Dwyer STFLO User Manual

Dwyer instruments, inc, Series stflo stainless steel flowmeters, Bulletin f-41-stflo

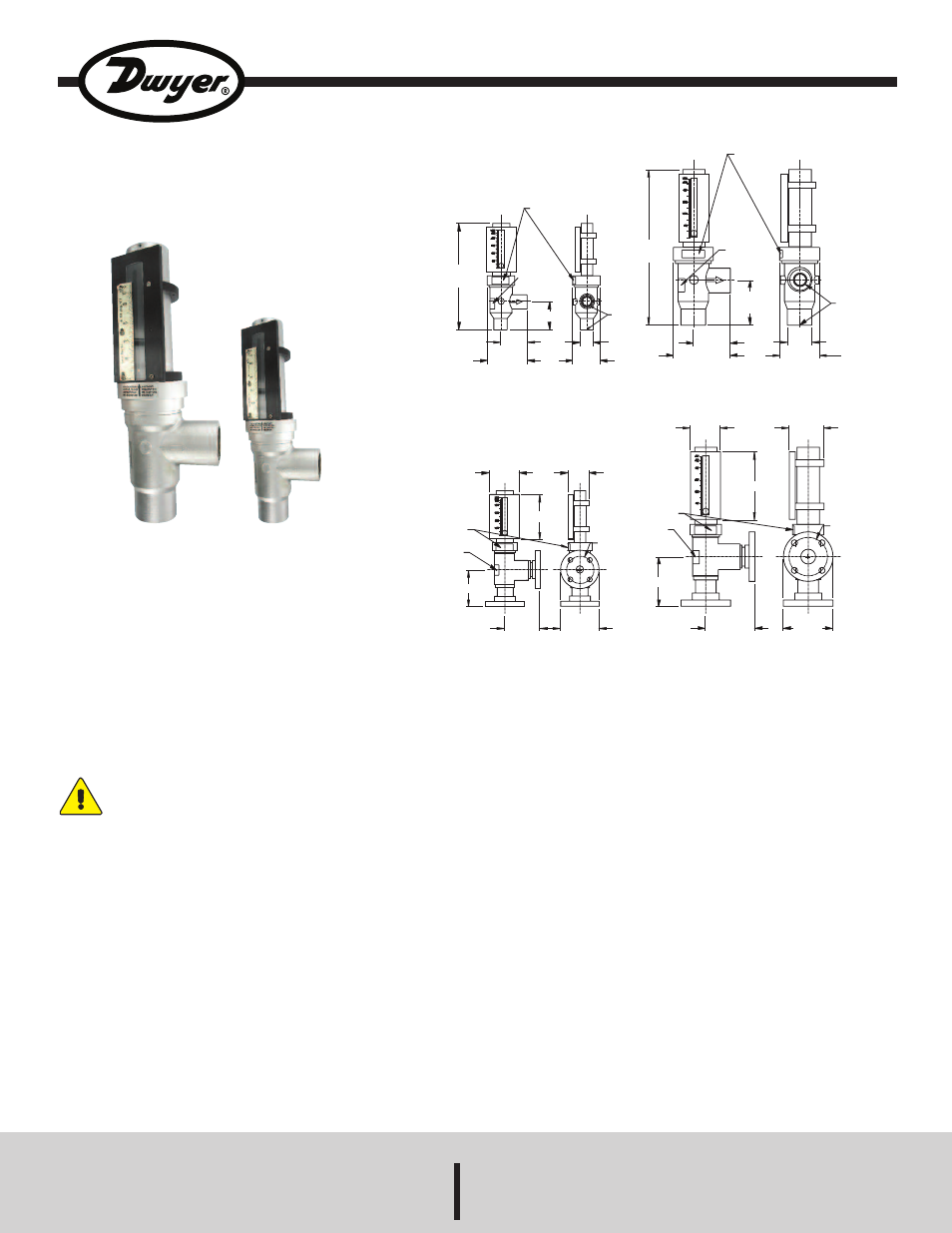

Series STFLO Stainless Steel Flowmeters

Specifications - Installation and Operating Instructions

Bulletin F-41-STFLO

Series STFLO Stainless Steel Flowmeters are ideal for dirty or

opaque fluids, high temperature and high pressure service and harsh

environments, specifically steam applications.The direct reading scale

provides ±2% accuracy. Flowmeters can quickly be disassembled

without removing the body from the pipeline for easy cleaning.

SAFETY PRECAUTIONS

Personnel safety should be considered before pressurizing and

operating the system. There are numerous possibilities for

error in system operation and maintenance as well as

component installation. Because human eyes must necessarily

come into close proximity with the flowmeter to read it, Dwyer

Instruments, Inc. recommends that safety shielding such as a

sheet of transparent, high impact material be used in front of

the meter. If hazardous, toxic, or flammable fluids are being

metered, recommended safeguard should include methods to

protect personnel from splash or rebound. A method of quick,

safe removal of dangerous fluids should also be included.

INSTALLATION

PREPARATION: Series STFLO Stainless Steel Flowmeters are ready to

install as-is, although the reading scales may need repositioning so the

scale is visible after installation. First, remove the protective caps from

the connection ports. Also, remove the plastic tubing above the inlet cap

in the meter core tube! This tubing blocks the float assembly in place

during shipment. Check that the float moves freely within the core tube,

and that no packing materials are in the meter.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057

e-mail: [email protected]

SPECIFICATIONS

Service: Compatible with liquids and gases.

Wetted Material: T316 SS, Alnico magnet, PTFE.

Temperature Limits: See chart on page 7.

Pressure Limits: See chart on page 7.

Accuracy: ±2% FS.

Repeatability: ±0.5% of indicated flow rate.

Process Connections: 3/4˝ or 1-1/2˝ female NPT, optional flange

connections.

Scale Length: 3/4˝ models: 3.2˝ (8 cm); 1-1/2˝ models: 5.2˝ (13 cm).

Weight: 3/4˝ NPT models: 5.75 lb (2.6 kg); 1-1/2˝ NPT models: 14 lb (6.4

kg). 3/4˝ Flange: 9.75 lb (4.4 kg); 1-1/2˝ Flange: 22 lb (10 kg).

4-1/32

[102.25]

2-11/16

[68.07]

IN

10-21/32

[270.78]

LABEL, SEE

DETAIL 1

3/4 NPT CONNECTION

OUT

2-13/16

[71.37]

LABEL

SEE

DETAIL 2

2-3/4

[69.95]

Ø1-11/32

[34.29]

3/4 NPT

15-21/32

[397.28]

LABEL SEE

DETAIL 1

LABEL, SEE

DETAIL 2

IN

OUT

4-1/2

[114.38]

3-23/32

[94.23]

5-11/16

[144.65]

1-1/2 NPT

Ш2-15/32

[62.99]

Ш4

[101.85]

1-1/2 NPT CONNECTION

3

[76.20]

LABEL, SEE

DETAIL 1

LABEL, SEE

DETAIL 2

5

[127.00]

4-31/32

[125.98]

5

[127.00]

6-13/16

[172.97]

3-1/2

[88.91]

Ш3-7/8

[Ш98.55]

Ш2-3/4

[Ш69.85]

2-1/8

[53.59]

3

[76.20]

4-1/2

[114.30]

LABLE, SEE

DETAIL 1

LABEL, SEE

DETAIL 2

3-11/16

[93.73]

3-9/16

[90.43]

3-7/8

[98.55]

3/4 FLANGE CONNECTION

1-1/2 FLANGE CONNECTION