Technical data, 2 technical data – KROHNE OPTITEMP TT 30 C-R EN User Manual

Page 36

7

TECHNICAL DATA

36

OPTITEMP TT 30 C/R

www.krohne.com

11/2012 - 4000753302 - MA OPTITEMP TT 30 C/R R02 en

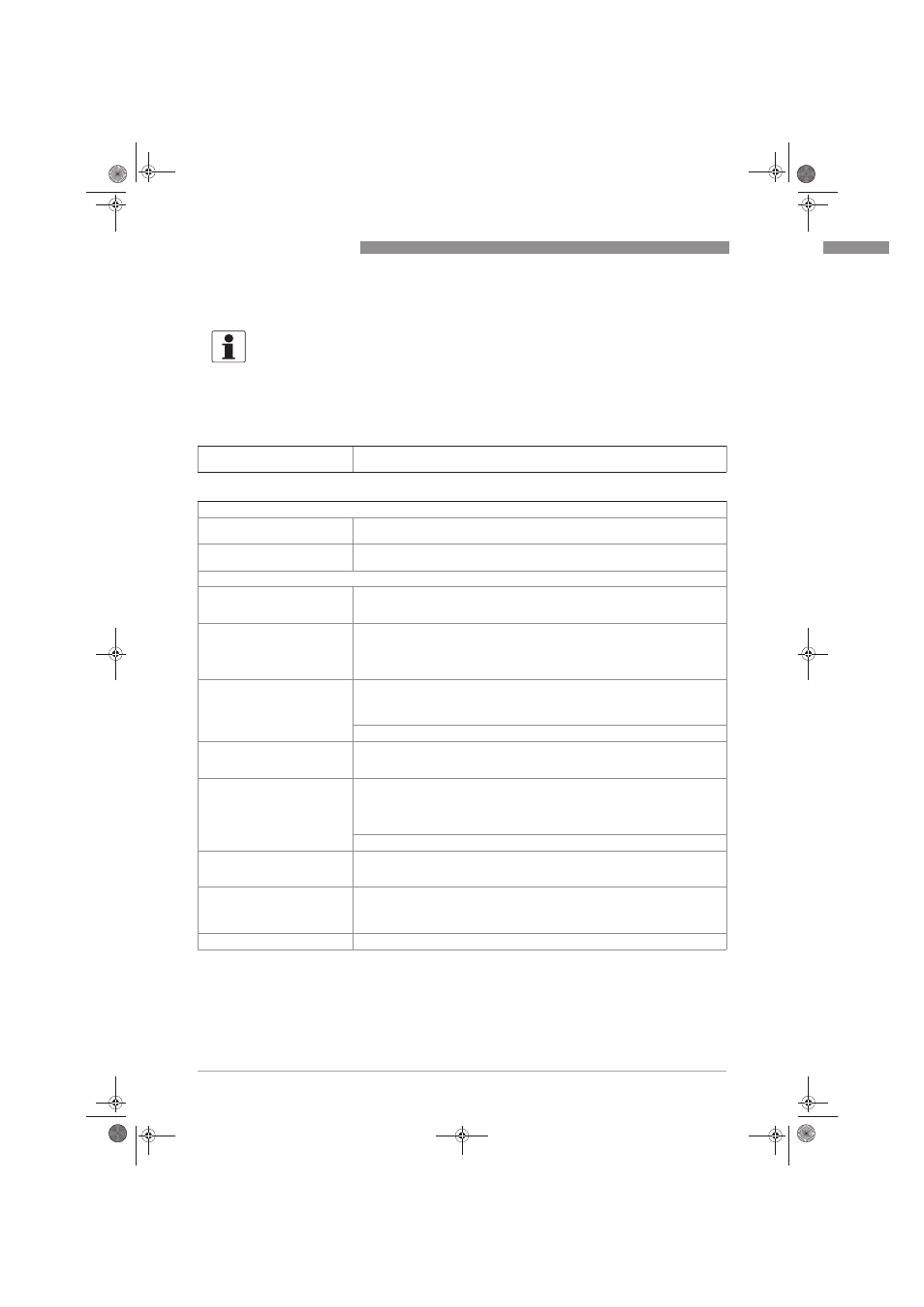

7.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Application range

Temperature, resistance or voltage measurements of solids, liquids and gases in an

industrial environment.

Design

Versions

Versions

Versions

Versions

TT 30 C

In-head transmitter which is optionally available in an intrinsically safe version for

installation in potentially explosive areas of zone 0, 1 and 2.

TT 30 R

Rail-mount transmitter which is optionally available in an intrinsically safe version

for connection to sensors installed in potentially explosive areas of zone 0, 1 and 2.

Special features

Special features

Special features

Special features

Sensor error correction

This function automatically corrects know sensor errors; the precondition is that

you have entered these known sensor errors (e.g. the deviation of a calibrated

sensor from the standard curve).

System error correction

This function corrects the system error (sensor error + transmitter error); the

precondition is that the sensor has been exposed to one (one-point correction) or

two (two-point correction) accurately measured temperatures ("true

temperatures"); after you have entered these true temperature(s), the transmitter

automatically corrects these errors afterwards.

Sensor isolation monitoring /

SmartSense (only for TT 30 C)

This function continously monitors the isolation resistance of thermocouples and 3-

wire connected RTDs as well as the cabling between sensor and transmitter; if the

isolation is too low, the transmitter forces the output to a user-defined level; note

that SmartSense requires an extra lead inside the thermocouple or RTD.

User-definable output: ≤ 3.6 mA, ≥ 21 mA or customized

Customized linearization

A customized linearization with 9 linearization points is available for the

transmitter. It can be used to create almost any type of linearization curve for RTD,

T/C, resistance and mV inputs (the curve must be monotonic increasing).

Sensor break monitoring

This function monitors sensor break and forces the output signal to a user-defined

level if any sensor lead is broken or disconnected, for RTD input it will also detect

sensor short circuit.

The monitoring is furnished with a pulsed excitation current which eliminates the

voltage drop on the lead wires, the sensor break monitoring can be switched off.

User-definable output: ≤ 3.6 mA, ≥ 21 mA or customized

Controlled output for instrument

calibration

You can set the transmitter to automatically provide a recurring output current

regardless of the input signal; the total time for the controlled output is adjustable

up to 30 minutes.

Dampening

This function dampens undesired instabilities on the input signal; the dampening

time is the time required for the output to reach 90% of its final value after a step

change has been applied to the input (in addition to the update time); it is

ca. 2 seconds.

Loop check-up

The transmitter works as an accurate current generator.

.book Page 36 Friday, November 9, 2012 3:50 PM