Dwyer STFLO User Manual

Page 2

RECOMMENDED PIPING

Series STFLO Stainless Steel Flowmeters generally have no special

straight run or other piping requirements. Inlet piping should be the same

size as the meter connection. Some effect on meter accuracy may occur

at high flow velocities if inlet piping guidelines are violated. Please refer

to the table on the next page. When installing on different size pipe, use

standard pipe adapters and come into the meter inlet with a nipple 8

diameters long of the same size for greatest accuracy. Control valves

should be mounted on the outlet side of the meter. The use of a three

valve manifold around the meter is suggested, as it allows uninterrupted

process flow while the meter is being cleaned.

PLUMBING-IN

While the flowmeters should be vertical, exact plumbness is not

necessary. A general rule is that if the meter appears plumb, it is close

enough (even if off by 10º, the predictable reading error is usually less

than 1%). Pipe should be cut to proper lengths to avoid stress on the

meter. Avoid over-tightening, and do no use wrenches on the body or

reading scales. If using solvents in the vicinity of reading scales, the

scales should be removed until fumes clear.

SURGE & WATER HAMMER PREVENTION

Operating Limits are for non-shock conditions only. Flowmeters are more

accurate and less likely to be damaged when the fluid flow is smooth.

Water hammer is a hazardous phenomenon and should be eliminated

from any fluid system. Water hammer is a series of pressure shocks

create by a sudden change in the flow velocity of liquid in a pipe. This

sudden change, often caused by a fast acting valve or starting, stopping,

or change in speed of a pump, generates an immediate rise in pressure

that sometimes makes a noise similar to striking the pipe with a hammer.

The pressure wave is transmitted from the source throughout the

system, subjecting every component to the sudden shock. Pressure

returns to normal only when a larger vessel or pipe section is reached,

the energy dissipated thru friction and pipe expansion, or some

component ruptures. Rupture of piping, valves, flowmeters, or other

components have obvious safety ramifications that must be addressed.

SURGE CHAMBERS & ACCUMULATORS

Flowmeters are more accurate and less likely to be damaged when the

fluid flow is smooth. If the meter must be installed on a line where

reciprocating pumps causing pulsation are used, surge chambers,

accumulators, or desurgers are strongly suggested to dampen the shock

wave. This is a good, general practice for all flowmeters.

