Ecochill chiller, Ethylene glycol solutions – Airedale EcoChill 6kW - 46kW User Manual

Page 30

30

EcoChill

Chiller

Technical Manual 7300221 V1.1.0_02/2013

9.

ETHYLENE GLYCOL

SOLUTIONS

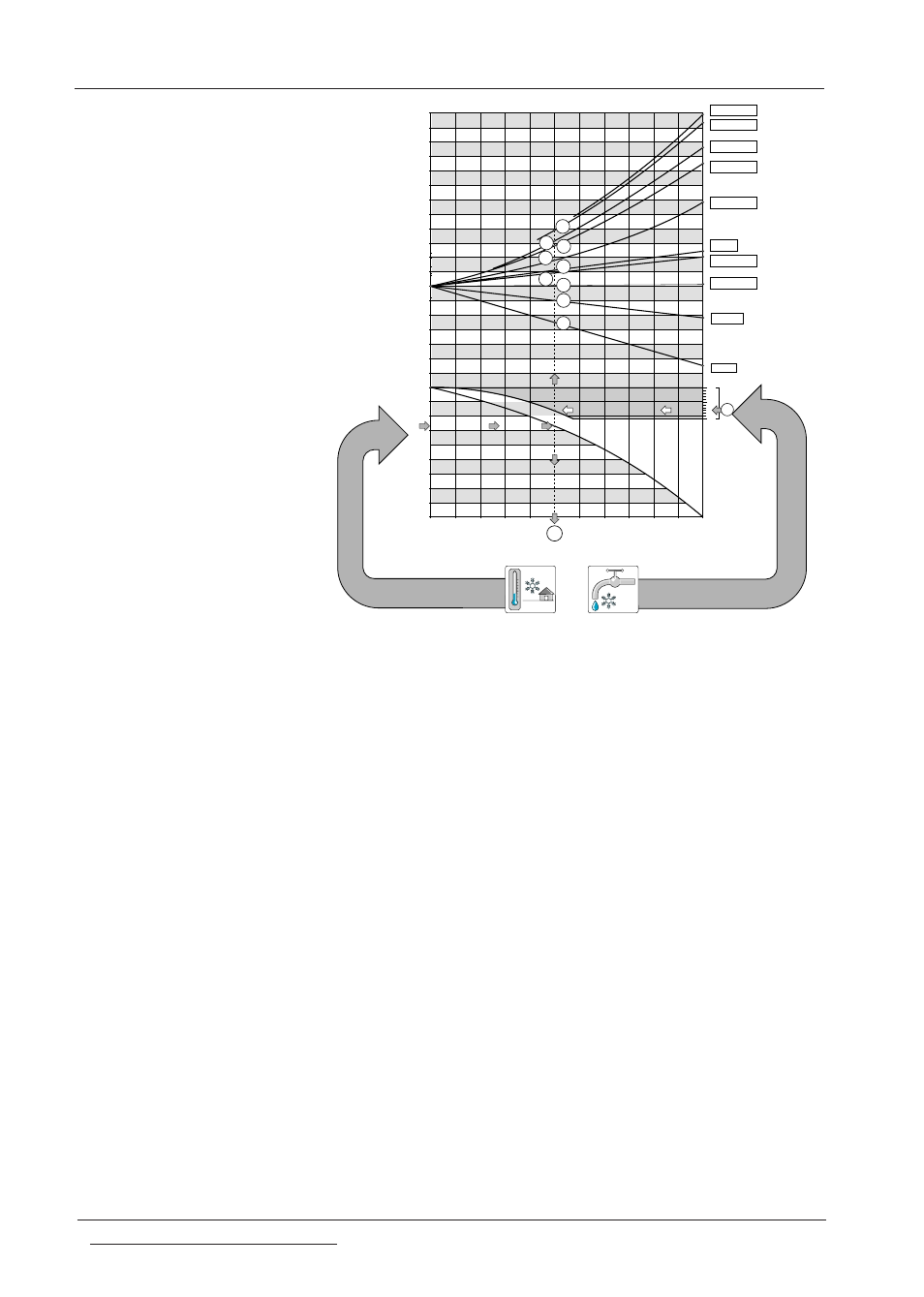

The correction factors of cooling power

and input power take into account the

presence of glycol and diverse evaporation

temperatures.

