Ecochill chiller, Water filter, Storage tank (only in versions a) – Airedale EcoChill 6kW - 46kW User Manual

Page 12: Desuperheater, Air vent, Expansion vessel, Cooling only (°), High pressure pressure switch (hp)

12

EcoChill

Chiller

Technical Manual 7300221 V1.1.0_02/2013

2.2.

HYDRAULIC CIRCUIT

Circulation pump (circulator)

P - N - A - Q versions.

Flow meter

Available in sizes "ECL 020 - 025 -

030 - 040 versions A with storage

tank".

Positioned upstream from evaporator,

it has the task of monitoring water flow.

On low flow the unit is disabled.

Differential pressure switch

Available in sizes:

"ECL 050 - 070 - 080 - 090 - 100 - 150 -

200 versions A with storage tank".

"ECL 020 - 025 - 030 - 040 - 050 - 070

- 080 - 090 - 100 - 150 - 200 standard

and P with pump"

Positioned between inlet and

outlet of evaporator. It has the task

of controlling that there is water

circulation, if this is not the case it

blocks the unit.

Water filter

This allows to block and eliminate any

impurities present in the hydraulic

circuits. It contains a filtering mesh

with holes that do not exceed one

millimetre.

It is indispensable in order to

prevent serious damage to the plate

exchanger.

Storage tank

(only in versions A)

It is required to reduce the number of

starts of the compressor and to even

the temperature of water to be sent to

the utilities.

- For ECL 020 - 025 25 l.

- For ECL 030 - 040 35 l.

- For ECL 050 - 070 - 080 - 090 75 l

- For ECL 100 - 250 - 200 100 l

Desuperheater

Plate type (AISI 316) desuperheater

, insulated externally with closed cell

material to reduce heat loss. ONLY

AVAILABLE FOR SIZES FROM 050

TO 200.

Air vent

(only for versions with hydronic unit or

with a pump)

− Manual type, discharges any air

pockets present. It has a shut off

valve to facilitate any replacement.

Expansion vessel

(only in versions complete with

storage tank or pump)

membrane type with nitrogen pre-

load.

Hydraulic circuit safety valve

(only in versions with hydronic unit or

pump).

Calibrated at 6 BAR and with

conveyable discharge, intervenes by

discharging the excess pressure in

the case of high system pressure

2.3. CONTROL AND SAFETY COM-

PONENTS

Low pressure pressure switch (LP)

Cooling Only (°)

With fixed calibration, placed on

low pressure side of cooling circuit,

inhibits functioning of compressor

if abnormal low suction pressure

occurs.

High pressure pressure switch

(HP)

− Cooling Only (°)

− Heat pump (H)

With fixed calibration, placed on

high pressure side of cooling circuit,

inhibits functioning of compressor if

abnormal work pressure occurs.

Low pressure transducer (TBP)

Heat pump (H)

Placed on low pressure side of

cooling circuit, it communicates the

suction pressure to the control board,

generating a pre-alarm if abnormal

pressure occurs.High pressure

transducer (TAP)

cooling only (D)

Heat pump (H) (HD)

Placed on high pressure side of

cooling circuit, it communicates the

discharge pressure to the control

board, generating a pre-alarm if

abnormal high pressure occurs.

