Dwyer FS User Manual

Page 6

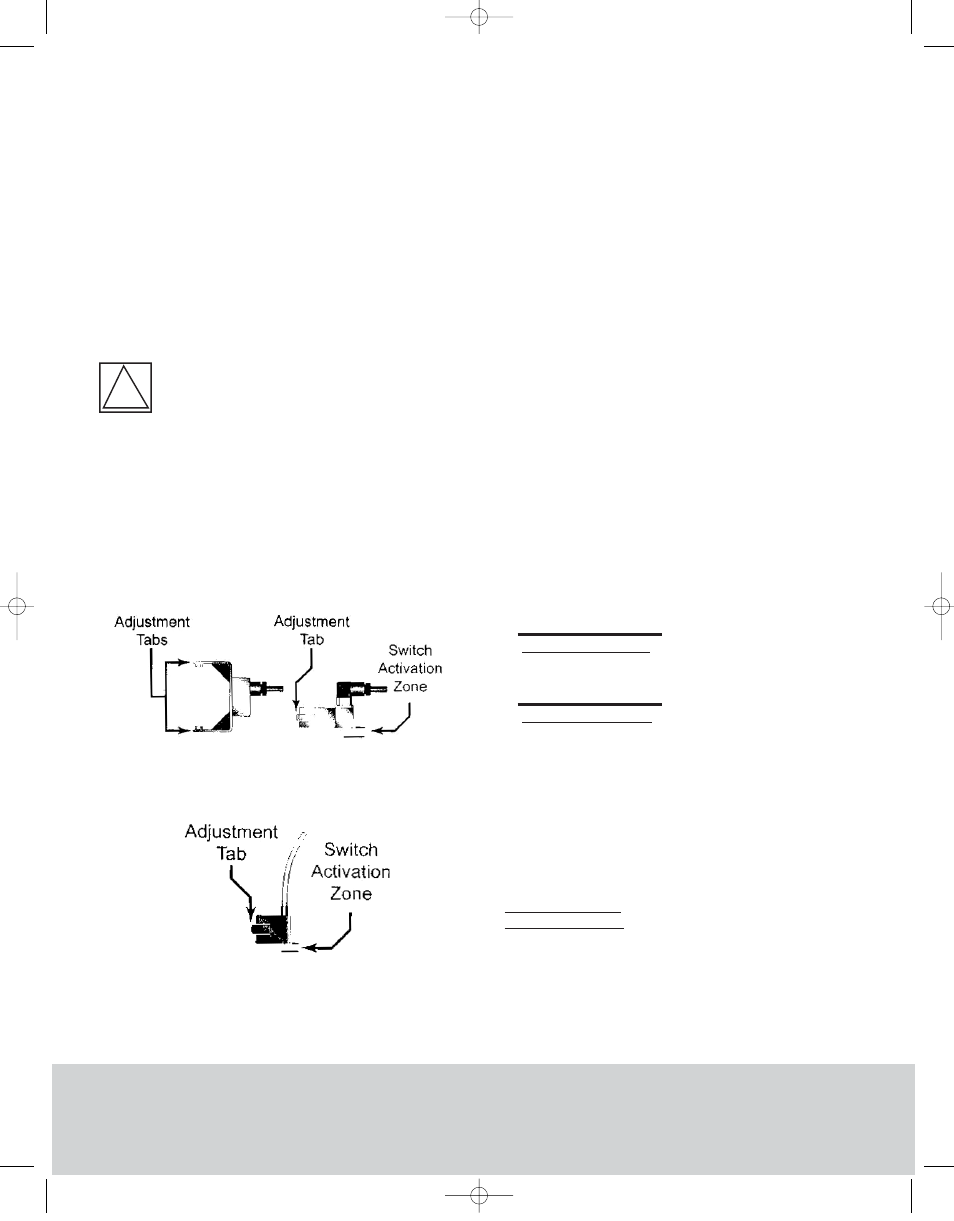

SWITCH ADJUSTMENT

After the flow meter has been installed and the switch

wired, the flow rate at which the switch will activate must

be adjusted. Figure 17 shows the activation zone for the

latching switches and Figure 16 shows the activation zone

for the reed switch variation.

1) With fluid running through the meter set the flow to the

rate you wish the switch to activate.

2) Gently move the switch adjustment tab(s) outward until

the switch body is free to slide up or down on the

serrated rail.

3) Move the switch into position until the switch activates.

4) Release the switch adjustment tab(s) to lock the switch

into position.

Warning - Fail-safe operation - If the flow

meter and switch are to be installed in a critical

application be sure the system is fail-safe. The

switch should be wired such that any switch

failure will stop the system. Failure to fail-safe the system

may lead to system damage and/or injury to personnel.

FLUID CORRECTION - LIQUIDS

Standard Flow

Scales

Standard liquid flow scales are calibrated in gpm and lpm

at 0.876 specific gravity for petroleum-based fluids and

1.0 s.g. for water and water-based fluids. For field

conversion of the standard scale to other fluids, see

ammonia example listed below.

Special Flow Scales

Special scales are available for liquids and gases in any

measurement unit, and other fluid viscosities and/or

specific gravities.

Viscosity Effect (SUS/cSt)

This variable area design utilizes a precision molded,

sharp-edged orifice and biasing calibration spring that

assures operating stability and accuracy over the wide

viscosity range common to many fluids. Generally, high

flow models provide good accuracy over a viscosity range

of 40 to 500 SUS (4.2 to 108 cSt).

Density Effect (specific gravity)

Any fluid density change from stated standards has a

square-root effect on meter accuracy. Special scales can

be supplied if actual specific gravity decreases accuracy

beyond application limits.

Corrections for more or less dense fluids can be made to

standard scales using correction equations as follows.

For water and water-based meters

For petroleum-based meters

Example: Measuring Gasoline with a petroleum based

meter

Fluid: Gasoline

Measured Flow From Scale: 28.5 GPM

Select (Gasoline) specific gravity from Fluid Selection

Chart.

S.G (LPG) = 0.70

Since a petroleum meter is being used, select the

petroleum-based formula.

1.119 (Correction Factor x 28.5 (Inducted Flow of

Gasoline = 31.88 (Actual Flow of Gasoline).

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057

e-mail: [email protected]

!

Figure 17

Figure 18

√

√

1.0

Specific Gravity

0.876

Specific Gravity

√

0.876

0.70

=1.119

FS 12/4/03 2:15 PM Page 6