Dwyer TBS User Manual

Page 5

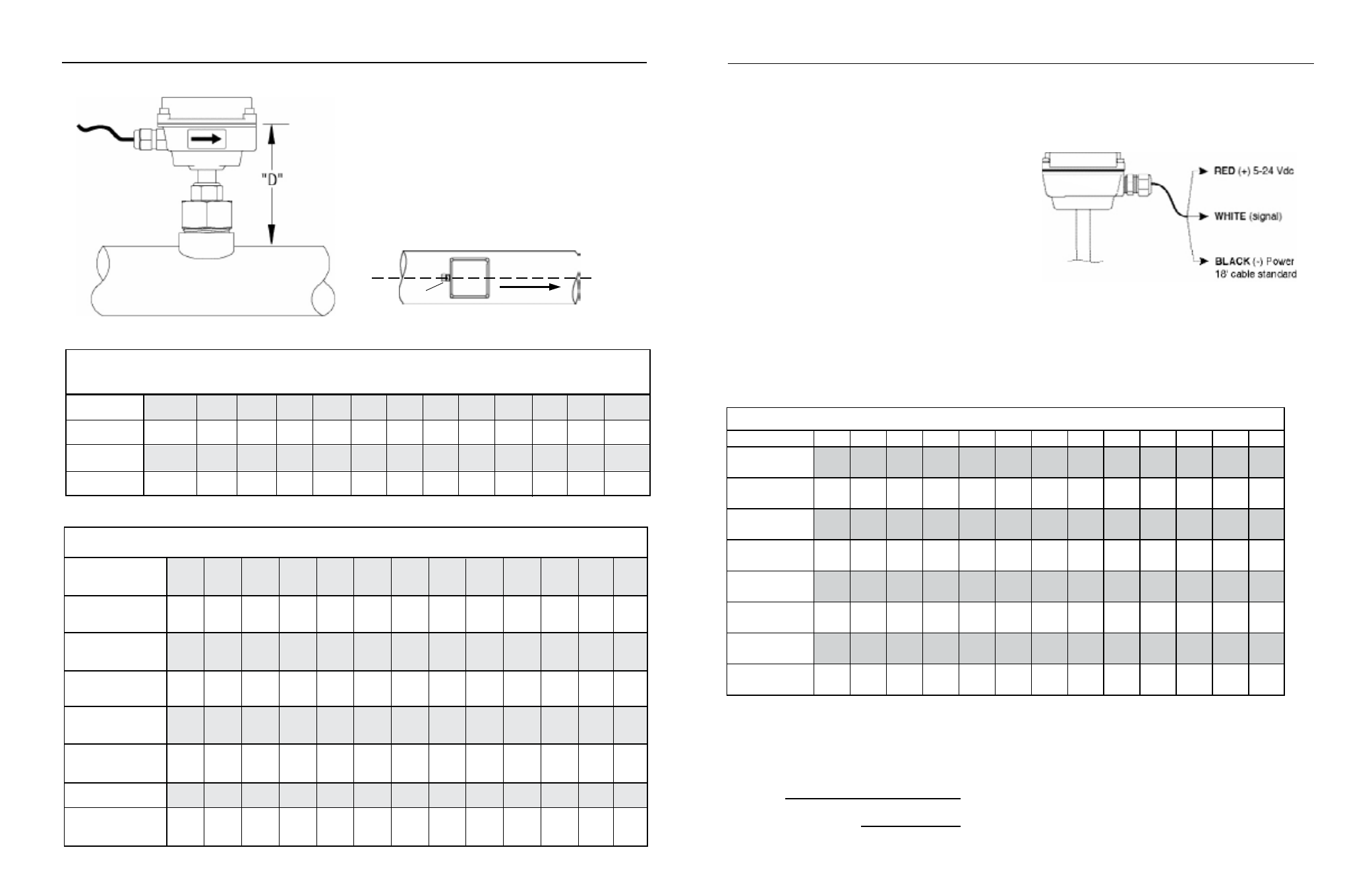

Proper Depth Setting.

It is important for accuracy that

the sensor be inserted to the correct depth into the pipe.

1. In Table 1, find Dimension C for your sensor model

and pipe size. Subtract wall thickness of your pipe

(Table 2) to calculate Dimension D.

2. Measuring from the outside of the pipe to the joint

in the housing, as shown in the diagram on the left,

adjust the sensor to Dimension D and hand-tighten

compression nut.

3. Align the conduit housing with the centerline of the

pipe, as shown. Be sure the arrow on the housing

points in the direction of flow.