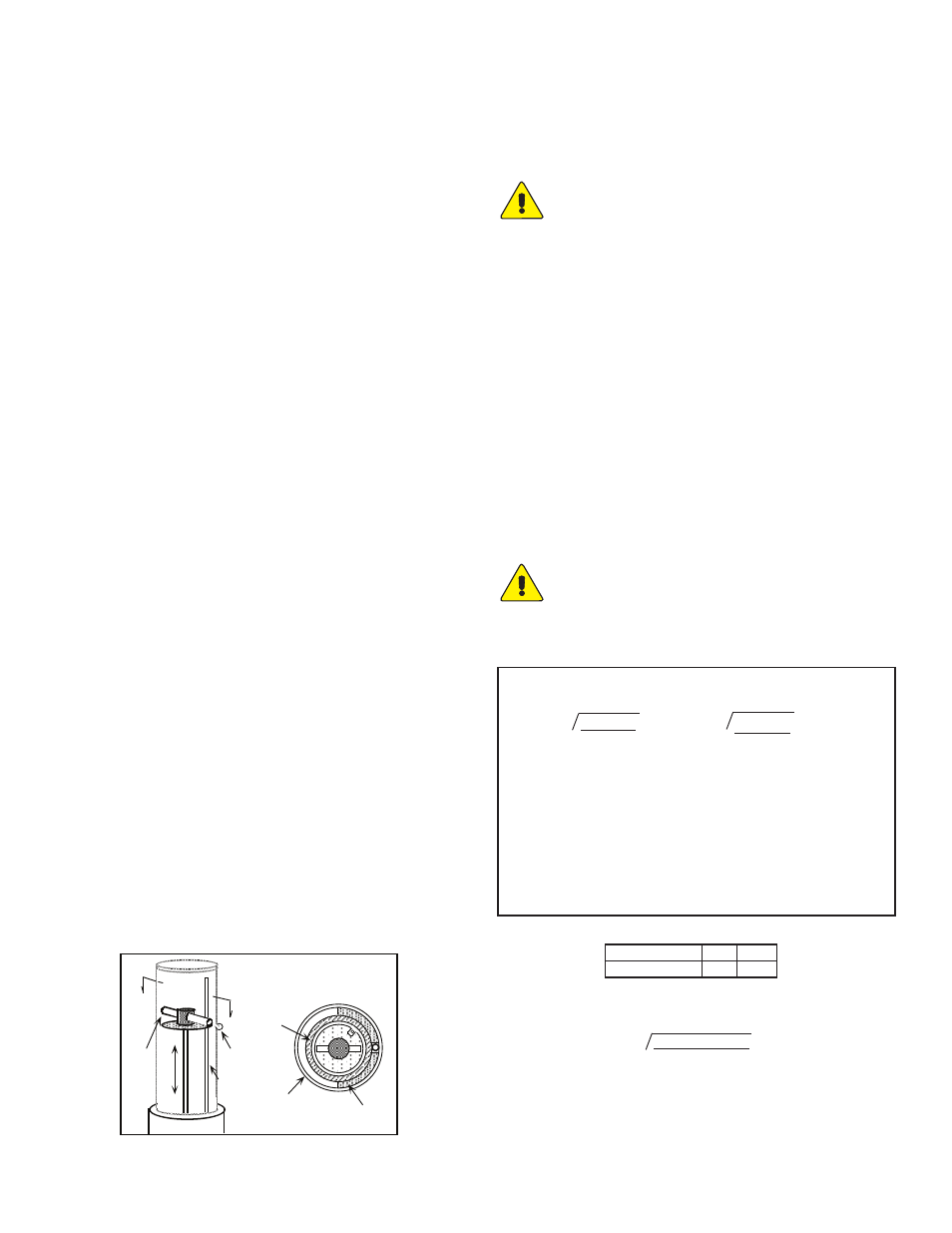

READING SCALES ROTATION

Series STFLO Stainless Steel Flowmeters use magnetically-linked ball

indicators and the scale may be positioned over approximately a 300 ˚

range. However, the magnet position must also be changed accordingly,

requiring removal of the reading scales (see “Disassembly”). On

standard STFLO Stainless Steel Flowmeters as depicted in Figure 1, the

magnet slides out of the carrier at the top of the float assembly. The

screw holding the carrier to the float may be loosened to allow rotation

of the carrier toward the desired scale location. Re-tighten the screw

(thread sealant is recommended), replace magnet, and reassemble the

meter (see “Assembly”). Verify that the ball indicator has been “captured”

by the magnet. If not, rotate the reading scales until the ball is “grabbed”

by the float magnet.

SEC A-A, TOP VIEW

METAL

PRESSURE

TUBE

PHENOLIC

RACEWAY

A

A

MAGNET

BALL

INDICATOR

SNORKEL-

GUIDE

READING

SCALES

FIGURE 1

STARTUP

System flow should be started with the bypass valve open and meter

inlet and outlet valves closed. After the system is operating, open the

meter inlet valve gradually to equalize internal pressure. Then slowly

crack meter outlet valve and wait for float to stabilize. Finally, slowly

open the meter outlet and/or flow regulating valve all the way and close

the system by-pass valve.

AVOID SUDDEN SURGES THAT CAUSE THE METER

FLOAT TO SLAM INTO THE TOP OF THE READING

SCALES!

Although not essential, the meter reading scales should be filled to a

level above the float on liquid systems. The snorkel tube (present in most

standard models) allows escape of entrapped gases except for a small

pocket in the upper end which helps cushion hydraulic shock. To assure

proper filling and to flush any foreign particles from the meter, operate

the system at full flow briefly at startup.

READING FLOW

Read flow directly from the scale as the number nearest to the center of

the ball indicator.

COMPENSATING FOR SYSTEM CHANGES

To find the correct flow reading for a system whose fluid conditions vary

from those for which the meter is scaled, use the conversion equations

provided. The most practical method of applying the formulae is to

calculate a conversion factor for the new system condition and

multiplying the scale reading by that factor. In the problems to the right,

“Q’s” has been assigned a value of “1” to determine the conversion

factor. (Dwyer Instruments, Inc. can provide special scales at additional

cost for other fluids and/or units.)

EXAMPLE: Using a standard stainless steel meter scaled for water (ps

= 1.00), what is the conversion factor for an oil with a specific gravity of

0.85?

Thus, actual flow of the oil would be the observed scale reading times

CAUTION: DO NOT OPERATE THE FLOWMETER ON A

SYSTEM EXCEEDING THE OPERATING LIMITS OF THE

UNIT. WHEN CHANGING OPERATING CONDITIONS, MAKE

SURE THAT THE NEW SYSTEM CONDITIONS ARE WITHIN

THE FLOWMETER OPERATING LIMITS, AND ALL WETTED

MATERIALS ARE COMPATIBLE WITH THE FLUID.

CORRECTING READINGS FOR NEW LIQUID CONDITIONS

Where:

Qa=Actual flow, GPM (or same units as scale)

Qs=Meter reading from scale, (scale units)

ps=Specific gravity of calibration liquid related to water in std.

atmosphere at 70˚F being 1.00

pa=Specific gravity of metered liquid, same base

ds=Density of calibration liquid, lbs/ft3

da=Density of metered liquid, lbs/ft3

pf=Specific gravity of meter float

df=Density of the meter float as per Table below

Qa = Qs

√

Ps(Pf-Pa)

Pa(Pf-Ps)

√

ds(df-da)

da(df-ds)

or Qa = Qs

FLOAT SPECIFIC GRAVITIES/DENSITIES

Material

Stainless Steel

pf

8.05

df

501.1

=1.11

Qa = 1.00

x

√

1.00 (8.05 - 0.85)

0.85 (8.05 - 1.00)