Pre-installation, Installation, Continued) – Blue Angel Pumps SBS100 User Manual

Page 3

3

Pre-Installation

(Continued)

PACKAGE SYSTEMS

There are four jet pump/tank assem-

blies sold as packages (Chart 1).

WELLS

A new well should be pumped clear of

sand before installing the pump. Sand

will damage the pumping parts and

seal. The drawdown level of the well

should not exceed the maximum rated

depth for the pump. The capacity of

the pump will be reduced and a loss of

prime may occur.

Installation

LOCATION

Select a location as close to the water

supply as possible. Be sure to comply

with any state or local codes regarding

the placement of the pump. The

equipment must be protected from the

elements. A basement or heated pump

house is a good location. Make sure

the pump has proper ventilation. The

temperature surrounding the pump is

not to exceed 100° F (40°C) or nuisance

tripping of the motor overload may

occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or flexible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe).

The pipe must be clean and free of rust

or scale. Use a pipe joint compound on

the male threads of the metal pipe.

Teflon

®

tape should be used with plas-

tic threads. All connections must be air

tight to insure normal operation.

Slope all inlet piping upwards towards

the pump to prevent trapping air.

Unions or hose couplings can be

installed near pump to facilitate

removal for servicing or storage. A

rubber hose installed between the

water system and the house piping will

reduce the noise transmitted to the

house.

PIPE SIZES

Long horizontal pipe runs and an

abundance of fittings and couplers

decrease water pressure due to friction

loss. See Chart 2 to determine the

proper pipe size.

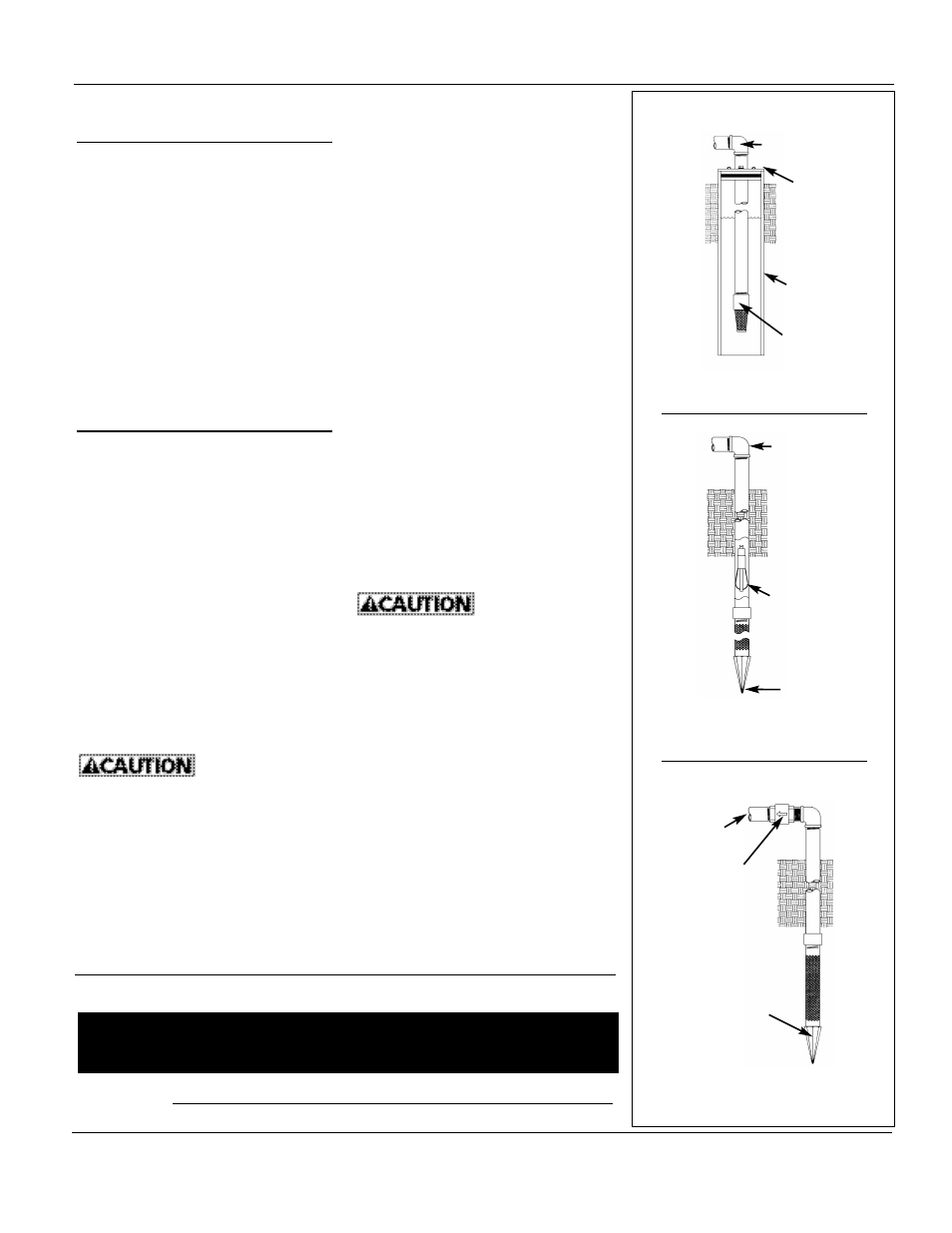

SHALLOW WELL INSTALLATION

A shallow well pump can be used when

the pump is located within 25 feet ver-

tically of the water level. Shallow well

pumps have only one pipe between the

pump and the water supply (Figure 3).

DRILLED WELL (FIGURE 12)

1. Install a foot valve on the first section

of pipe (Figure 3, Illustration A).

2. Lower the pipe into the well.

3. Add pipe until the foot valve is 5

feet below the lowest anticipated

water level.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

4. After proper depth is reached,

install a well seal or pitless adapter

to support pipe and prevent surface

water and other contaminants from

entering well.

5. Slope the horizontal pipe upward

toward the pump to eliminate trap-

ping air. Sloping the pipe will also

aid in priming the pump.

DRIVEN WELL (FIGURE 12)

1. Drive the point several feet below

the water table.

NOTE: A packer type foot valve can be

installed in the well (Figure 3, Illustra-

tion B). This type of foot valve allows

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

CHART 2 - PIPE SIZING

Illustration B

Illustration C

Packer

Type

Foot

Valve

Drive

Point

To Pump

Incline

Check

Valve

Drive

Point

To Pump

Figure 3

To Pump

Illustration A

Well

Seal

Well

Casing

Foot

Valve

Horizontal Distance

Pump

Pump

(Feet)

Model

Opening

0-25

26-100

100-300

Shallow Well Inlet

1

1

/

4

”

1

1

/

2

”

2”

Outlet

3/4”

1”

1

1

/

4

”

www.blueangelpumps.com