ELECTRIC COMPONENTS

Electric Control Board

Contains the power section and the

management of controls and safety

devices. It is in compliance with

the IEC 60204-1 Standard and the

Directives regarding electromagnetic

version with

pump only

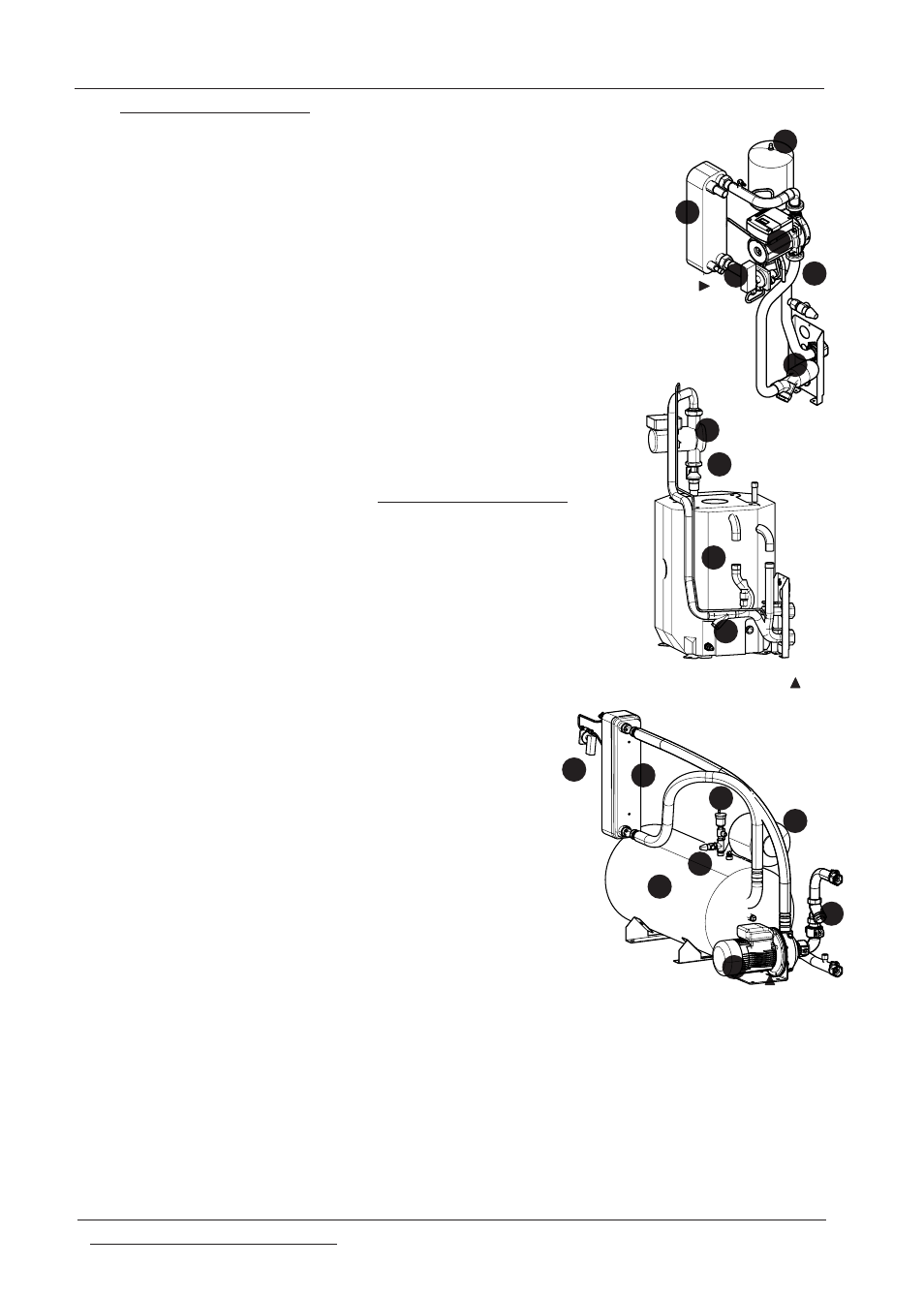

EXAMPLES OF HYDRAULIC CIRCUITS

the diagrams shown here are an example

version A ECL

020÷040 WITH

FLOODED

EVAPORATOR

KEY

1 Circulator/pump

2 Differential pressure switch/flow meter

(ECL 020÷040A)

3 Safety valve

4 Expansion vessel

5 Water filter

6 Plate heat exchanger

(inside the storage tank in ECL

020÷040A)

7 Vent valve

8 Storage

9 Electric resistance (ACCESSORY)

VERSION A 100 - 200

1

2

3

4

5

6

2

1

5

8

1

2

3

4

5

6

7

8