4. Check Dimension D one more time.

5. Tighten the compression nut fully.

strain

relief

floW

Page 6

InSTallaTIon

Page 7

TABle 2: PIPe WAll ThICkNess

PVC/Steel

Sch. 40

PVC/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

Copper Tubing

(Type l)

Copper Tubing

(Type K)

Brass Pipe

Duct. Iron

(Class 52)

noMInal PIPE SIzE

3”

4”

6”

8”

10”

12”

14”

16”

18”

20”

24”

30”

36”

0.216 0.237 0.280 0.322 0.365 0.406 0.438 0.500 0.562 0.593 0.687

0.300 0.337 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218

0.120 0.120 0.134 0.148 0.165 0.180 0.188 0.188 0.188 0.218 0.250 0.312 0.312

0.216 0.237 0.280 0.322 0.365 0.375 0.375 0.375 0.375 0.375 0.375 0.375 0.375

0.090 0.110 0.140 0.200 0.250 0.280

0.109 0.134 0.192 0.271 0.338 0.405

0.219 0.250 0.250 0.312 0.365 0.375

0.280 0.290 0.310 0.330 0.350 0.370 0.390 0.400 0.410 0.420 0.440 0.470 0.530

SET-UP

Connection.

Sensors are supplied with 18 ft. of cable.

For sensors with no additional electronics, see diagram for

color coding. For sensors with on-board electronics, see

the manual accompanying the electronics module.

Calibration (“K-factor”).

In order to properly process pulses

from the flow sensor, a number must be entered into the control

to which the sensor is connected. This number, called the K-

factor, is the number of pulses the sensor puts out per unit of

fluid passing through the pipe. It is normally provided for Dwyer

sensors in pulses per gallon (see Table 3 below). These numbers

are based on extensive testing, which has shown close agree-

ment between different TBS sensors in the same installation.

Most K-factor error can be attributed to installation variables,

such as depth setting and fitting configuration.

It is possible to field calibrate a sensor by catching the fluid in a

measured container and comparing with the number of pulses

recorded. (To record individual pulses, set the K-factor on the

control to 1.00.) This is especially desirable if the installation

has less than the recommended length of straight pipe up-

stream of the sensor. For detailed intructions on field calibration,

please contact Dwyer Instruments Inc.

RECoRD YoUR SETTInGS

Once you have the meter set up and operational, it

is important to record your meter setttings and save

them for future reference.

K-Factor

Insertion Depth (Dim. D)

noMInal PIPE SIzE

3”

4”

6”

8”

10”

12”

14”

16”

18”

20”

24”

30”

36”

9.16

9.08

8.99

8.82

8.48

8.14 7.80

7.46

6.78

-

-

-

-

14.16

14.08 13.99 13.82 13.48 13.14 12.80 12.46 11.78 10.42 9.40

9.38

-

16.00

15.80 15.70 15.50 15.10 14.80 14.50 13.80

-

-

-

-

-

19.95

19.85 19.65 19.45 19.15 18.85 18.45 17.75 16.45 15.45 14.35

-

-

TBS-0-S

TBS-0-l

TBS-1-S

TBS-1-l

TABle 1: DImeNsION "C"

nominal Pipe Size

3”

4”

6”

8”

10”

12”

14”

16”

18”

20”

24”

30”

36”

PVC/Steel

Sch. 40

12.067

7.049

2.949

1.690

1.033

0.694

0.575

0.465

0.391

0.326

0.220

-

-

PVC/Steel

Sch. 40

13.506

7.917

3.293

1.845

1.150

0.772

0.631

0.498

0.419

0.354

0.419

-

-

Stainless Steel

(10S)

10.688

6.160

2.663

1.551

0.944

0.642

0.538

0.439

0.364

0.303

0.199

0.127

0.088

Stainless Steel

(40S)

12.067

7.049

2.949

1.690

1.033

0.687

0.565

0.455

0.377

0.313

0.204

0.128

0.088

Copper Tubing

(Type K)

13.441

7.777

3.317

1.865

1.181

0.781

-

-

-

-

-

-

-

Copper Tubing

(Type l)

13.097

7.564

3.193

1.800

1.133

0.744

-

-

-

-

-

-

-

Copper Pipe

12.115

7.156

2.886

1.682

1.033

0.684

-

-

-

-

-

-

-

Duct Iron

(Class 52)

9.974

6.301

2.734

1.528

0.948

0.635

0.487

0.401

0.330

0.269

0.177

0.114

0.079

TABle 3: TX100/200 k-factors (in Pulses/Gallon) for various pipe sizes