KROHNE VFM 1091 User Manual

Page 6

6

•

In case of steam or compressed gas, a moisture separator may be used

50D upstream of the meter if the dryness fraction is less than 95%.

•

For gases, a filter or strainer may be used to remove solid particles.

This is specially important for meter sizes below 1".

•

Meter sizes DN25, 40, 50, 80, 100 and 150 (1" to 6")

•

Pipe flanges

(Pressure Ratings

DIN: DN25/PN40, 100; DN40/PN40, 100;

DN50/PN40, 64, 100; DN80/PN40, 64, 100;

DN100/PN16, 40, 64 and DN150 / PN16, 40.

ANSI: 1" to 6” / #150, 300 SORF)

•

Gaskets inside diameter must be greater than the inside diameter of the

Primary head, e.g. Use flat gaskets to DIN 2690, Gaskets must not

project into the effective pipe cross sectional area. washers, nuts and

bolts are

•

Bolts, nuts and washers are supplied with meter, check flange

connection for leak-tightness after flowmeter installation.

•

Meter sizes DN10S, 10, 15, 20, 25, 40, 50, 80, 100, 150

and 200 (3/8"S to 8")

•

Pipe flanges

(Pressure ratings

DIN: DN25/PN40, 100, DN40/PN40, 100; DN50/PN40, 64, 100;

DN80/ PN40, 64, 100, DN 100 /PN16, 40, 64; DN150/PN16,

PN40, DN200/PN10, 16 and

ANSI: 1/2” to 8" / # 150, 300 SORF)

•

Gaskets are supplied by us with flanged unit.

•

check flange connection for leak-tightness after

flowmeter installation.

To measure the temperature and pressure of the medium for either mass

flow/normalized f1ow computation using external flow computer or

measure operating density using external pressure and temperature

measurement (e.g. to feed the density value in the VFM off-line mass

or normalized flow computation) suitable measuring points should

Installation upstream of f1owmeter

Min. distance: 20*DN (DN = meter size)

Installation downstream of flowmeter

Min. distance: 5*DN (DN = meter size)

Allowance must be made for the pressure drop in the flowmeter as

correction value for operating conditions prevailing upstream of the

flowmeter.

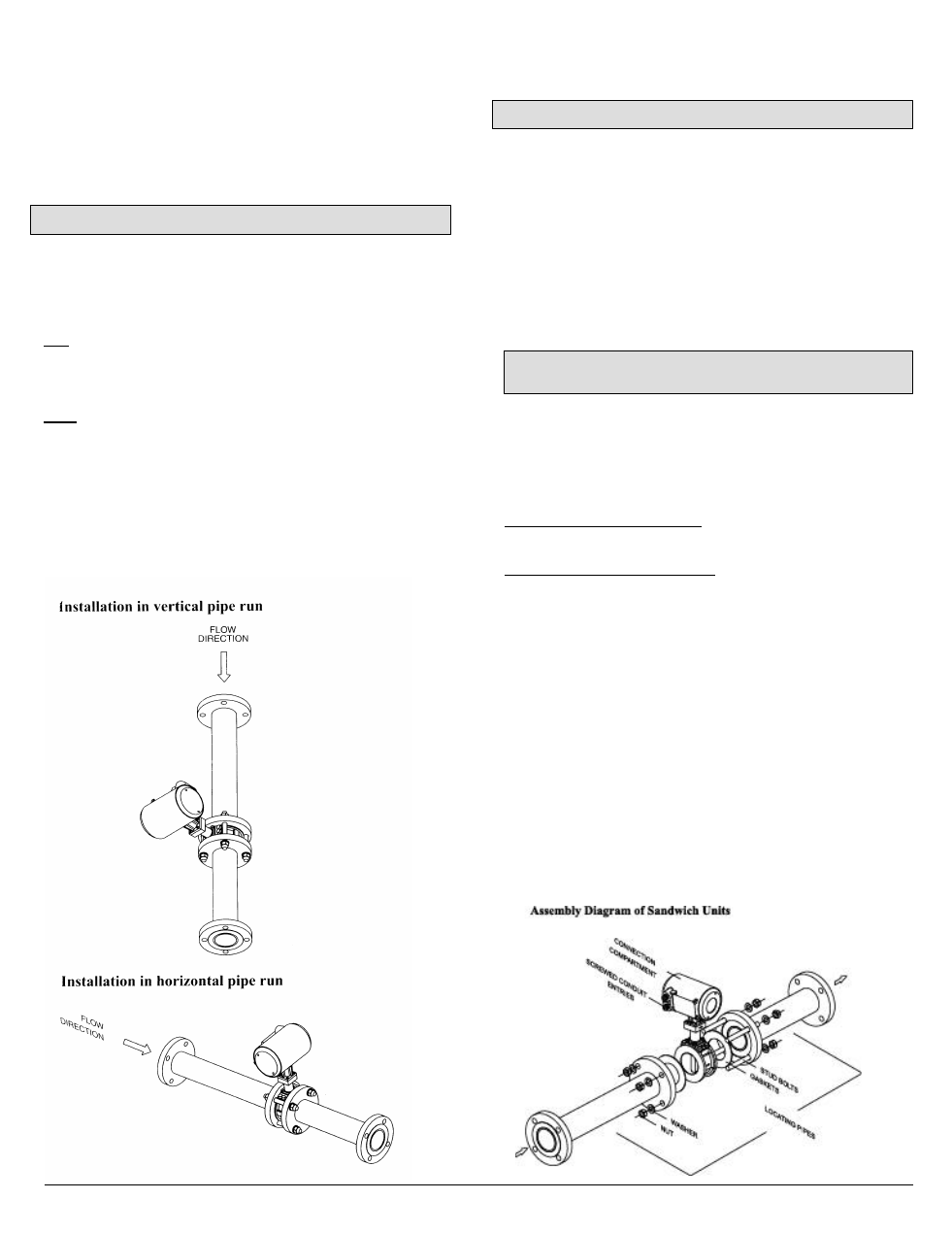

2.2 Sandwich type to DIN 19205 / ANSI

2.3 Flanged type to DIN 2501 / ANSI B 16.5(SCH-40)

2.4 Temperature / Pressure measurement for External density

compensation