Alicat VC Series Volumetric Flow Controller User Manual

Page 17

17

Select

Main

>

LCD Contrast

(10) .

10

PVM DBand

(0.5

%

FS

)

PRESS Avg

(008) . . . 008

FLOW Avg

(100) . . . . 100

UP DOWN Misc

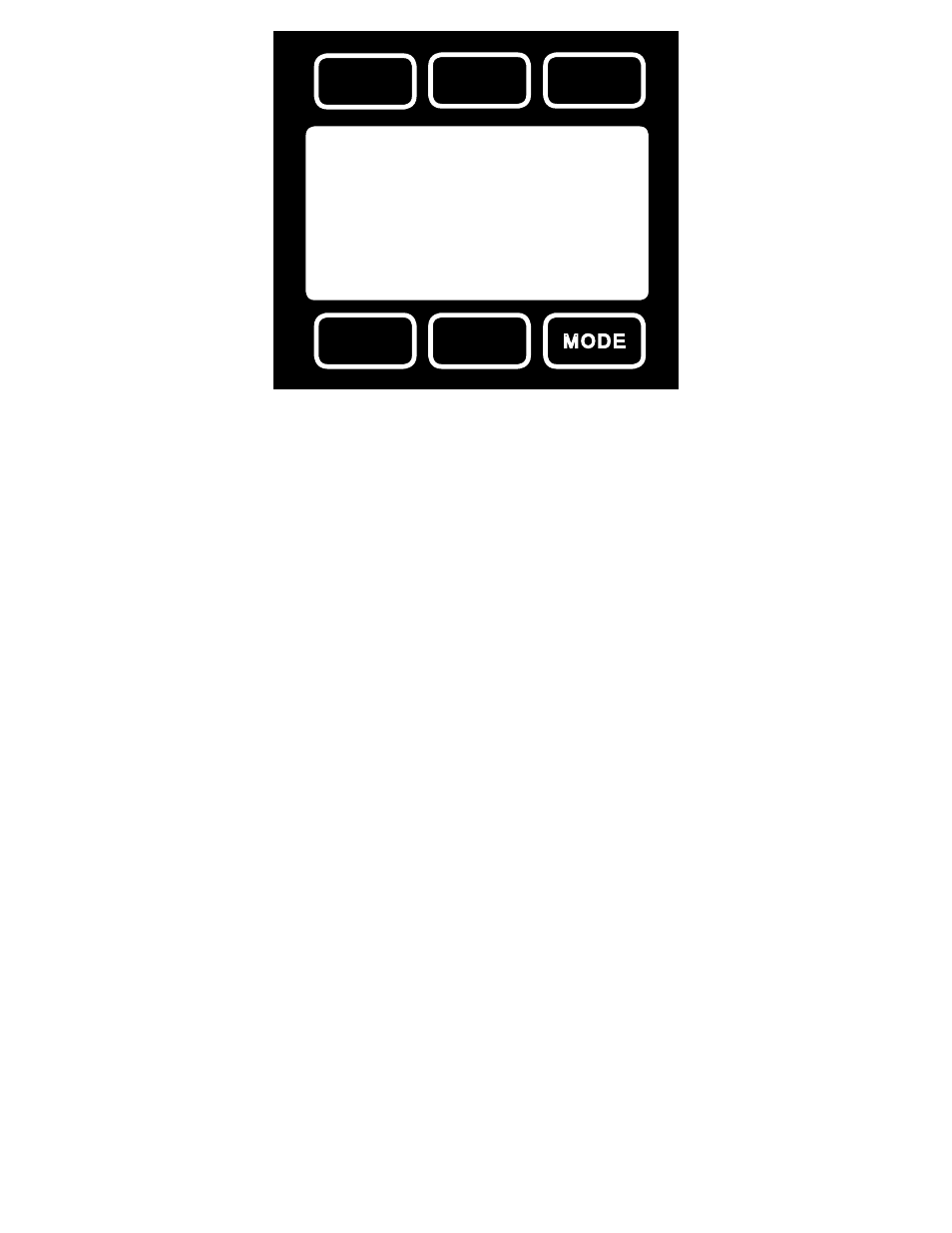

Figure 12. Miscellaneous Display

LCD Contrast: The Liquid Crystal Display Contrast can be adjusted between 0 and 30 with zero being

the lightest contrast and 30 being the darkest contrast. To change the contrast, press the “Select”

button in the upper left hand corner of the display until the cursor arrow is in front of the words “LCD

Contrast (X)”. Then using the UP and DOWN buttons at the bottom of the display, change the contrast

value as desired. The change is immediate and the effect can be monitored as the value is changed.

Display Zero Deadband: Zero deadband refers to a value below which the display simply jumps to

zero. This deadband is often desired to prevent electrical noise from showing up on the display as minor

flows or pressures that do not actually exist, especially in high noise (electrical) environments. This

display deadband does not affect the analog or digital signal outputs — there is no zero deadband on the

output signals. The display zero deadband can be adjusted between 0 and 3.2% of the Full Scale (FS)

of the sensor. PVM refers to Pressure, Volumetric Flow, and Mass Flow, the three parameters to which

the deadband applies. To adjust the display zero deadband, press the “Select” button in the upper left

hand corner of the display until the cursor arrow is in front of the words “PVM DBand (X %F.S.)”. Then

using the UP and DOWN buttons at the bottom of the display, change the display zero deadband value

as desired.

Pressure Averaging: It is sometimes advantageous to apply an averaging factor to the pressure output

(and display) to make it easier to read and interpret rapidly fluctuating pressures. Pressure averaging

can be adjusted between 1 (no averaging) and 256 (maximum averaging). This is a geometric running

average where the number between 1 and 256 can be considered very roughly equivalent to the

response time constant in milliseconds. This can be very effective at “smoothing” high frequency process

oscillations such as those caused by diaphragm pumps. To adjust the pressure averaging, press the

“Select” button in the upper left hand corner of the display until the cursor arrow is in front of the words

“PRESS Avg (XXX)”. Then using the UP and DOWN buttons at the bottom of the display, change the

pressure averaging value as desired.

Flow Averaging: It is sometimes advantageous to apply an averaging factor to the flow output (and

display) to make it easier to read and interpret rapidly fluctuating flows. Flow averaging can be adjusted

between 1 (no averaging) and 256 (maximum averaging). This is a geometric running average where

the number between 1 and 256 can be considered very roughly equivalent to the response time constant

in milliseconds. This can be very effective at “smoothing” high frequency process oscillations such as

those caused by diaphragm pumps. To adjust the flow averaging, press the “Select” button in the upper

left hand corner of the display until the cursor arrow is in front of the words “FLOW Avg (XXX)”. Then

using the UP and DOWN buttons at the bottom of the display, change the flow averaging value as

desired.