The pressure drop correction factor

considers the different flow rate resulting

from the application of the water flow rate

correction factor.

The water flow rate correction factor is

calculated to keep the same ∆t that would

be present with the absence of glycol.

NOTE

On the following page an example is

given to help graph reading.

Using the diagram below it is possible

to determine the percentage of glycol

required; this percentage can be

calculated by taking of the following

factors into consideration one:

Depending on which fluid is

considered (water or air), the graph

is interpreted by the right or left side

at the crossing point on the curves

with the external temperature line

or the water produced line. A point

from which the vertical line will pass

is obtained and this will distinguish

both glycol percentage and relative

correction coefficients.

HOW TO INTERPRET GLYCOL

CURVES

The curves shown in the diagram

summarise a significant number of

data, each of which is represented by

a specific curve. In order to use these

curves correctly it is first necessary to

make some initial reflections.

If you wish to calculate the percentage

of glycol on the basis of the external

air temperature, enter from the left

axis and on reaching the curve draw

a vertical line, which in turn will

intercept all the other curves; the

points obtained from the upper curves

represent the coefficients for the

correction of the cooling capacity and

input power, the flow rates and the

pressure drops (remember that these

coefficients must be multiplied by the

nominal value of the size in question);

while the glycol percentage value

recommended to produce desired

water temperature is on the lower

axis.

If you wish to calculate the percentage

of glycol on the basis of the

temperature of the water produced,

enter from the right axis and on

reaching the curve draw a vertical

line, which in turn will intercept all

the other curves; the points obtained

from the upper curves represent the

coefficients for the correction of the

cooling capacity and input power, the

flow rates and the pressure drops

(remember that these coefficients

must be multiplied by the nominal

value of the size in question); while

the lower axis recommends the

glycol percentage value necessary

to produce water at the desired

temperature.

Initial rates for “EXTERNAL AIR

TEMPERATURE” and “Water

Temperature °C”, are not directly

related, therefore it is not possible to

refer to the curve of one of these rates

to obtain corresponding point on the

curve of the other rate.

KEY:

FcGPf

Corrective factors for cooling capacity

FcGPa

Corrective factors of the input power

FcGDpF (a) Correction factors for pressure drop (evaporator) (av. temp. = -3.5 °C)

FcGDpF (b) Correction factors for pressure drops (av. temp. = 0.5 °C)

FcGDpF (c) Correction factors for pressure drops (av. temp. = 5.5 °C)

FcGDpF (d) Correction factors for pressure drops (av. temp. = 9.5 °C)

FcGDpF (e) Correction factors for pressure drops (av. temp. = 47.5 °C)

FcGQF

Correction factor of flow rates (evap.) (av. temp. = 9.5 °C)

FcGQC

Correction factors of flow rates (condenser) (av. temp. = 47.5 °C)

NOTE

Although the graph arrives at external air temperatures of -40°C, unit opera-

tional limits must be considered.

2.20

2.10

2.00

1.90

1.80

1.70

1.60

1.50

1.40

1.30

1.20

1.10

1.00

0.99

0.98

0.97

0.96

0.95

0.94

5

0

-5

-10

-15

-20

-25

-30

-35

-40

0

5

10

15

20

25

30

35

40

45

50

55

-6

0

5

0.975

0.990

1.000

1.090

1.110

1.180

1.280

1.310

1.390

-3

FcGPf

FcGPa

FcGPf (PdC)

FcGQ (PdC)

FcGDpF (e)

FcGDpF (d)

FcGDpF (c)

FcGDpF (b)

FcGDpF (a)

FcGQF

W

ater T

emperature °C

External air temperature

Glicol%