Dwyer TBS User Manual

Page 4

Page 4

InSTallaTIon

InSTallaTIon

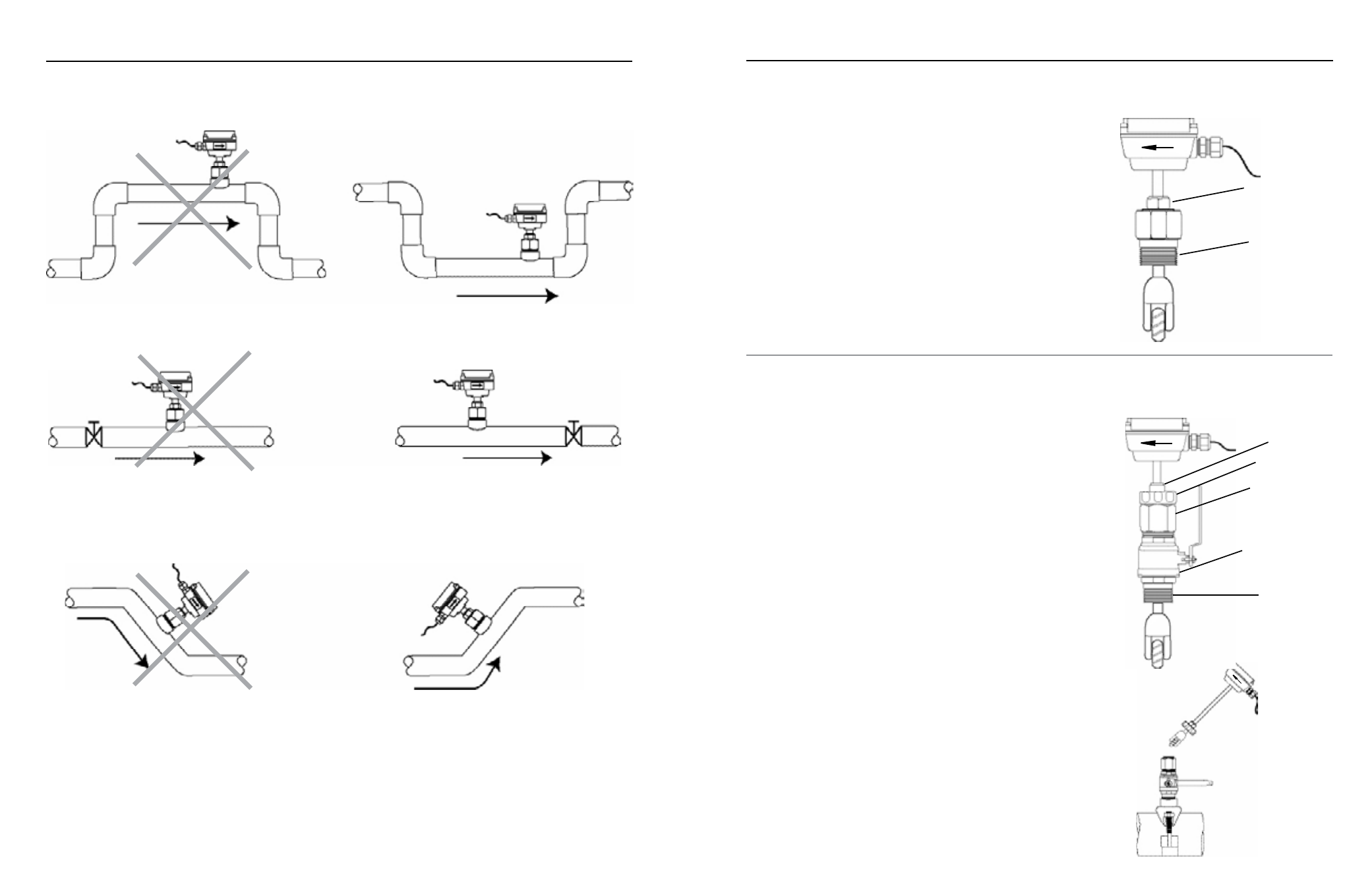

fUll PIPE RECoMMEnDaTIonS

Allows air pockets to form at sensor

Ensures full pipe

Post-valve cavitation can create air pocket

Keeps pipe full at sensor

Air can be trapped

Allows air to bleed off

Page 5

Better Installation

Possible Problem

Better Installation

Possible Problem

Better Installation

Possible Problem

TBS-0XX InSTallaTIon

fitting Installation.

TBS-0XX sensors come with a 1-1/2” male NPT pipe

thread adapter fitting. Any fitting that provides the matching NPT female

thread may be used. (For comparable saddle fitting please see Series

SDF.) Installation procedure compensates for fitting height differences.

Cut a minimum 1-3/4” hole in the pipe. If possible, measure the wall

thickness and write it down for use in depth setting. Then install the

threaded fitting (saddle, weldolet, etc.) on the pipe.

Meter Installation.

Loosen the compression nut so that the adapter slides

freely. Pull the meter fully upward and finger-tighten the compression

nut. Using a thread sealant, install the adapter in the pipe fitting. Do

not overtighten. Loosen the compression nut and lower the meter to

the appropriate depth setting (see diagram and instructions that follow).

Caution: Do not allow the meter to fall into the pipe uncontrolled, as this

may damage the meter. Be sure flow is in the direction of the arrow on

the housing. Tighten compression nut fully.

TBS-1XX InSTallaTIon

‘Hot-tap’ meters are designed to be installed and serviced without

depressurizing the pipe.

fitting Installation.

The hot-tap sensors have a 2” male NPT thread for

compatibility with the 2” isolation valve. Any fitting that provides matching

NPT female thread may be used. The installation procedure compensates

for differences in fitting height.

If initial installation is performed on an unpressurized pipe, cut a

minimum 1-3/4” hole in the pipe. If possible, measure the wall thickness

and write it down for use in depth setting. Then install the threaded fitting

(saddle, weldolet, etc.) on the pipe. (Such as the Series SDF.)

If it is necessary to do the initial installation under pressure, any standard

hot-tap drilling machine with 2” NPT adapter, such as a Transmate or a

Mueller, can be used. Ordinarily, it is not necessary to use an installation

tool, since the small-diameter tube can be controlled by hand but should

be used for higher pressures.

Meter Installation.

Remove the sensor unit from the valve assembly.

Using a thread sealant, install the valve assembly on the pipe fitting. If

the initial installation is a pressure (“hot-tap"), remove the 1-1/2” x 2”

adapter bushing at the back of the valve. Thread the tapping machine

on, open the valve, and tap using a minimum of 1-3/4” or maximum

1-7/8” cutter. After retracting the machine and closing the valve, reinstall

the flow sensor. When the sensor is secure, open the valve and adjust

depth setting (see diagram and instructions that follow). Be sure flow is

in the direction of the arrow on the housing. Tighten locking collar and

compression nut fully.

Compression nut

Adapter fitting

with

standard 1-1/2"

NPT threads

Compression nut

2” adapter removes

to mount hot-tap

machine

Full-port 2” ball

valve allows sensor

removal

Standard 2”

NPT threads

TBS-1XX Sensor

Removal

Locking collar

TBS-0XX