KROHNE BM 26 A EN User Manual

Page 18

18

Installation and Operating Instructions BM 26 A

1.6.3 Changing the process conditions

If the user wishes to use the BM 26 A to measure another product, then the following points should

be noted:

• Contact KROHNE for advice and information on equipment / product compatibility especially

where use in hazardous areas is concerned.

• Ensure that Pressure Equipment Directive 97/23/EC is observed, if relevant.

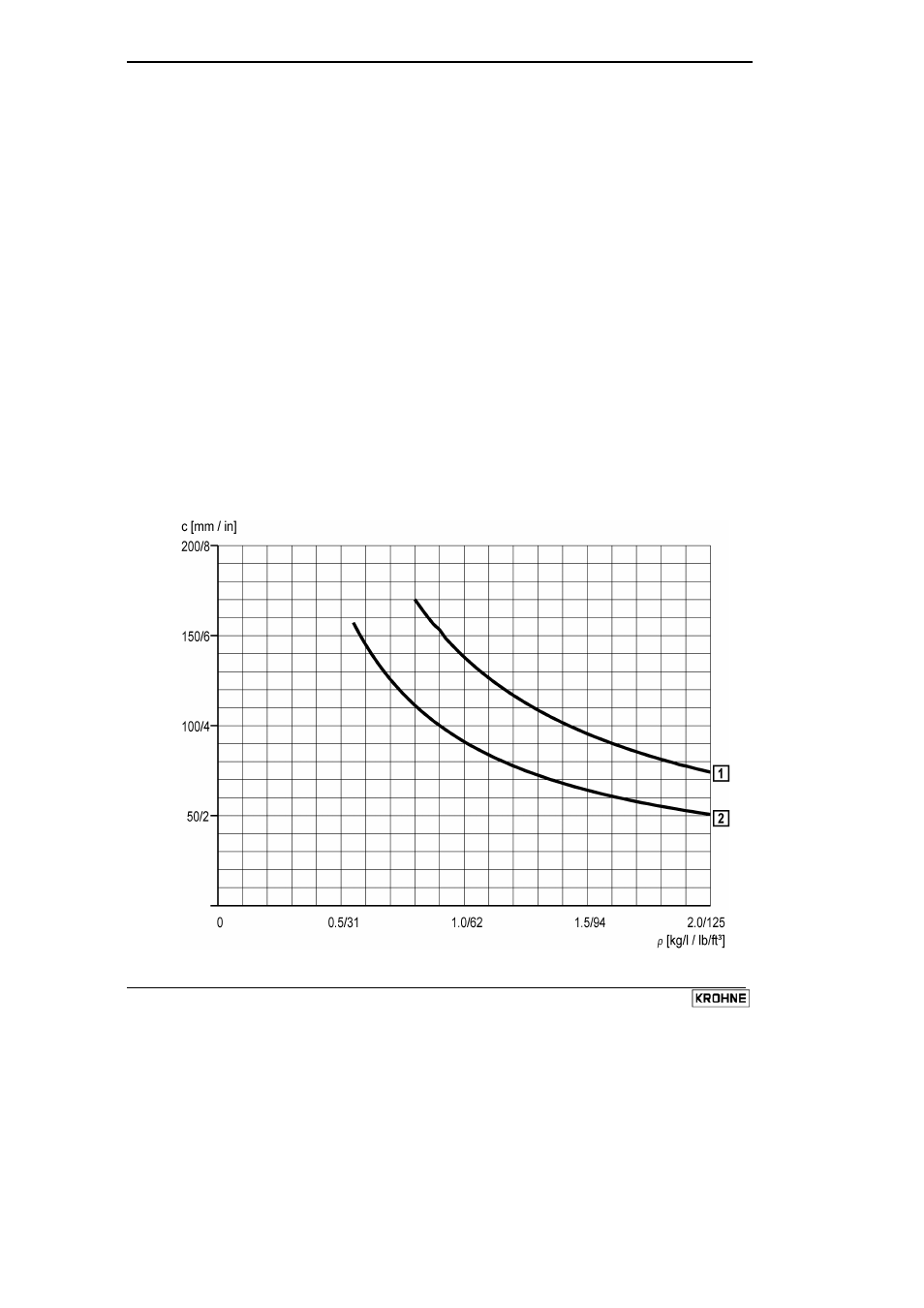

• The depth of immersion “c” (see section 1.6.4) of the float increases as product density

decreases. This depth is also dependent on the float model (No. 1, 2, 3 or 4) and material used

(316L, 316Ti or titanium). The new depth of immersion “c” is shown on the two line graphs

below. Further information is available from KROHNE on request to accurately calibrate your

instrument. When contacting KROHNE remember to:

−

quote KROHNE references (order / fabrication no.) for the BM 26 A in question

−

identify the new product and give its density at the new operating conditions.

−

give information about the old application. Floats may have been especially adapted

for specific applications; for example: density- adjusted (pressurized) or floats for low

density applications and floats with ballast for interface measurement.

• The top of the float must be no more than 35mm or 1.38” above the product surface to ensure

reliable floatability and accurate measurement.

Graph 1: Float immersion depth against product density

Line 1 : Float no. 1 made of 316Ti (1.4571) or 316L (1.4404), wall thickness 1mm or 0.04”

Line 2 : Float no. 2 made of 316Ti (1.4571) or 316L (1.4404), wall thickness 0.6 mm or 0.02”

Where c is immersion depth and

ρ is product density