KROHNE VFM 1091 User Manual

Page 5

5

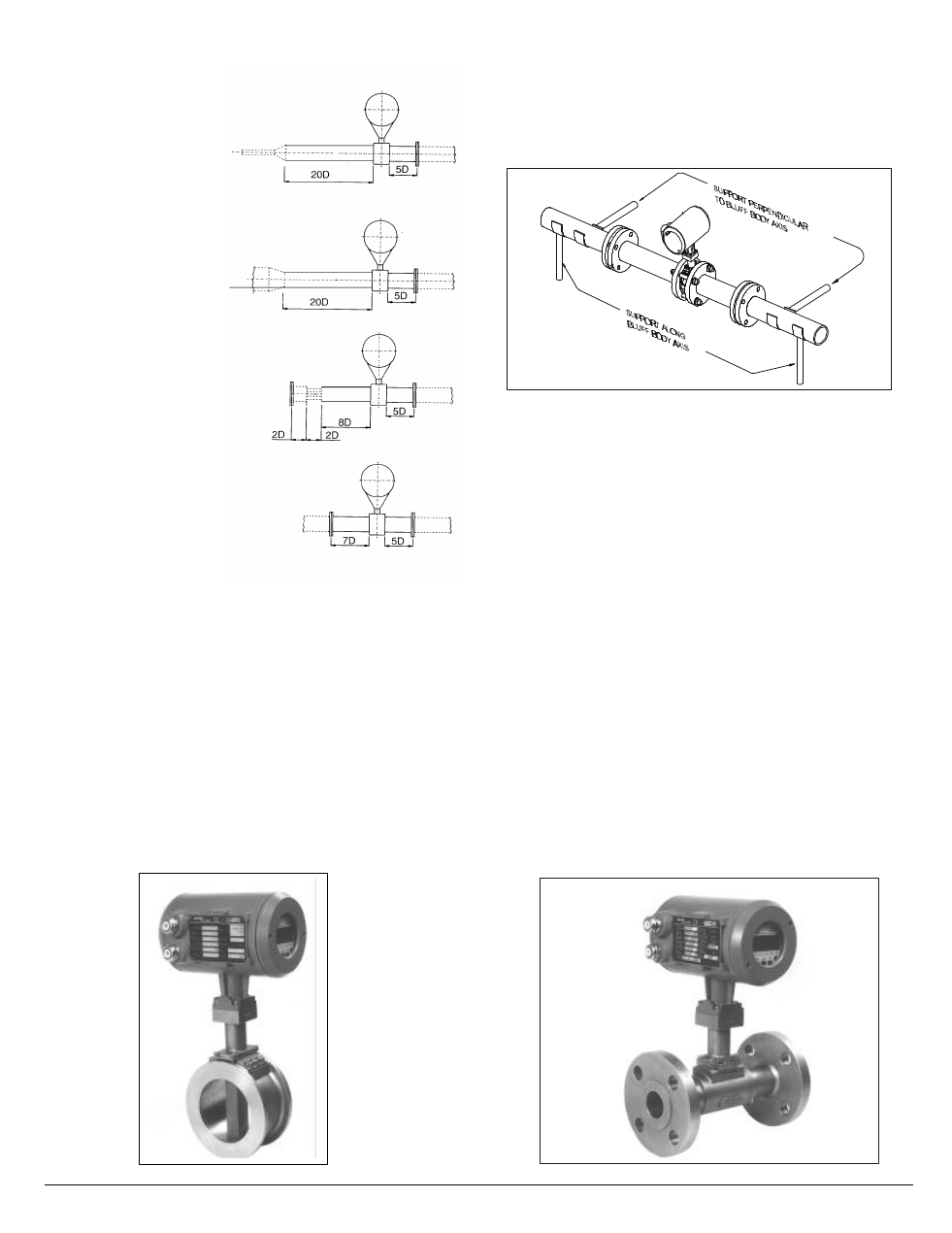

EXPANDER

REDUCER

FLOW STRAIGHTENER

SPACIAL FLOW STRAIGHTENER

With flow straightener the inlet pipe length may be halved e.g. for a

control valve the inlet length is 25D instead of 50D. The minimum inlet

pipe length including flow straightener must always be 12 D.

The small sizes (below 1" or DN 25) come with upstream &

downstream pipelines & flange connections to suit customer's flanges.

4. Pipe vibration

Caused, for example, by the action of pumps, valves, etc., will falsify

measurements particularly at low flow velocities. Support the pipeline

on both sides of the flowmeter; in the direction perpendicular to both

the pipeline & bluffbody axis.

SANDWICH VERSION

Flexible pipes or bellows may be used before the upstream and after the

downstream in case the vibrations are too high. Pipe vibration limit is

0.2 g peak to peak up to 8-500 Hz crossover frequency. (which equals

0.75 mm)

5. Pipeline along a wall

Where possible, the distance between the pipe centerline and wall

should be greater than 0.5 m (20”). If it is less, first connect all cables

to terminals in the connection compartment (power supply and outputs)

and run them via an intermediate connection box (see also Section 3)

before installing the flowmeter.

Do not lag (Thermally insulate) the meter body.

6. Orientation

•

Turn the Display board through ±90 or 180 to obtain horizontal

positioning of the display.

•

Turn the signal converter housing through ±90

0

or 180

0

should that

be more suitable for the location of the installation.

7. State of Medium

•

Ensure single-phase flow. Liquid droplets in gas / vapour, solid

particles in gas/liquid & gas bubbles in liquid are not permitted.

In Liquid application e.g. water; to prevent cavitation, minimum D/S

pressure is given by the relation:

Pds (bar_g) >= (2.9* DP)+ (1.3 * Ps) - 1.013

where DP= pr.drop of VFM in Bar from sizing

program.

Ps= Sat.pr.in Bar at op.temp

FLANGED VERSION