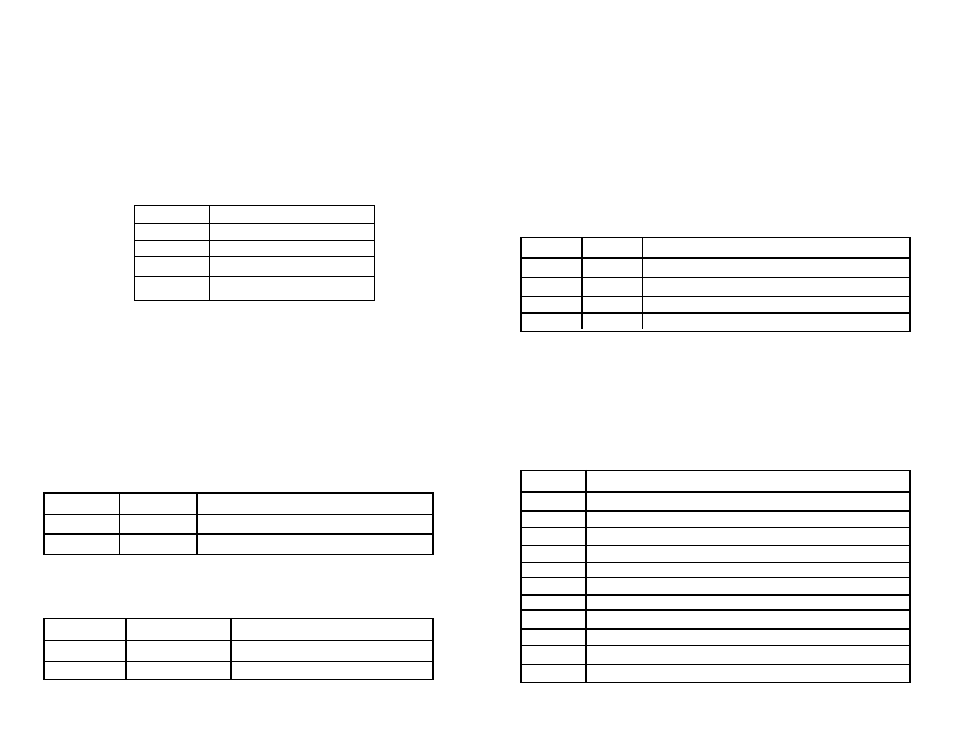

7.2.4 Setting Up a Custom Unit Scaling

Unit conversion performed by the 595 is of the form y=mx+c. Where units other

than the commonly used set provided are required then the m and c can be

written directly. This is achieved via the command aXUn,

represents the variable to be written with the following value as detailed in

Table 7.

Table 7

Variables Used for Unit Conversions

Value of n

Variable Written

0

Pressure Units Slope = m

`

1

Pressure Units Offset = c

2

Temperature Units Slope = m

3

Temperature Units Offset = c

The value of m should be calculated as follows:

For Pressure:

m = (Full Scale in User Units – Zero Scale in User Units)

(Full scale in mH

2

O at 4

°C – Zero Scale in mH2O at 4°C)

For Temperature:

m = (Full Scale in User Units - Zero Scale in User Units)

(Full Scale in

°C – Zero Scale in °C)

The appropriate values can then be written as show in Tables 8 and 9.

Table 8

Setting the Pressure Units to mbar

Command

Response

Comment

aXU0,98.0665!

a0

Sets the slope m to 98.0665, equivalent to mbar.

aXU1,0!

a1

Sets the offset to 0 as 0 mbar = 0mH

2

O at 4

°C

Table 9

Setting Temperature Units to Kelvin

Command

Response

Comment

aXU2,1!

a1

Sets the slope m as same as

°C

aXU3,-273!

a1

Sets the offset to -273 to read in Kelvin

7.2.5 Obtaining Maximum and Minimum Measurements

The 595 supports the following additional measurements via the measure and

concurrent measurement commands.

aM1!

=

Maximum Level / Pressure

aM2!

=

Minimum level / Pressure

aM3!

=

Maximum Temperature

aM4!

=

Minimum Temperature

The maximum and minimum values should be reset using the XMM command

as shown in Table 10.

Table 10

Resetting Maximums and Minimums

Command Response Comment

aXMM1!

a1!

Resets the maximum level to the current value

aXMM2!

a2!

Resets the minimum level to the current value

aXMM3!

a3!

Resets the maximum temperature to the current value

aXMM4!

a4!

Resets the minimum temperature to the current value

8. Maintenance

8.1 Self diagnostics

The 595 performs a significant amount of self-diagnostics upon reception of the

verify command, aV!. It is recommended that any system design should include a

periodic execution of the verify command. The response to a verification com-

mand includes an error code. Table 11 summarizes the possible error codes from

the verification command.

Table 11

Diagnostics

Error Code

Description

0

No Error, unit is functioning normally

1

The temperature measurement is beyond the calibrated range

2

The pressure measurement is beyond the calibrated range

4

The nonvolatile memory has been incorrectly accessed

8

An analogue signal error exists

16

Reserved

32

The nonvolatile user data is in error

64

The nonvolatile calibration data is in error

128

RAM error

256

Watchdog error

Note: If an error code >3 is returned, record the value and contact the manufacturer