Page 8 page 9 parts list, Operation – Dwyer TBS User Manual

Page 6

Page 8

Page 9

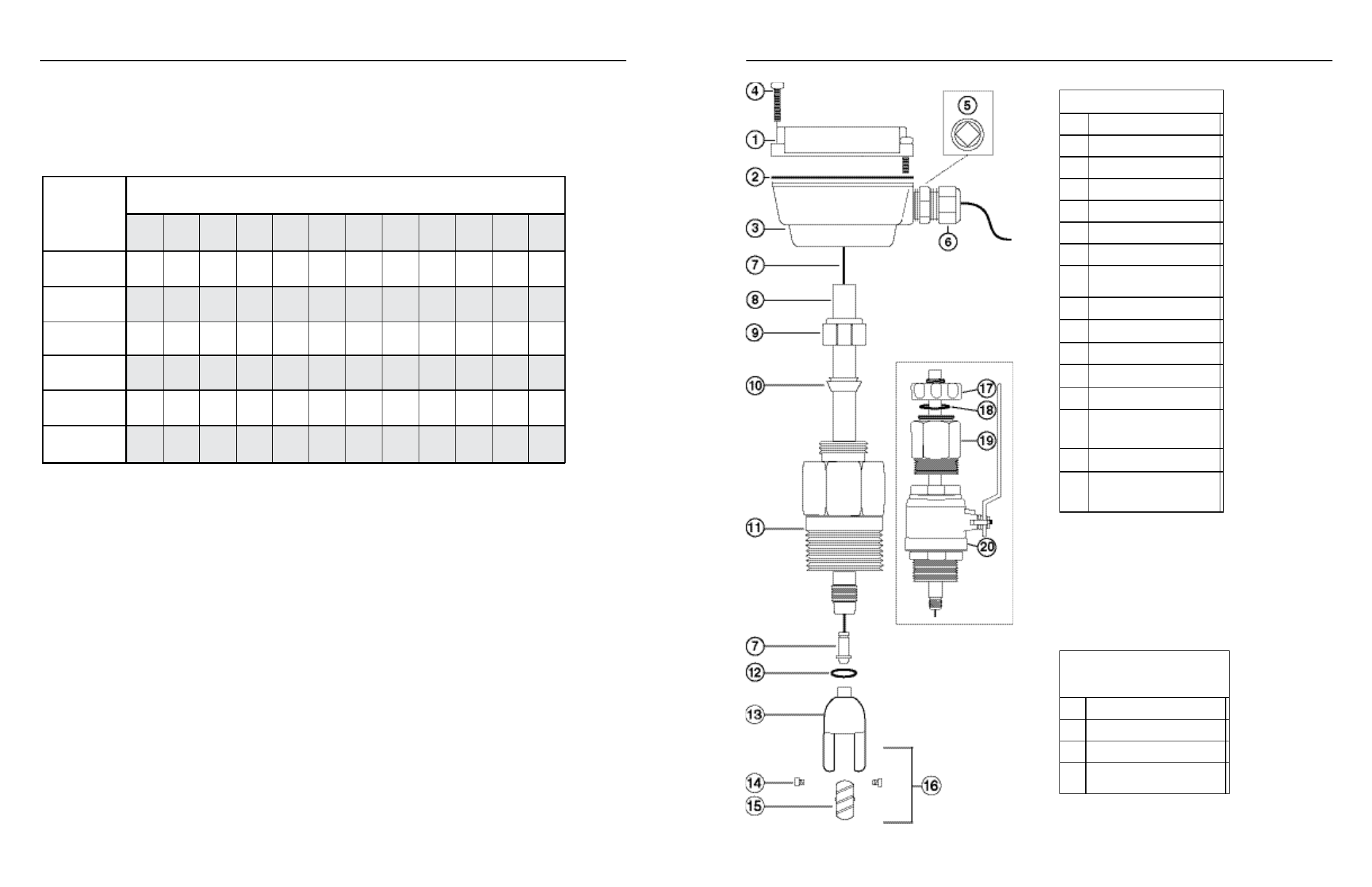

PaRTS lIST

TBs-0XX Parts

1

Upper housing assembly

2

Housing Gasket

3

Lower housing

4

Housing screw assembly

5

Plug, steel

6

Strain relief

7

Sensor w/cable

8

Tube

9

Compression nut

10

Compression Ferrule

11

Adapter fitting

12

Rotor housing O-ring

13

Rotor housing

14

Jewel bearing assembly

(for carbide shaft)

15

Turbine Rotor assembly

16

Rotor repair kit

(consists of #14 & #15)

(0.5)

(1.0)

(2.0)

(5.0)

(10.0)

(20.0)

(30.0)

TABle 4: Flow Rates converted from Feet/sec to Gallons/minute at various velocities: schedule 40 pipe

Nominal pipe size

Feet / sec

▲

3" 4" 6" 8" 10" 12" 16" 24" 30" 36" 38" 40"

11.5

19.8

45

78

123

176

313

704

1100

1585

1770

1960

23

39.7

90

156

246

349

551

1250

2200

2910

3530

3915

46.1

79.4

180

312

492

698

1100

2510

4401

5830

7070

7825

115

198

450

780

1230

1740

2750

6270 11002 14570 17670 19560

230

397

900

1560

2460

3490

5510

12530 22005 29140 35350 39120

461

794

1800

3120

4920

6980

11020 25060 44010 58270 70700 78240

691

1190

2700

4680

7370

10470 16520 37600 66015 87410 106050 117500

flow Range.

These sensors are designed to operate at flow

velocities of 0.5 to 30 feet per second (see Table 2, below).

If erratic readings are encountered at low flows, check the

chart to see if flow is below minimum for the pipe size. The

standard shaft and bearings should have a long life at continu-

ous high flow.

TBs-1XX Parts (hot-tap)

All part numbers are the same except those

below

17

Locking Collar

18

Adapter fitting O-ring

19

Adapter, hot tap

20

Valve assembly

(inlcudes Adapter, #20)

oPERaTIon

TX101/201

TX115/215

TBS-0XX

TBS-1XX