Ethylene glycol correction factors, It cooling logicool ™ onrak – Airedale OnRak 3kW 35kW User Manual

Page 17

IT Cooling

LogiCool

™ OnRak

IT Cooling

17

Technical, Installation and Maintenance Manual :6912497 V1.5.0 02_2013

Ethylene Glycol Correction Factors

Calculation of Design

Volumetric Flow Rate (l/s)

The maximum design volumetric flow rate can be calculated using the following equation:

V

=

Q

x Cp x ΔT

Where:

Q

=

Cooling Capacity (kW).

T

=

Temperature Difference between Water/Glycol Entering/ Leaving (°C).

=

Density of Glycol/Water mixture at design condition. Refer to table below.

Cp

=

Specific heat capacity at design condition. Refer to table below.

Calculation of Indoor Unit

Pressure Drop (

Ps)

The maximum indoor unit pressure drop can be calculated using the following equation:

Ps=

Pw x P

Using the volumetric flow rate calculated above, the pressure drop (

Pw) can be taken from the relevant

pressure drop graph..

Where:

Ps

=

Maximum Water/Glycol Pressure Drop for the indoor unit (kPa).

Pw

=

Equivalent Water Pressure Drop for indoor unit (kPa).

P

=

% Glycol Pressure Drop Correction Factor @ 10°C Water Temperature.

Refer to table below.

The resultant pressure drop (

Ps) is the maximum pressure drop based on the indoor unit

running at the prescribed conditions.

This will typically occur when the water/glycol temperature is approximately 10°C.

The indoor unit pressure drop will change at other operating conditions.

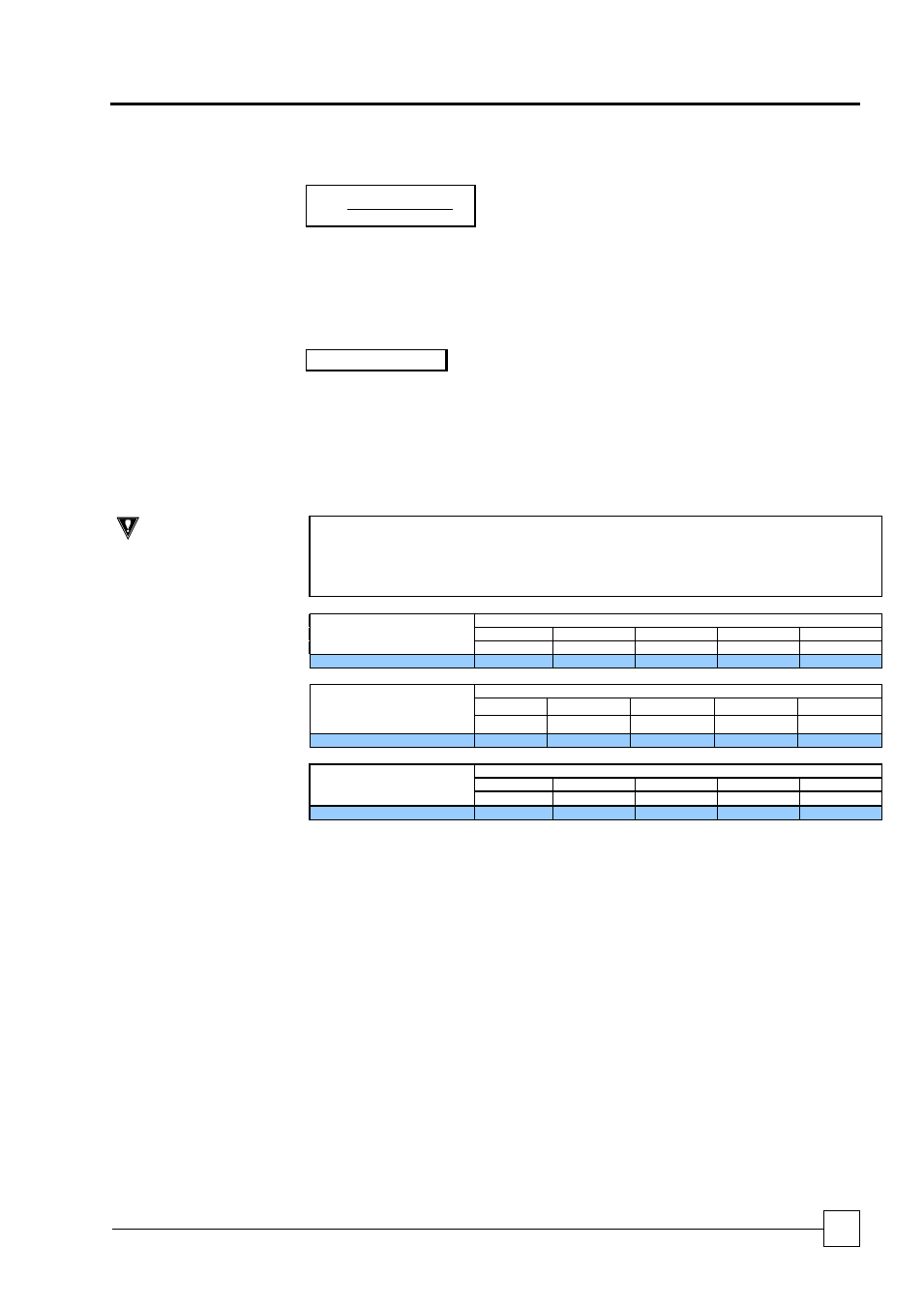

Specific Heat Capacity (Cp)

Water/Glycol Temperature °C

Ethylene Glycol (Volume) / Freezing Point °C

0% / 0°C

10% / -4°C

20% / -9°C

30% / -15°C

40% / -23°C

Cp

Cp

Cp

Cp

Cp

10

4.193

4.064

3.918

3.773

3.606

Density (

)

Water/Glycol Temperature °C

Ethylene Glycol (Volume) / Freezing Point °C

0% / 0°C

10% / -4°C

20% / -9°C

30% / -15°C

40% / -23°C

10

998

1008

1018

1027

1037

Pressure Drop Correction

Factor (P

)

Water/Glycol Temperature °C

Ethylene Glycol (Volume)

0%

10%

20%

30%

40%

P

P

P

P

P

10

0.983

1.0125

1.027

1.045

1.067

(1) All data based upon ASHRAE fundamentals 2001.