KROHNE VFM 1091 User Manual

Page 8

8

•

Check that the system has been correctly installed as described in Sect. 1, 2 and 3.

•

Before initial start-up check that the following details on the nameplate agree with the data specified in the report of settings for the signal

converter. If not, reprogramming will be necessary.

Meter size Fct3.1.1, Sect. 6.1, 6.2.5.

K-Factor Fct 3.1.2, Sect. 6.1, 6.2.5.

•

The flowmeter is ready for service 15 minutes (waiting time) after switching on the power source. Increase flow velocity slowly and steadily.

•

Avoid abrupt changes in pressure in the pipeline.

•

If the process medium is steam, condensate may form initially and cause faulty measurements when the system is started up for the first time.

•

When powered, the signal converter normally operates in the measurement mode. The power-on sequence to measurement mode is as follows:

“TEST” is displayed for approx. 3 seconds followed by

“VFM 1091 ” the instrument type followed by

“Ver x.xx” the software version of the instrument.

Then instrument operates in measurement mode where it displays the parameter being measured Or FATAL ERROR if there are one or more

critical errors detected (For description on errors refer Sect. 5.5.)

•

The pulse output is galvanically isolated from the 4-20mA current output and may be optionally grounded.

•

All functions and operating data are programmable; see Section 5, 6.1 6.2.9

•

Factory-set data and functions are listed in the enclosed report on settings. This can also be used to record any changes made to the operating

parameters.

•

Passive frequency output, open collector for connection of active electronic counters EC or switchgear, input voltage 5 to 25V, load current max.

100 mA, min load resistance RL 250, selectable pulse width duty cycle or 250 mSec

3.3.4 Pulse out put

4. Start-up

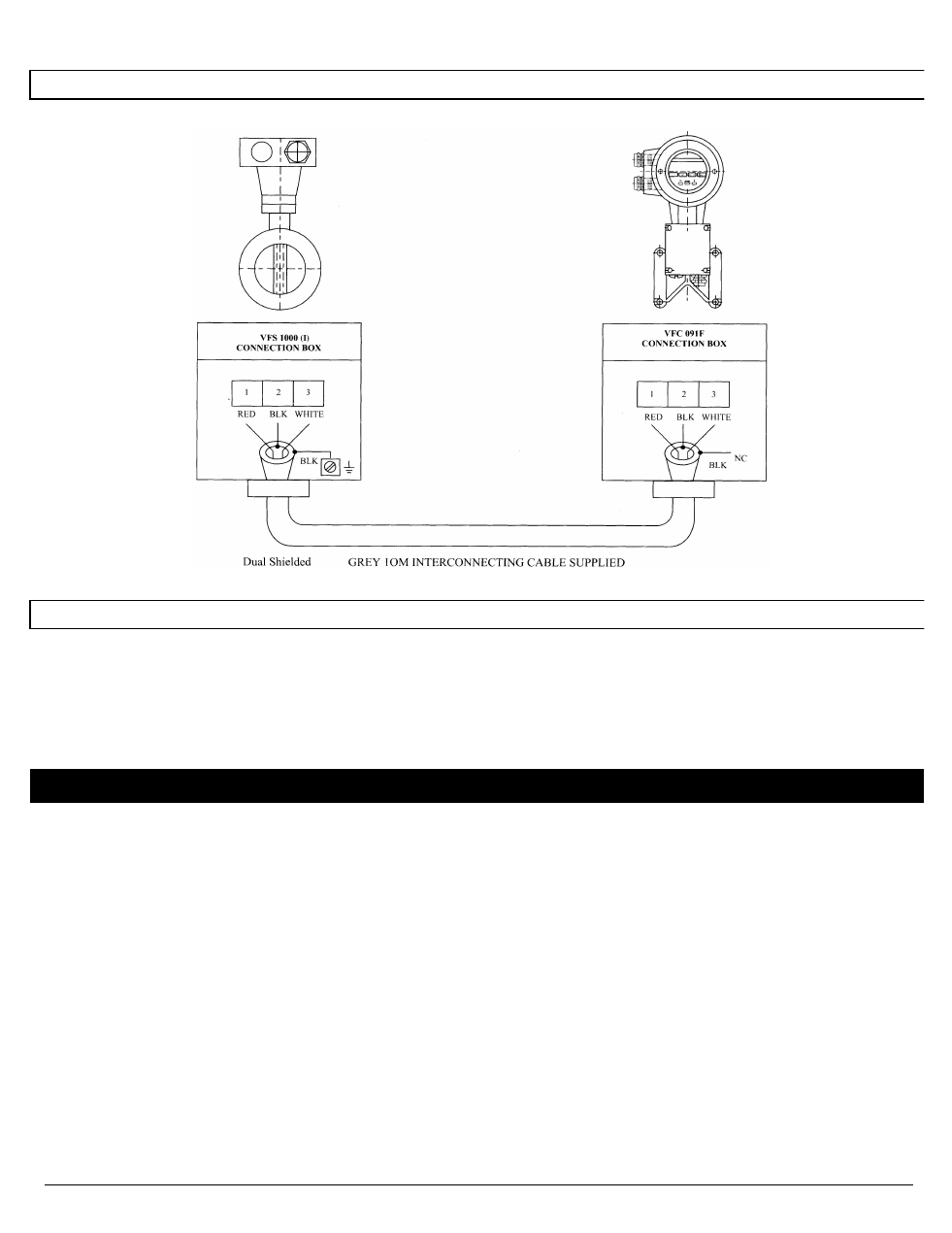

3.3.3 Connection between VFS1091 & VFC 091F