K factor calculation in standard cubic feet, Dynamic systems, Flow computer – Badger Meter QuikSert User Manual

Page 17: System pressure in psia (14 .73 + gage pressure) p, Standard pressure in psia t

K factor Calculation in Standard Cubic Feet

If the running conditions are held constant, the K factor adjustment for converting actual cubic feet to standard cubic feet will

also remain constant . In applications where a direct readout in standard cubic feet is desirable the following formula can be

used to determine the K factor for any given set of operating conditions:

Adjusted K factor =

P x T

Factory K factor x P x T

s

a

a

r

Example 2

A 2 inch B142 gas turbine meter has a factory K factor of 190 pulses per actual cubic foot and is installed in an application

operating at 100 psig at 80° F . Calculate the adjusted K factor that will allow the downstream electronics to display flow in

standard cubic feet .

Where:

Factory K factor = the K factor from the factory supplied in pulses per acf (actual ft

3

) .

P

a

= system pressure in psia (14 .73 + gage pressure)

P

s

= standard pressure in psia

T

a

= system temperature in °R (system temperature in ° F + 459 .67)

T

s

= standard temperature in °R (standard temperature in ° F + 459 .67) = 519 .76° R

Adjusted K factor =

190 x14.73 x (80 + 459.67)

(100 + 14.73) x (60 + 459.67)

=

190 x 14.73 x 539.67

114.73 x 519.67

=

1,510,375

59,622

= 25.333

OTEE:

N

If a Blancett readout such as the B3000 is being used, entering the operating pressure (Op Pres) and operating

temperature (Op Temp) will allow the readout to calculate the adjusted K factor automatically, eliminating the need

to do manual conversions .

In this example, as long as the pressure and temperature stay at 100 psig and 80° F, a K factor of 25 .33 will allow the

downstream electronics to display rate and total in scfm .

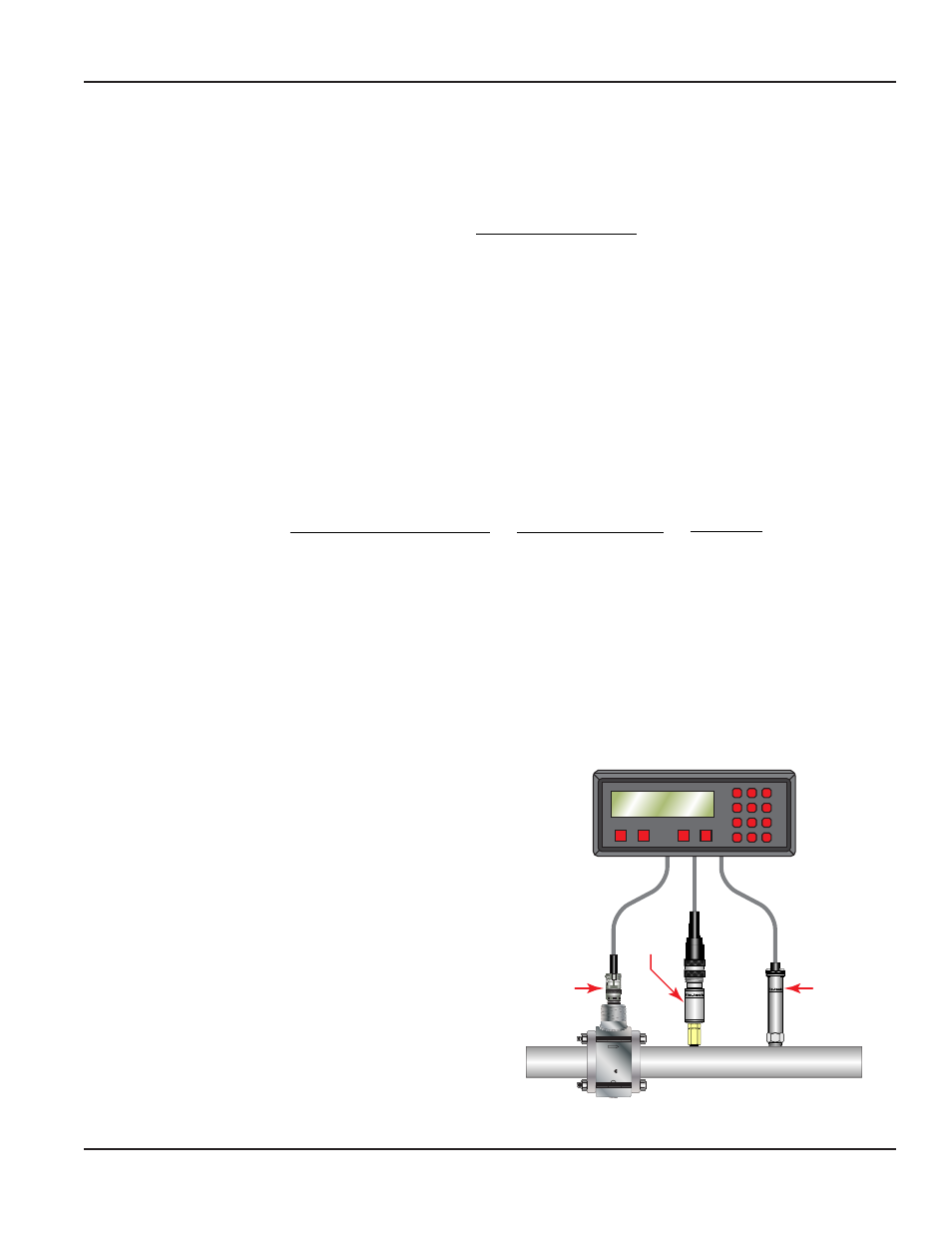

Dynamic Systems

In systems where pressure and/or temperature vary

constantly, the alternative to extracting scf from acf data is to

use of a flow computer and discrete pressure and temperature

transducers .

SENSOR S.N.: 64

PRESSURE SENSOR:

OUTPUT: 4 - 20 mA

HEDLAND

by

RT

D

HEDLAND

by

®

SENSOR S.N.: 64802

CAL. POINT: 154.9 °F: 12.

RANGE: -40 °F - 350 °F

OUTPUT: 4 - 20 mA

RACINE, WI USA

R

215035

ELECTRICAL SAFETY

E112860

Ci = 0µF Li = 1.65H

W/ B111113 INSTALLED

Vmax = 10V Imax = 3mA

S/N XXXXXXXX

2220 PSI

15.3 MPa

MODEL XXX-XXX

CL I DIV 1 GP C,D

SINGLE SEAL

350°F

MAX. WP/T

CL

ASSIFIED

®

C US

ADVANCE

BACKUP

CANCLE

DEC. PT.

1

2

4

4

5

6

7

8

9

ENT

0

CLR

A

B

C

D

Flow

Sensor

Pressure

Sensor

Temperature

Sensor

Flow Computer

Figure 10 Typical flow computer inputs

User Manual

Page 17

June 2014