Ecochill chiller, Thermostatic valve, Liquid and discharge line taps – Airedale EcoChill 6kW - 46kW User Manual

Page 11: Ventilation unit

11

EcoChill

Chiller

Technical Manual 7300221 V1.1.0_02/2013

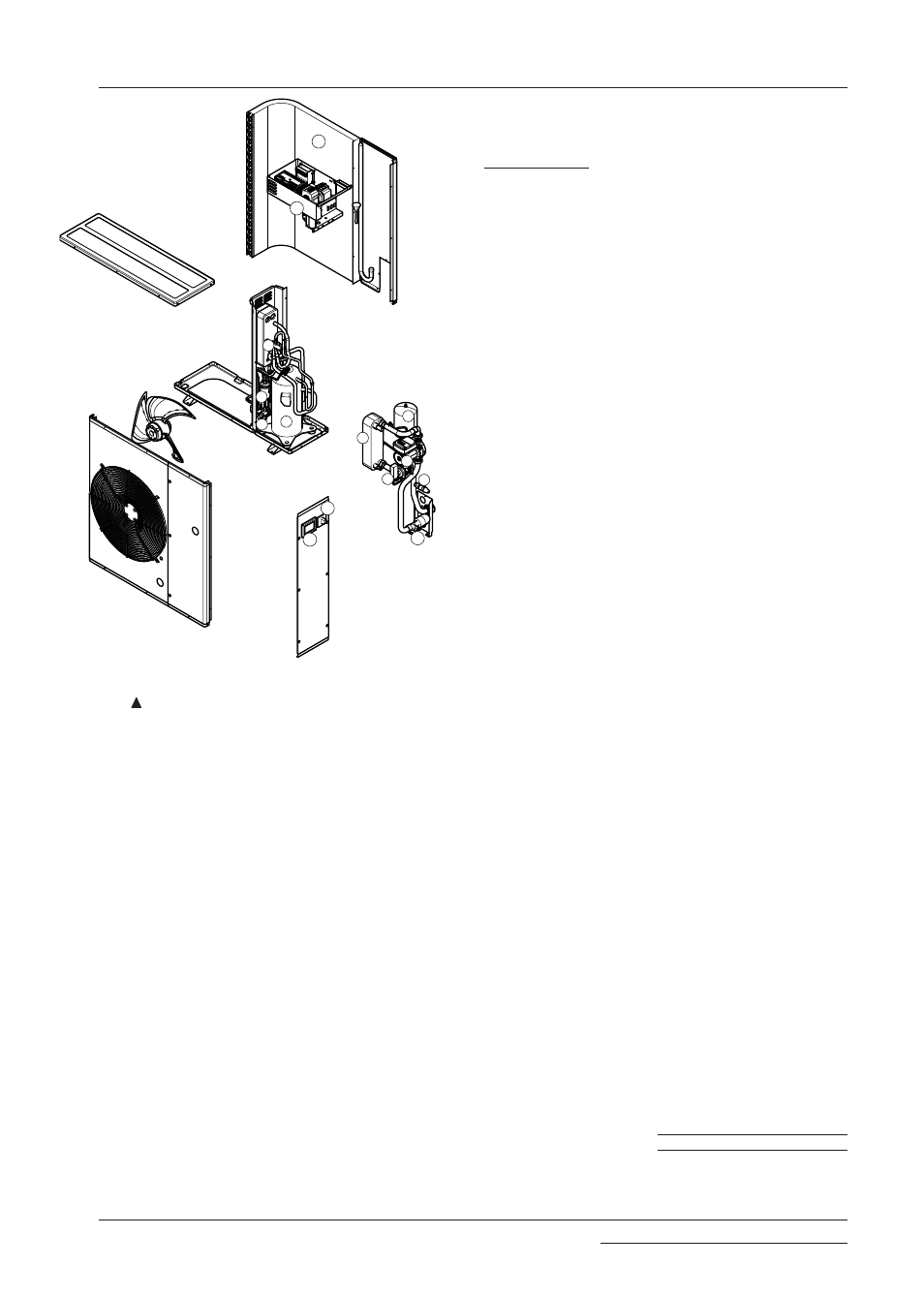

2. DESCRIPTION OF THE

COMPONENTS

2.1. COOLING CIRCUIT

Compressor

− High efficient scroll

compressor, activated

by a 2 pole electric

motor with internal

temperature protection.

They are supplied as

standard with crankcase

resistive heater. The

compressor is mounted

on rubber anti vibration

mounts.

Air-side heat

exchanger

Made with

copper coil with

aluminium louvered

fins blocked

by mechanical

expansion of the

pipes. Provided with

coil guard.

Water-side heat exchanger

Plate type, isolated externally

with closed cell material to reduce

heat loss. IN A VERSIONS in sizes

020 - 025 - 030 - 040 it is positioned

inside the water storage tank.

Dehydrator filter

Mechanical type filter realised in

ceramics and hygroscopic material,

able to collect any non condensables

within the the cooling circuit.

Thermostatic valve

Mechanical valve, with external

equaliser positioned at evaporator

outlet, modulates the flow of gas to

the evaporator, depending on the

heat load, in order to ensure a correct

superheat.

Liquid and discharge line taps

("C MOTOR CONDENSING"

versions)

Allows interruption of the refrigerant

in the case of extraordinary

maintenance.

HOT GAS INJECTION

Solenoidvalve

− (for heat pump only.)

− The valve positioned between the

compressor and the thermostatic

valve outlet controls:

− Defrosting cycles without having to

reverse the cycle

− Safety capacity control if the pres-

sure should rise on the discharge

line

HOT GAS BY-PASS INJECTION

VALVE

Only D version

Device for hot gas injection of

evaporator, mounted on versions with

partial recovery.

Cycle reversing valve

(for heat pump only.)

Reverses the flow of refrigerant on

variation of summer/winter mode and

during any defrosting cycles.

One-way valve

Allows one-way flow of the refrigerant.

Liquid storage

(for heat pump only.)

Compensates for the internal volume

differences between louvered fin coil

and plate exchanger, withholding

excess liquid during winter operation.

FRAME AND FANS

Ventilation unit

Helical type, balanced statically

and dynamically. Electric fans are

protected electrically by magnet-circuit

breakers and mechanically by anti-

intrusion metal grids, according to IEC

EN 60335-2-40 Standard.

Support frame

Made in hot galvanised sheet steel

with suitable thickness and painted

with polyester powders for corrosion

protection.

KEY

1 Scroll compressor

2 Thermostatic valve

3 Dehydrator filter

4 Cycle reversing valve

5 Plate heat exchanger

6 Differential pressure switch

7 Circulation pump

8 Expansion vessel

9 Safety valve (6 bar)

10 Water filter

11 Exchanger coil

12 Electric box

13 MODUCONTROL display

14 Door-lock isolating switch

1

2

3

4

5

6

7

8

9

10

11

12

13

14