Dwyer TBS User Manual

Page 3

InSTallaTIon

Page 2

Page 3

InSTallaTIon

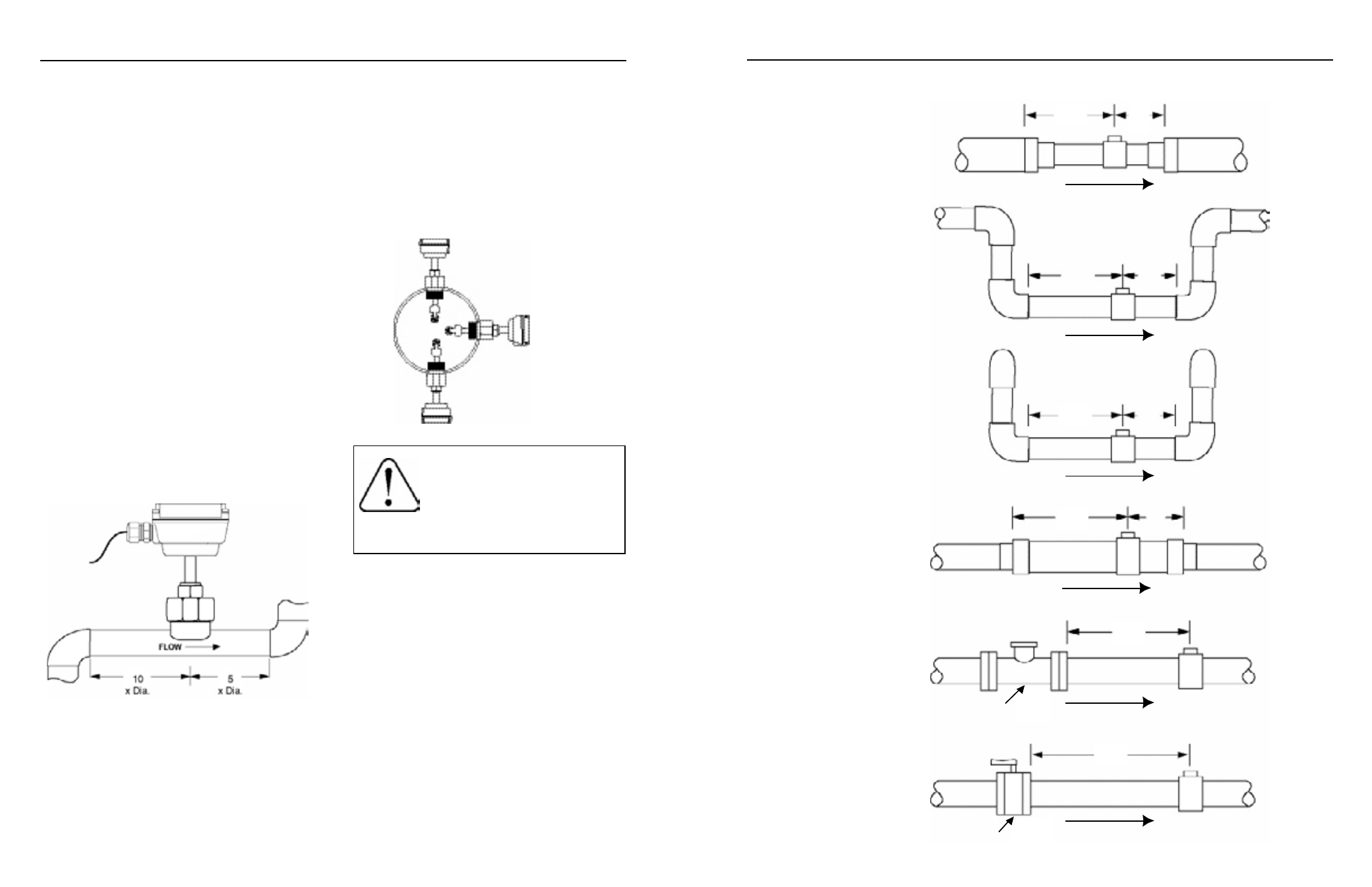

STRaIGHT PIPE RECoMMEnDaTIonS

(X = diameter)

5X

10X

5X

10X

5X

20X

5X

20X

30X

50X

Reduced Pipe

Two Elbows In Plane

Two Elbows, out of Plane

Expanded Pipe

Swirling flow

Propeller Meter

Partially open

Butterfly Valve

Spiral flow

Fair (unacceptable if air is

present)

Fair (unacceptable if fluid

contains sediment)

Best

may experience occasional temporary immersion, as in a

flooded vault, a unit modified for immersion should be speci-

fied (Option -IMM).

An insertion flow sensor measures the velocity of flow at one

point in the pipe; flow rate and total can be inferred from this

one point. Accuracy is decreased by any factor which makes

the flow at the measured point unrepresentative of the entire

flow stream. This includes distorted flow patterns caused

by upstream fittings too close to the sensor. The worst of-

fenders are fittings that increase the flow on one side of the

pipe, such as partially-opened gate or butterfly valves. Fluid

moving in a pipe does not flow at the same velocity. Toward

the center of the pipe, fluid moves faster than at the wall, and

the relationship between the two changes as overall flow rate

increases. This change in the “velocity profile” can result in

non-linearity, which means that the K-factor that is correct for

one flow rate may be incorrect for another. Recommended

depth settings (see page 6) have been carefully chosen to

minimize this source of error, and should be followed carefully,

especially in the smaller pipe sizes.

Piping.

For best results, the TBS sensor should be

installed with at least ten diameters of straight pipe

upstream and five downstream. Certain extreme situations

such as partially-opened valves are particularly difficult and

may require more straight diameters upstream. See Straight

Pipe and Full Pipe recommendations on following pages.

Immersion.

The Series TBS standard sensors are not de-

signed for continuous underwater operation. If your meter

Positioning the Meter.

Horizontal is the preferred instal-

lation orientation, since it improves low-flow performance

slightly and avoids problems with trapped air. Bottom, top,

and vertical pipe installations are all acceptable if required

by the piping layout.

CAUTION: These water meters are

not recommended for installation

downstream of the boiler feedwater

pump where installation fault may

expose the meter to boiler pressure

and temperature. Maximum recom-

mended temperature is 200ºF.

TBS

TBS

TBS

TBS

TBS

TBS