10 coding desired for entry into programming mode, 11 behavior of outputs during programming, 12 hart programmability – KROHNE VFM 1091 User Manual

Page 23

Fct. 1.3.2 RANGE P Pulse output range value

Pulse output is 0 Hz for 0 flow rate and a value (P

100%

) equal to Q

100%

* RANGE P value.

Example of pulses/unit volume or mass

Full scale setting, Q

100%

:

1000 Litre/hr (set via Fct. 1.1.2)

RANGE P : 1PULS/Litre

(set

via

Fct. 1.3.2)

at 1000 litres per hour

:

1000 pulses per hour would be the pulse output.

For limits on programming of RANGE P refer to Sect. 6.

Fct.1.3.3 PULS. WIDTH pulse width

This is used to limit the active duration of the Pulse output, to 250mSec and thereforc

reduce the overheating of external electromechanical totalizers coil.

For details refer to Sect. 6.

TESTING OF PULSE OUTPUT P

Fct.2.3 TEST P can be used to check Pulse output. The Pulse output may be set to ON or OFF state. This may be monitored with the help of a

voltmeter connected across the pulse output which is wired to a power supply & load in series. The normal pulse output function is restored

automatically [as per programming of Pulse output] when the measurement mode is resumed.

6.2.10 Coding desired for entry into programming mode

Fct. 3.2.1 ENTRY. CODE.1 set to YES for enabling Code l.

The entry code consists of 9 keystrokes of the 3 keys as follows

Programming of the VFM 1091(I) is "off-line" meaning that the instrument stops making measurements when it is in the programming mode. This

means VFM 1091(I) will keep totaliser value and Current/Pulse output as per the last value output before entering the programming mode.

6.2.11 Behavior of outputs during programming

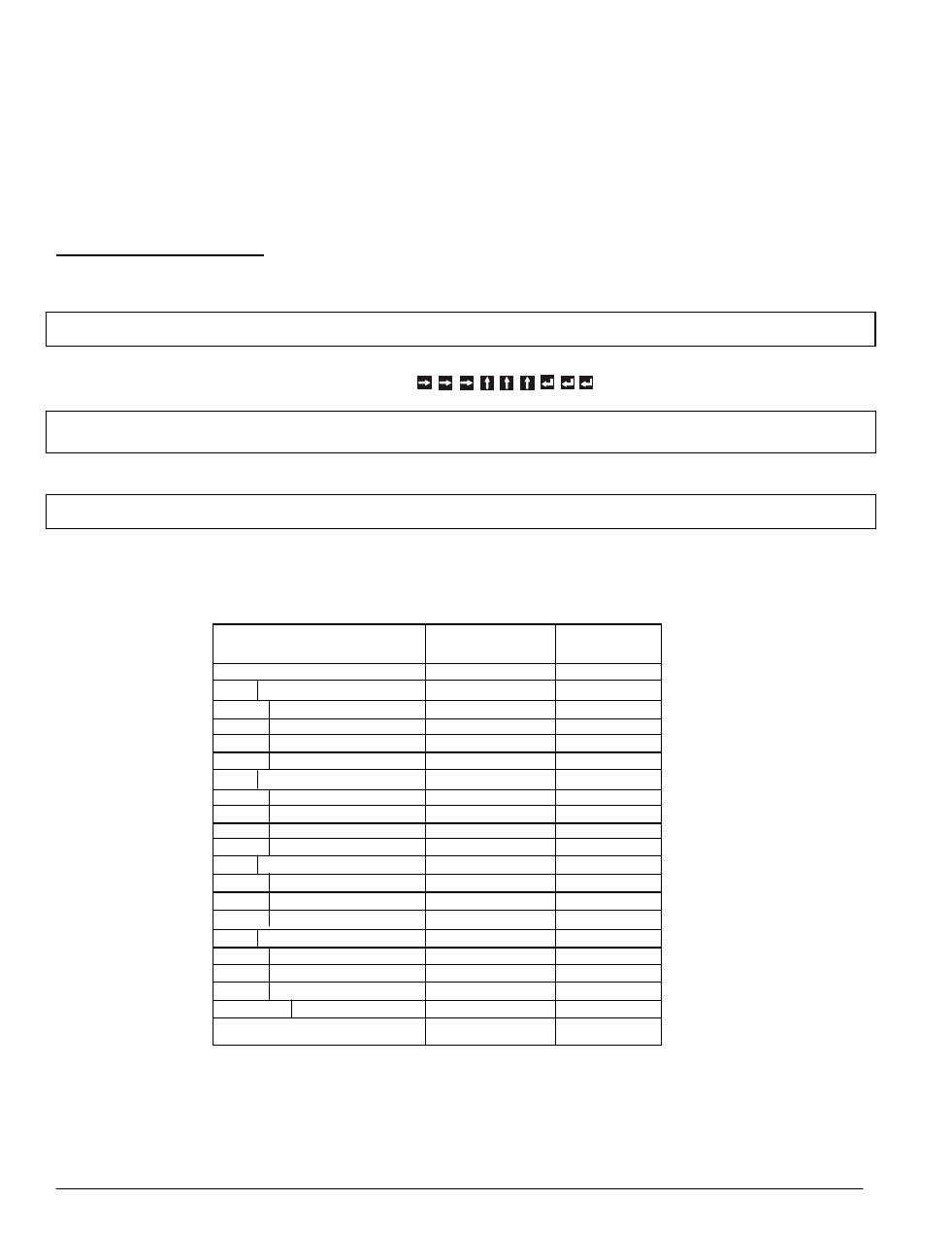

6.2.12 Hart programmability

VFM 1091(I) supports all the Universal commands and the Common practice commands which are applicable to the meter.

The HART

®

compatibility of VFM 1091(I) program functions is tabulated below. For functions which are HART

®

programmable, corresponding

Generic On-line Menu (GOM) step of HART

®

Communicator is also given. Details of Generic On- line menu is given in 6.2.14.

PROGRAMMING FUNCTION

HART

HHC MENU

PROGRAMMABILITY

FST 1.0 OPERATION

FCT. 1.1.0 BASIS.PARAM

FCT. 1.1.1 MEAS.INST

YES

GOM 1,2,3

FCT.1.1.2 MAX. FLOW

YES

GOM 1,3,2

FCT 1.1.3 MIN. FLOW

YES

GOM 1,3,3

FCT. 1.1.4 TIME CONST

YES

GOM 1,3,6

FCT. 1.2.0 DISPLAY

FCT 1.2.1 FLOW UNITS

YES

GOM 1,3,2

FCT 1.2.2 TOTAL UNITS

TO

FCT. 1.2.6 CYCLE DISP

NO

FCT 1.3.1.0 PULS.OUTP NO

FCT. 1.3.1 FUNCTION P

TO

FCT. 1.3.3 PULS. WIDTH

NO

FCT 2.0 TEST

FCT. 2.1 TEST DISP

NO

FCT 2.2 TEST 1

YES

GOM 1,2,2

FCT 2.3 TEST P.

NO

FCT 1.1. MEAS.INST

YES

FCT 3.0 INSTALL

NO

**

Notes:

* GOM 1,3,2 is used to set the primary sensor unit. When primary sensor unit is changed, device automatically updates the MEAS.INST. As an

example, if the unit is changed to Kg/hr, then MEAS.INST will be set to MASS.

** Fct 3.0 install menu contains the device specific set up.

23