SHIMPO FG-3000 User Manual

Page 5

5

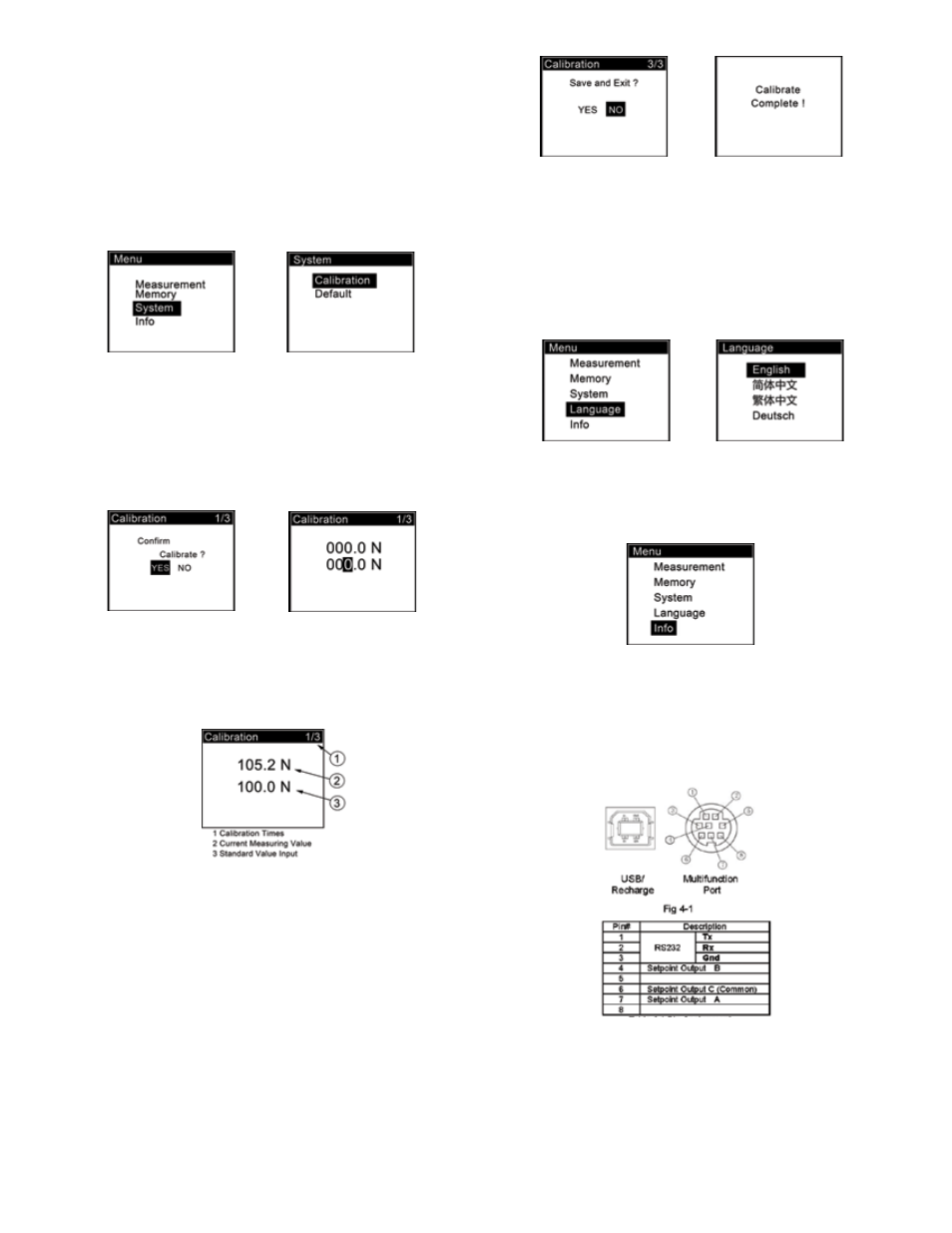

Fig. 5-6(d) Fig. 5-6(e)

5.7 Default

With this function, the force gauge can be restored back to the

original factory settings. Only perform this function when all other

troubleshooting tactics have first been attempted.

6. LANgUAgE

The force gauge can display in various languages. Set the lan-

guage as desired. See Fig. 6.

Fig. 6

7. INFO

Information about the force gauge such as model, version and

serial number is provided in this menu. Fig. 7

Fig. 7

8. COMMUNICATION PORT

The force gauge has a USB for recharging and communicating

with a PC, plus an 8 pin connection for printer connection and set

point output. Fig. 8-1

Fig. 8-1

5.6 Calibration

Because of the sensor material performance or the influence of

external factors, there may be errors of a certain level after

a period of usage.

It is recommended to send the force gauge to a specialized test-

ing organization for calibration.

If you have standard force weights or other standard load and a

test stand, you may utilize this function and procedure to calbrate

the sensor.

Fig. 5-6(a)

1) Mount the force gauge.

2) Use the tare by use of the ZERO key.

3) Enter Calibration sub-menu as in Fig. 5-6(a).

The calibration interface is shown in Fig. 5-6(b).

Fig. 5-6(b)

4) Load a standard force. Now the value in the standard input area

is just equal to the current measured value. Wait a moment for the

force to stabilize.

Fig. 5-6(c)

5) Press ZERO and MODE to input the standard force value.

6) Press MENU to enter the next calibration. Press LOG to inter-

rupt the calibration.

When 3 calibration points have been finished, a confirm window

will pop up asking to “Save and Exit”(YES)/(NO). Fig. 5-6(d)

Press ZERO or MODE to select, then press MENU.

If “YES” is selected, Calibration is complete. Fig. 5-6(e)