Maintenance, Repairs, Fault possible causes – FUTEK TRS-Series User Manual

Page 17: Solution

17 EM1005

6. Maintenance

TRD/TRH/TRS Series sensors are almost maintenance-free where the bearing needs to be

replaced by factory after its life time.

Durability of bearings in compensated temperature range is approx. 20,000 hours.

Durability of bearings in operating temperature range is approx. 10,000 hours.

For Precision applications: Calibration of the sensor should be done at FUTEK or with adequate

calibration equipment.

Calibration: Yearly calibration is recommended but it depends on the criticality of the application &

requirement and may require smaller calibration intervals.

Inspect torque sensor cable and mating connector for damage on a monthly basis.

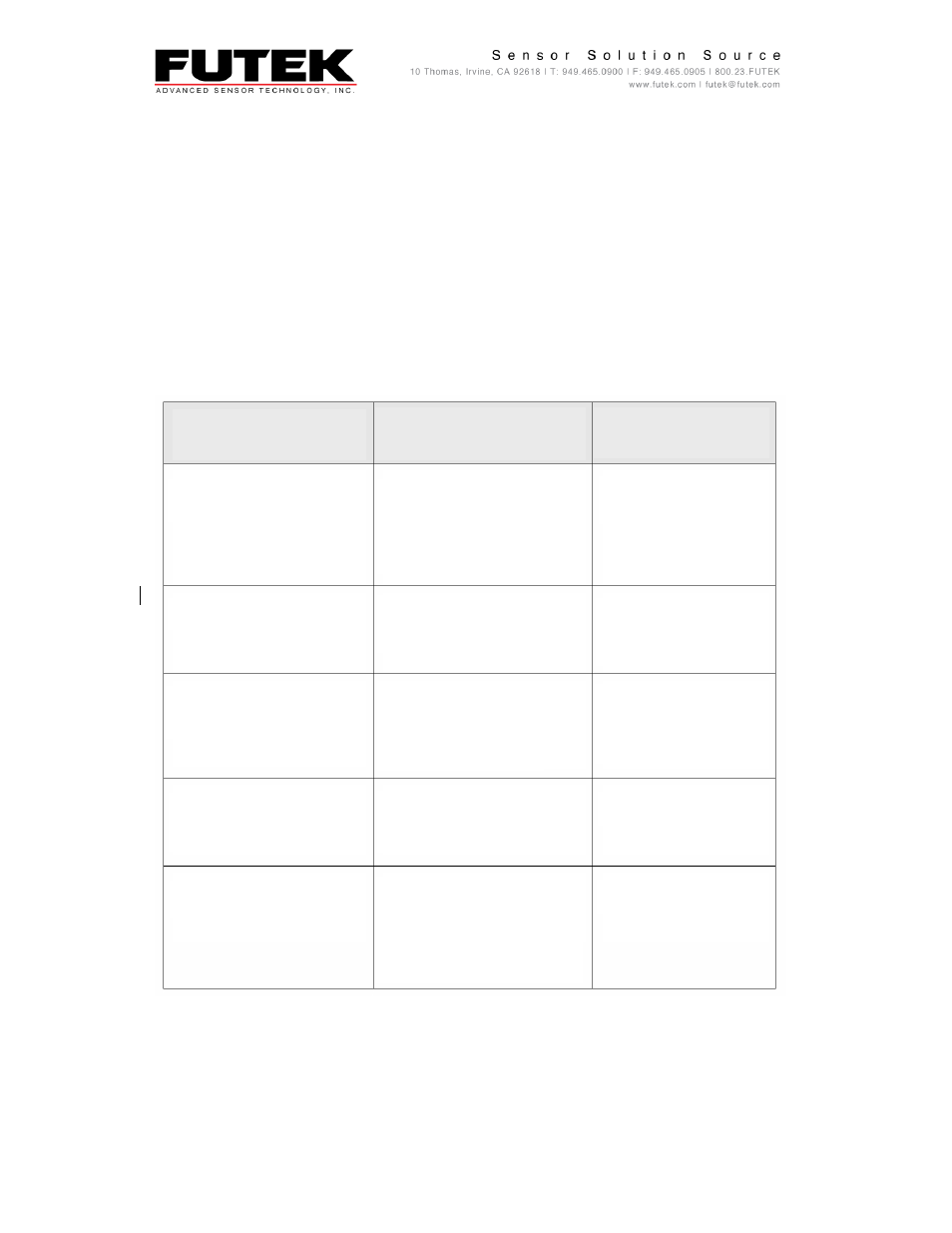

7. Repairs

Shaft stiff to turn

Bearing failure due to:

a) Torsional or flexural

vibration

b) High axial or radial loads

c) Worn bearings

d) Bent shaft

Return to factory

Fault

Possible Causes

Solution

Zero shift less than 2%

Torsional vibration

Torsional Shock

The zero reading may be

re-adjusted at display

Zero shift between approx.

2 and 5% of full scale

Zero shift more than 5%

Torque sensor has been

overloaded

Torsional vibration

Torsional shock

Torque sensor overloaded by

high alternating loads or

torsional vibration

The zero reading may be

re-adjusted at the

display

Return to factory

Return to factory

Torque sensor overloaded by

high alternating loads or

torsional vibration

Hysteresis between

clockwise and counter-

clockwise torque