Installation – Badger Meter QuikSert User Manual

Page 8

INSTALLATION

Before installation, the flow meter should be checked internally for foreign material and to be sure that the rotor spins freely .

Gas lines should also be cleared of all debris . The flow meter must be installed with the flow indication arrow, etched on the

exterior of the meter body, pointing in the correct direction of flow . The preferred mounting orientation is to have the meter

installed in horizontal piping, with the pickup facing upward . However, the meter will function in any position .

While the flow meter body and magnetic pickup are sold as separate items, in most instances they are ordered at the same

time and come assembled from the factory . If the magnetic pickup was not ordered with the meter body or replacement of

the magnetic pickup becomes necessary, all that is needed to install it is to thread the pickup into the pickup port until it is

bottomed out . Finger tightening is all that is required for proper installation .

The gas that is to be measured must be free from any large particles that may obstruct the rotor from turning . If particles are

present, a filter of at least 60 mesh (0 .0092 clearance) should be installed upstream before operation of the flow meter .

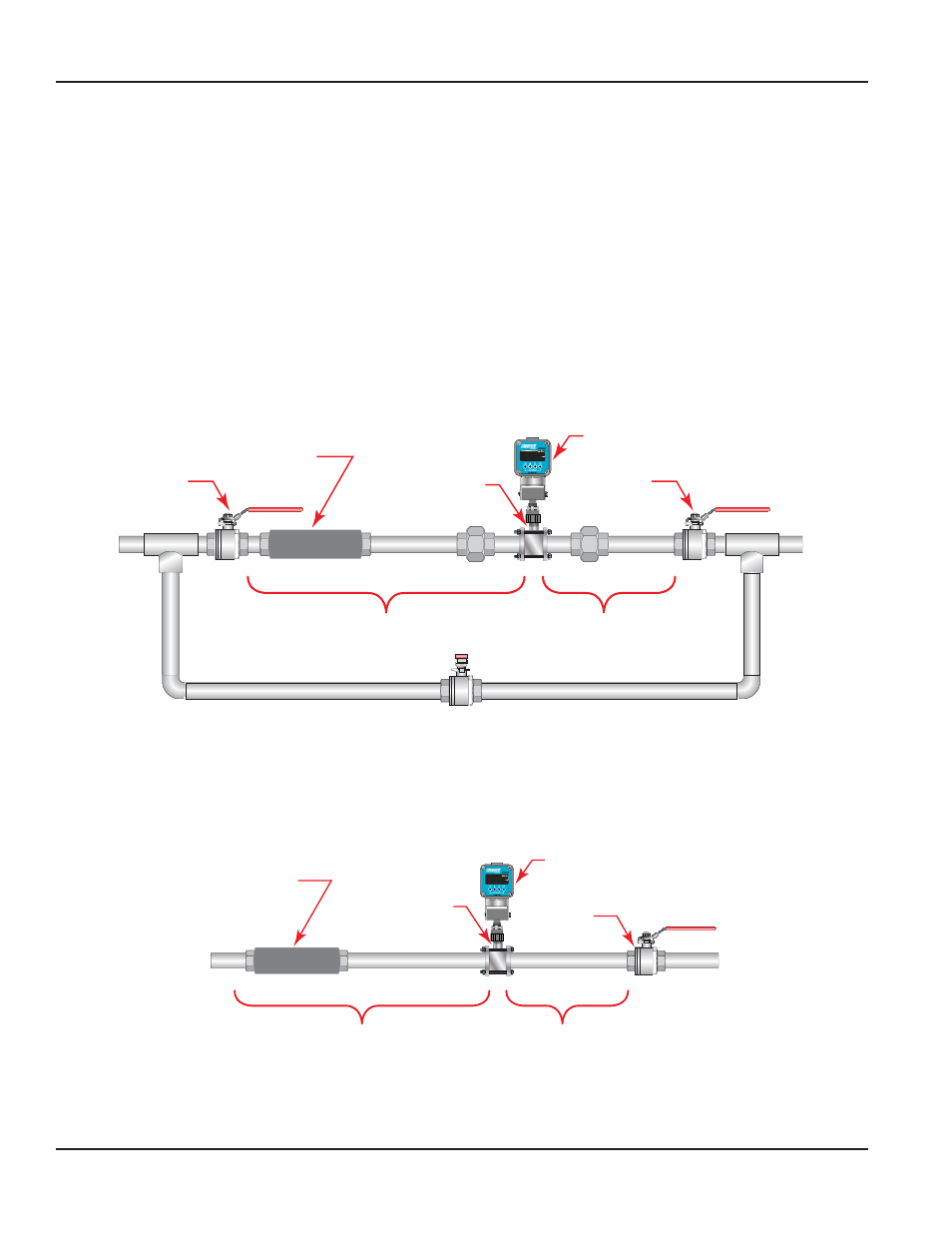

The preferred plumbing setup is one containing a bypass line (see

) that allows for meter inspection and repair

without interrupting flow . If a bypass line is not used, it is important that all control valves be located downstream of the flow

meter (see

) .

Flow Straightner

(Optional)

Isolation

Valve

Isolation

Valve

QuikSert Turbine

Flow Meter

Display

Bypass Line

5 Pipe Diameters

Minimum

10 Pipe Diameters

Minimum

2

1

Figure 4: Bypass line installation

It is recommended that a minimum length, equal to ten (10) pipe diameters of straight pipe, be installed on the upstream side

and five (5) diameters on the downstream side of the flow meter . Otherwise meter accuracy may be affected . Piping should be

the same size as the flange size . If adequate straight runs of pipe are not available or if erratic flow readings are experienced,

place a bundled-tube flow straightener upstream of the flow meter installation .

5 Pipe Diameters

Minimum

10 Pipe Diameters

Minimum

Isolation

Valve

Display

Flow Straightner

(Optional)

QuikSert Turbine

Flow Meter

2

1

Figure 5: Installation without bypass line

Turbine Flow Meter, B142 Gas QuikSert

Page 8

June 2014