Alicat VC Series Volumetric Flow Controller User Manual

Page 39

39

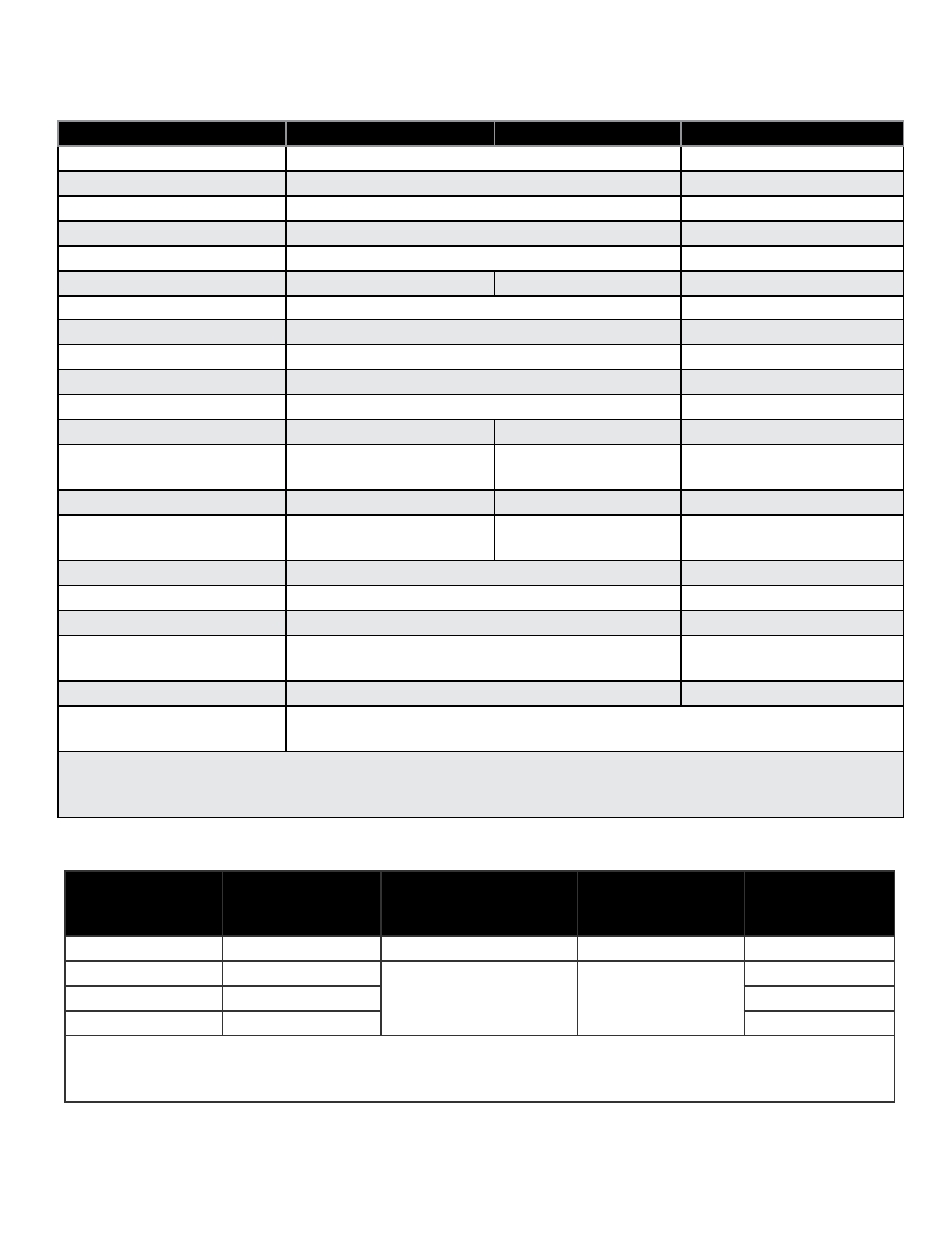

Specification

Mass Controller

Volumetric Controller

Description

Accuracy

± (0.8% of Reading + 0.2% of Full Scale)

At calibration conditions after tare

High Accuracy Option

± (0.4% of Reading + 0.2% of Full Scale)

At calibration conditions after tare

Repeatability

± 0.2%

Full Scale

Operating Range

1% to 100% Full Scale

Measure

Typical Response Time

100

Milliseconds (Adjustable)

Standard Conditions (STP)

25ºC & 14.696PSIA

Not Applicable

Mass Reference Conditions

Operating Temperature

−10 to +50

ºCelsius

Zero Shift

0.02%

Full Scale / ºCelsius / Atm

Span Shift

0.02%

Full Scale / ºCelsius / Atm

Humidity Range

0 to 100%

Non–Condensing

Controllable Flow Rate

102.4%

Full Scale

Maximum Pressure

145

145

1

PSIG

Input /Output Signal Digital Mass, Volume, Pressure

& Temperature

Volumetric Flow

RS-232 Serial

Input / Output Signal Analog

Mass Flow

Volumetric Flow

0-5Vdc

Optional Input / Output

Signal Secondary Analog

Mass, Volume, Pressure

or Temperature

Volumetric Flow

0-5 Vdc or 0-10Vdc or

4-20mA

Electrical Connections

8 Pin

Mini-DIN

Supply Voltage

24 to 30 Vdc

Supply Current

0.750Amp

Mounting Attitude Sensitivity Control response somewhat sensitive to inverted

operation.

Warm-up Time

< 1

Second

Wetted Materials

2

303 & 302 Stainless Steel, Viton®, Silicone RTV (Rubber), Glass Reinforced

Nylon, Aluminum, 410 & 416 Stainless Steel, Nickel, Silcon, Glass.

1. Volumetric meters only: Operating pressure limitations determined by Reynolds number thresholds. For

operating pressures >10PSIG, please contact the manufacturer for more details.

2. If your application demands a different material, please contact the manufacturer for available options.

Technical Data for High Flow Mass & Volumetric Flow Controllers

0 to 250SLPM Full Scale through 0 to 1500SLPM Full Scale

Mechanical Specifications

Full Scale Flow

Mass Controller

Full Scale Flow

Volumetric

Controller

Mechanical

Dimensions

Process

Connections

1

Pressure Drop

2

(PSID)

250SLPM

250LPM

5.5”H x 7.9”W x 2.3”D

1/2” NPT Female

4.6

500SLPM

500LPM

5.5”H x 7.4”W x 2.3”D

3/4” NPT Female

6.5

1000SLPM

1000LPM

14.0

1500SLPM

1500LPM

17.0

1. Compatible with Beswick®, Swagelok® tube, Parker®, face seal, push connect and compression

adapter fittings.

2. Venting to atmosphere. Lower Pressure Drops Available, Please contact the manufacturer.

Dimensional Drawings: page 41, 42