KROHNE UFM 3030 Service EN User Manual

Page 9

UFM

3030

9

If required the position of the signal converter can be modified by turning the display circuit board

through 90° or 180° to achieve a horizontal position of the display. In addition the signal converter

housing may be turned through 90° opposite the flow sensor.

For an exact description of this procedure, refer to chapter 8.6.

The measuring tube must be completely filled at all times for proper flow measurement, as the

sensors become non-wetted, a loss of signal message will be displayed. There is no damage

when this occurs.

Flow direction. The UFM 3030 is a bi-directional flow meter. Note the indicating arrow for the

positive direction on the flow meter.

It is recommended to protect the signal converter from direct sunlight to prolong the life. Although

no direct damage will occur, installation of a sunshield is advised.

Do not expose the signal converter to excessive vibration. To protect the flow meter from

excessive vibration support the pipeline on either side of the flow meter.

Make sure there is sufficient room next to the pipe flanges to fit the bolts and nuts.

To achieve the specified accuracy of the flow meter, a straight inlet section of 10 × DN (DN =

meter size) and an outlet section of 5 × DN should be applied.

Normally zero setting is not necessary, but if required the zero point can be checked and the

meter can be re-zeroed under stationary flow conditions (see Function 1.01.03 of the converter

menu). To force zero flow, a shut-off valve should be provided upstream and/or downstream of

the flow sensor.

Mixing different fluid products. Install the flow meter upstream of mixing point or at minimum

distance of 30× DN (DN = meter size) downstream of the mixing point, otherwise the flow

measurement may be unstable.

Ambient temperature all flow meters: -40 to +65°C/ -40 to +149°F

Product temperature compact flow meter: -25 to +140°C/ -13 F to +284°F

Product temperature separate flow meter: -25 to +180°C/ -13 to +356°F

Special versions are available for higher process temperatures.

In case of a pipeline running along a wall: please observe a minimum distance between pipe

centreline and the wall of at least 0.5 m (1.6 ft).

2.3

Special installation requirements

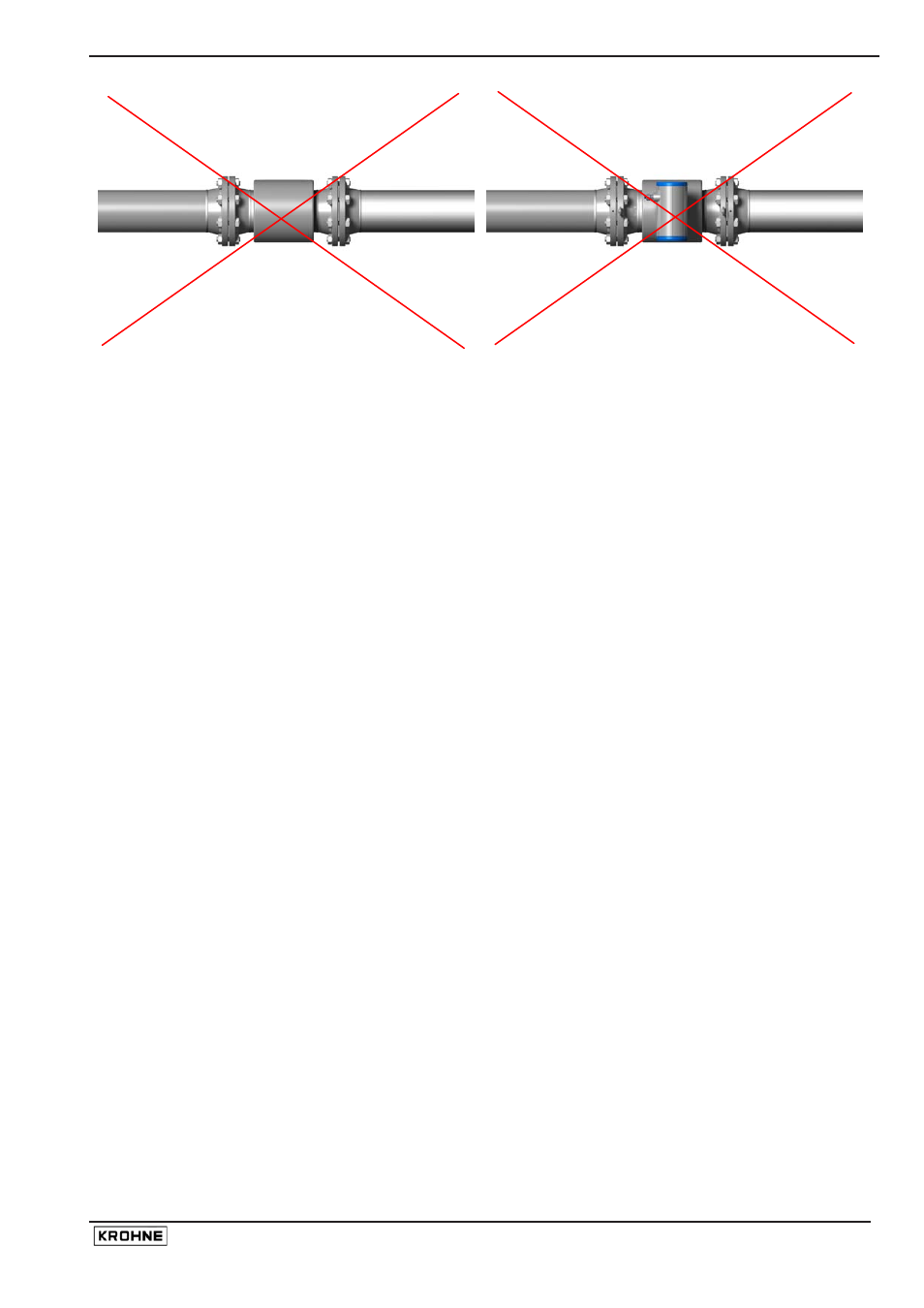

To avoid measuring errors and malfunctioning of the flow meter due to gas or air inclusions or an

empty pipe, please observe the following precautions: