Part c function checks and trouble shooting hints – KROHNE VFM 1091 User Manual

Page 26

Part C Function Checks and Trouble shooting hints

This section describes some functional checks, which can be

performed without using any special equipment. It must be

noted that these checks are very preliminary and do not check

all the functions of the primary head or the signal converter.

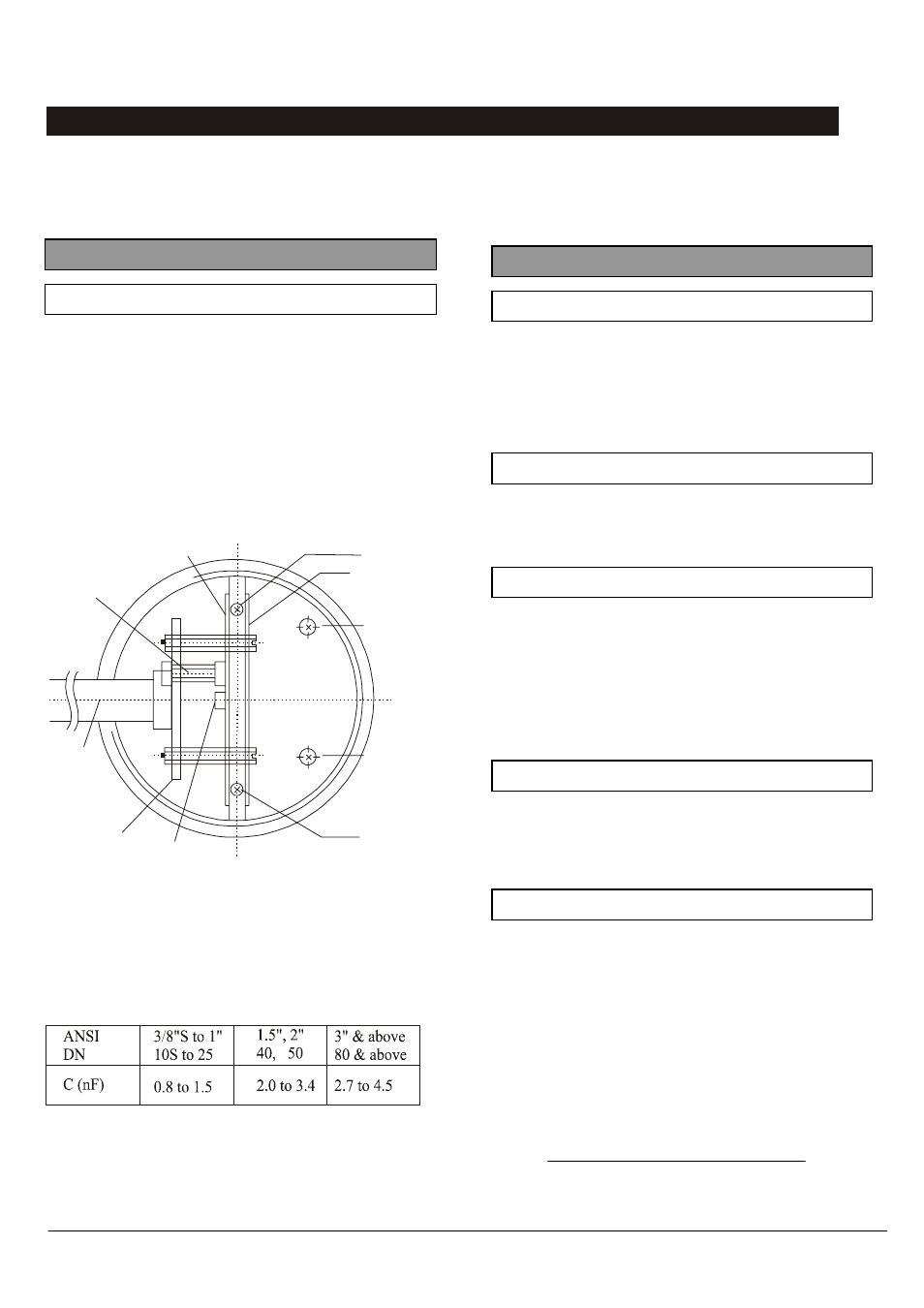

To perform preliminary testing of the vortex piezo sensor, the

signal cable of the piezo sensor should be disconnected from

the signal converter electronics. To do this

Always switch-off power source before commencing

work.

l. Use the special wrench to remove cover from

the

electronic

compartment.

Ensure

that

screw

threads

of

electronic

compartment

cover

are

well greased at all times.

2. Remove screws A and turn display board to one side.

3. Remove the piezo cable from the preamplifier board at

location Z by its (and not by pulling cable itself!)

4. Do the following tests on the sensor cable

Capacitance between centre pin and each outer pin

Resistance between center pin and each outer pin

>200M ohm. Also resistance between each sensor

7. Functional checks

wire pin and earth should be >200 M ohm. Also short out

all three pins & measure resistance between these pins &

Earth. This should be > 200 M W

5. Reassemble converter.

7. 1 Primary head functional checks

7. 2 Signal converter functional checks

7.2 Vortex Sensor

7. 2 .1 Self diagnostics

On

power-on

VFC

091

carries

out

diagnostic

checks wherein the instrument checks its functional elements

as

far

as

possible.

Diagnostic

failure

result

in fatal errors and are indication of a hardware fault

within electronics. Usually it is necessary to replace

electronics in such cases.

7. 2 .2 Display check

Display functionality can be checked by the use of

Fct 2.1 TESTDISP.

This function flashes all the segments of the display.

Preamplifier

flat cable from

CPU to Preamp

board

A

Power

supply

board

D

D

Z

A

Flat

cable to

display

board

CPU board

7. 2 .3 Current output check

Fct.2.2 TEST I can be used to test current output function of

VFC 091. With this function it is possible to generate

following

test

values-

between

4

and

20mA

(integer values only)

Current output electronics is factory calibrated and

should be within +/- 0.02mA. Otherwise re-calibration of

current output is necessary by KHRONE MARSHALL

service person.

7. 2 .4 Pulse output check

Fct. 2.2 TEST P is meant for checking the pulse output

function with a power supply (24VDC) connected through a

load of lk/1W to pulse output terminals 4.1 & 4.2, and the

output level (high or low) monitored with a voltmeter.

7. 2 .5 Frequency measurement check

Disconnect the sensor cable from the electronics as indicated

in section 7.1.1 and feed a signal (sine or square wave) to the

sensor connector Z on the preamplifier board. The signal

should be fed between the center pin and one of the outer pins

of the connector Z. The value of frequency fed should be

indicated on the display when frequency measurement is

enabled. This can also be checked with the help of the VS1 or

VS2 Vortex Simulator in place of the signal source. The

amplitude of the signal l should be 50mVp-p and the

frequency between 2Hz and a value

equal to Qmax (m/hr) x K-factor (Pulses/m) max

3600

26