KROHNE VFM 1091 User Manual

Page 41

Measuring principle

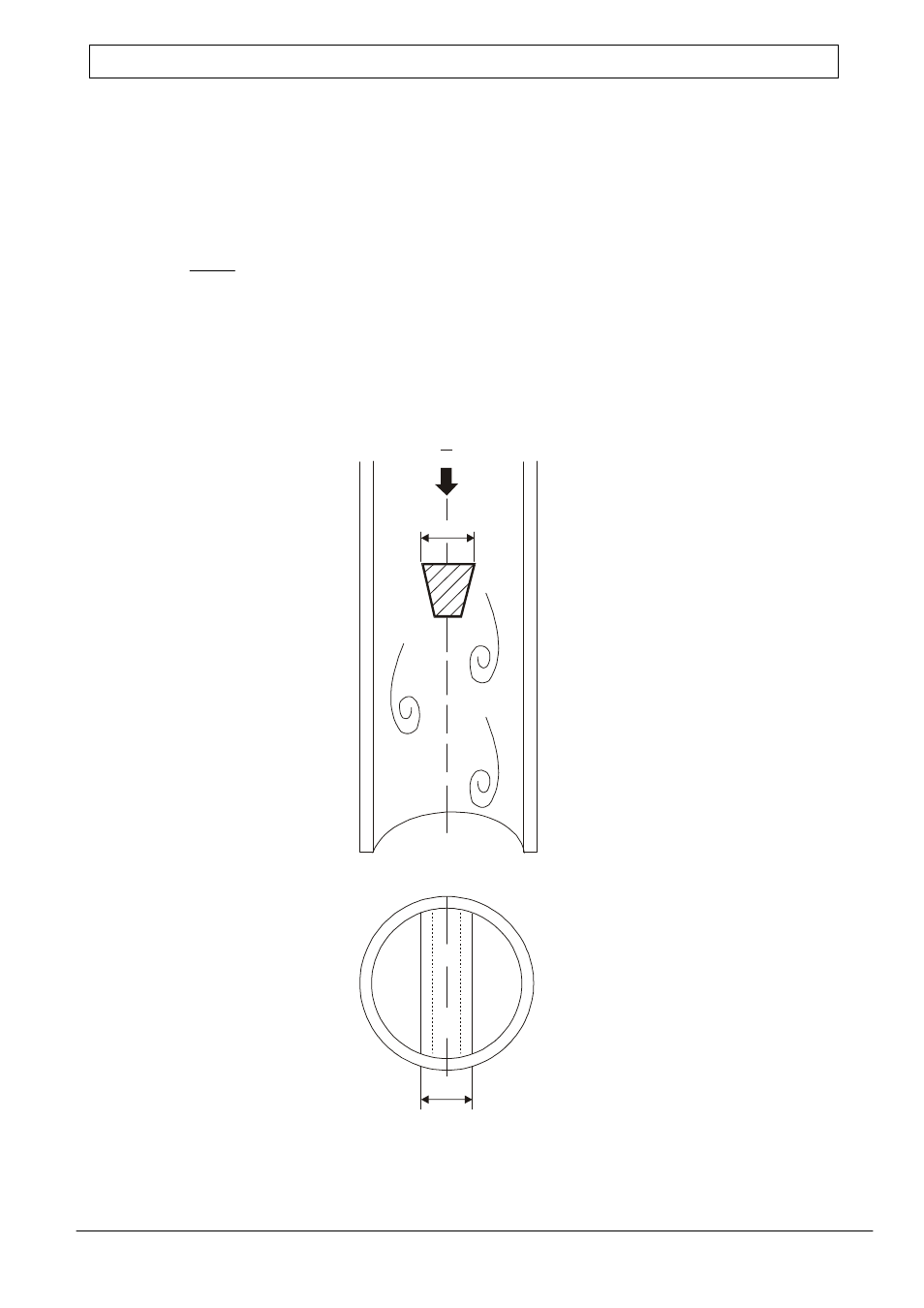

The Vortex flowmeter is used for measuring the flow velocity of fluids in pipelines. The measuring principle is based on the

development of a Karman Vortex shedding street in the wake of body built into the pipeline. In theory, this process enables

measurements to be carried out in turbulent flows with a Reynolds number Re > 1091, but linear measurements are only possible

where Re > 20 000.

The periodic shedding occurs first from the one side and then from the other side of a bluff body (Vortex- shedding body) installed

perpendicular to the axis. Vortex shedding generates a so-called "Karman Vortex Street" with alternating pressure conditions whose

frequency f is proportional to the flow velocity v. The non dimensional Strouhal number S (primary head constant) describes the

relationship between vortex shedding frequency F. (in Hz), width b of the body and mean flow velocity v (in m/s)

F = S

*

v

b

The flexural vibration of the vortex-shedding body is picked up in the primary head via sensors and analysed in the signal converter.

In the case of gaseous, flowing media, the vibration frequency ranges between 10 and 7000 Hz.

To permit the mass rate of flow to be calculated from the volume rate of flow, either product pressure and temperature or product

density at the installation location of the flowmeter must be known factors.

Karman Vortex Street

v

b

b

41