Dwyer FS User Manual

Series fs flowmeter with limit switch, Bulletin # f-41-fs, Dwyer instruments, inc

Specifications - Installation and Operating Instructions

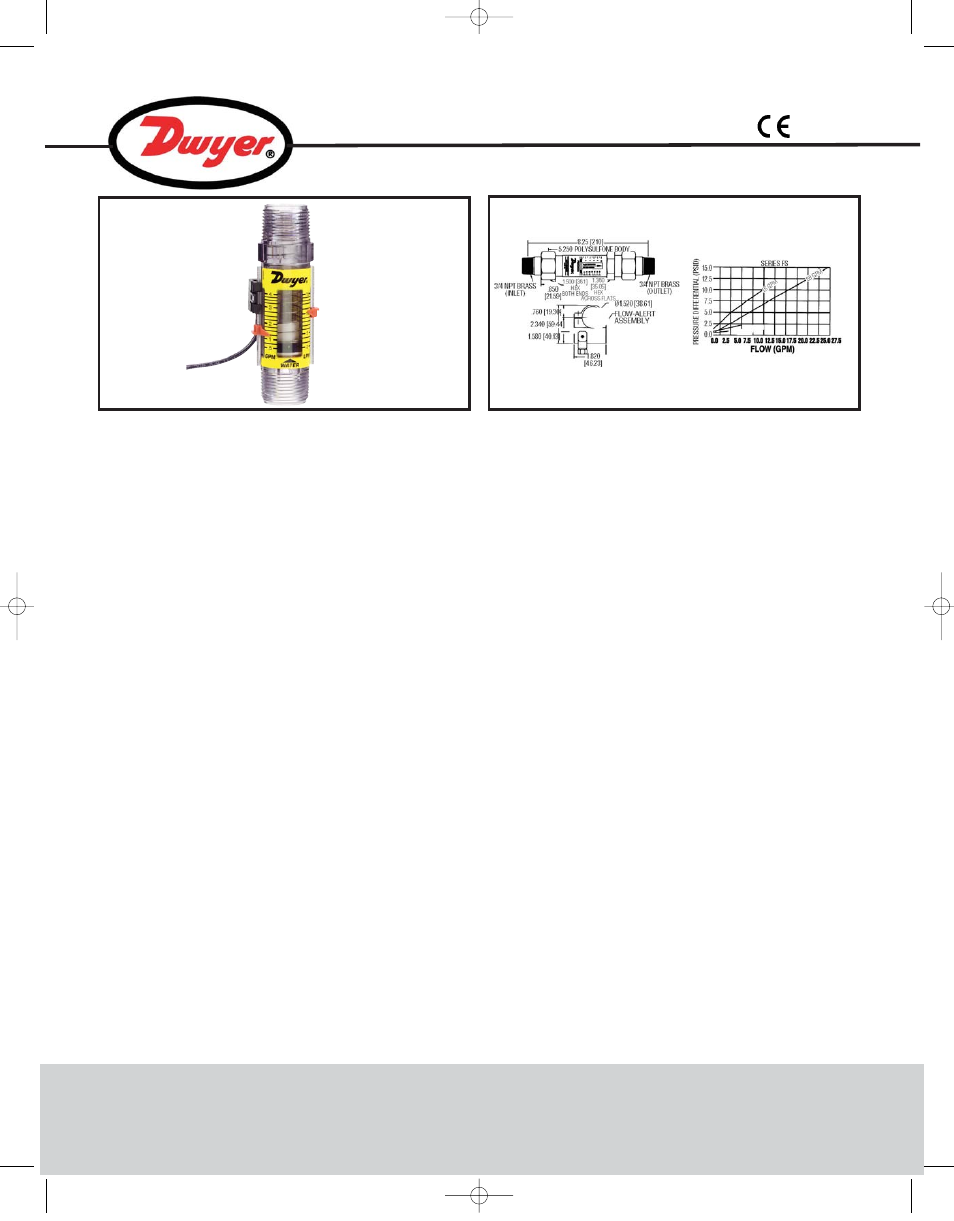

DESCRIPTION

Industrial

Direct-Reading Series FS Flowmeters are

rugged, low cost, and simple to install. The Series FS

offers visual flow rate indication and an adjustable flow

alarm to open or close AC electrical circuits, trigger

warning lights, or activate other process control

equipment. Operating within ±5% of full scale accuracy,

the Series FS can be installed vertically or horizontally

without installing any special plumbing. The Series FS is

constructed of high impact resistant polysulfone. This

series offers excellent structural integrity against operating

pressures up to 325 psi (22.4 bar) for liquids and 125 psi

(8.6 bar) for gases. The Series FS can withstand fluid

temperatures up to 250°F (121°C) and is compatible with a

wide range of chemicals.

Bulletin # F-41-FS

Series FS Flowmeter with Limit Switch

PHYSICAL DATA

Accuracy: ±5% Full Scale.

Repeatability: 1.0%.

Set Point: Adjustable 0 to

100% FS.

Pressure Limits: 325 psi (22.4

bar)

Temperature Limits: 250°F

(121°C).

Supply Voltage: 115 VAC, 140

VAC max.

On-State Current: 0.02 to 1.0

A AC.

Connections: 1˝ male NPT

Polysulfone or

3

/

4

˝ male NPT

Brass.

Flow Scale: Calibrated at 1.0

specific gravity @ 70°F (21°C).

Wetted Materials: Polysulfone

body, Barium Ferrite, Stainless

Steel spring and retaining

rings.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057

e-mail: [email protected]

TO OPEN FLAMES OR EXCESSIVE HEAT. The meter may

melt, crack, or distort. Some pipe dope formulas will react

adversely with polysulfone. Use Teflon

®

tape as if sealing

material is necessary.

The Series FS can be mounted in any plane of orientation.

Horizontal or vertical mounting does not effect flowmeter

accuracy. The inlet and outlet of the flowmeter should be

