Replacing turbine cartridges, Replacement procedure, Gas compensation considerations – Badger Meter QuikSert User Manual

Page 15: Absolute pressure and temperature

REPLACING TURBINE CARTRIDGES

If a turbine is damaged and it becomes necessary to service the meter, repairs are easily accomplished in the field using

slide-in replacement cartridges .

Cartridge replacement kits come complete with the turbine cartridge and two retaining rings .

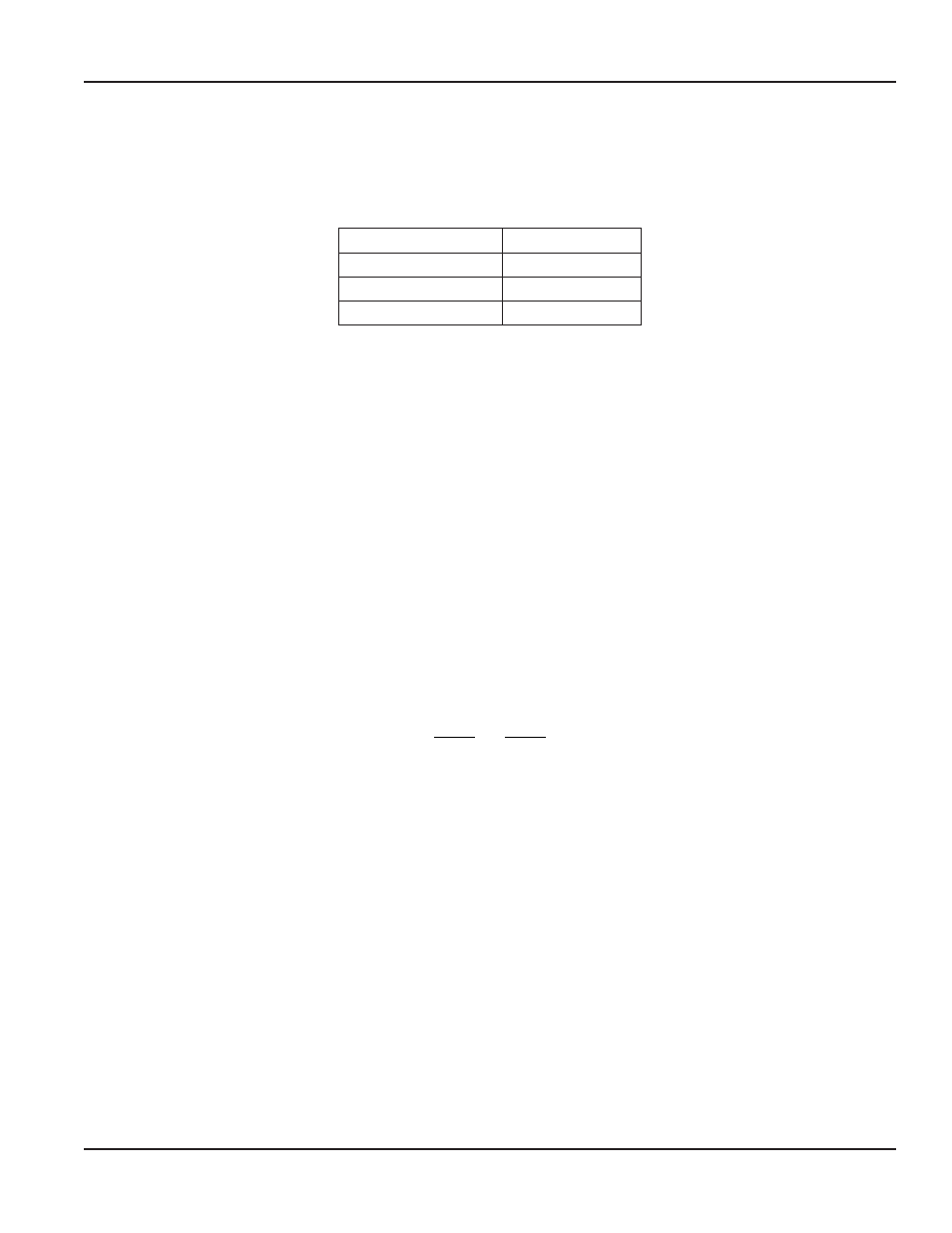

Size

Part Number

Low Flow Cartridge

B142-20L-Kit

Mid Flow Cartridge

B142-20M-Kit

High Flow Cartridge

B142-20H-Kit

Replacement Procedure

1 . Using a knife edge or a small flat bladed screwdriver, remove both retaining rings . With the retaining rings absent, the old

turbine cartridge should be easily removed .

2 . Clean any foreign materials from the bore of the meter body that may restrict sliding the new turbine cartridge into place .

3 . Replace the downstream retaining ring with one of the new retaining rings supplied in the kit .

4 . With the meter body on a flat surface and the downstream end facing down, the direction arrow on the outside of the

meter body should also be facing down . Place the turbine cartridge at the opening of the meter body with the arrow on

the turbine cartridge facing the same direction as the arrow on the meter body .

5 . Rotate the turbine cartridge so that the gap in the cartridge lines up with the magnetic pickup, then squeeze the cartridge

to reduce the gap until the cartridge slides into the meter body .

OTEE:

N

In a properly aligned cartridge the pressure port at the bottom of the meter body will also line up with the round

hole at the bottom of the turbine cartridge .

6 . Install the inlet retaining ring .

Gas Compensation Considerations

Gaseous fluids measured by the B142 gas turbine meter are compressible and are also affected by temperature changes, as

illustrated by the ideal gas law equation:

=

P V

1 1

T

1

P V

2 2

T

2

This equation allows the calculation of gas volumes when the pressure and/or temperature values vary from standard

conditions . Standard conditions are generally assumed to be 0 psig and 60° F .

Because pressure and temperature have a large impact on the mass of gas moving through the flow meter, both values must

be entered into the receiving electronics for accurate gas readings to occur .

Absolute Pressure and Temperature

The ideal gas law equation shows that the volume of gas is determined by the specific pressure and temperature applied to

the gas under running conditions .

User Manual

Page 15

June 2014