aligned, particularly when high temperature, high

pressure, or a combination of both may be encountered.

Install the flowmeter in the direction of the indicating

arrow on the scale. The Series FS Flowmeter does not

require lengths of straight pipe at the inlet, or outlet, to

stabilize flow through the meter. These meters can

tolerate particles that normally will jam other flow controls.

If large amounts of particulates are encountered, a 200

mesh or 74 million micron filter is recommended.

A separate four conductor female connector is supplied

with the limit switch assembly. The connector must be

disassembled to solder wired onto it. See Figure 1. the

Connector has four solder lugs labeled 1, 2, 3, and 4.

Terminals 3 and 4 are not used. It should be noted before

reassembly, which wire is connected to which solder plug.

Color coding or labeling the wires is advised. Secure

OPERATING PRINCIPLE

The Series FS is a piston-type variable area flow meter

that uses a sharp-edged annular orifice formed between

an open-centered piston and tapered metering cone. the

piston is held in a “no flow” position at the base of the

cone by a precision retention spring. Flow through the

meter creates a pressure differential across the piston

orifice, moving the piston against the spring. Piston

movement and orifice area are proportional to the rate of

flow. Therefore, the greater the rate of flow, the further the

piston moves along the tapered metering cone. The flow

rate is measured by the viewing the red indicator ring

mounted on the piston relative to a graduated flow scale

affixed to the outer surface of the flow meter body.

MECHANICAL INSTALLATION

CAUTION: DO NOT OVER TIGHTEN THE THREADS ON

THE PLASTIC BODY. Overtightening the NPT threads may

cause fracturing of the plastic flowmeter body. The

flowmeter is constructed of polysulfone and remains

stable to 210°F (99°C). DO NOT EXPOSE FLOWMETER

FS 12/4/03 2:15 PM Page 1