I — description, Table 1. bop 1kw-mg model parameters, Ii — unpacking – KEPCO BOP 1KW-MG Quick Start Guide User Manual

Page 2: Iii — equipment supplied, Table 2. equipment supplied, Description, Unpacking, Equipment supplied, See ta ble 2

2

228-1692 REV 3

112113

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11355 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: [email protected]

I — DESCRIPTION.

The BOP 1KW-MG Series hereafter referred to as

BOP, are true 4-quadrant programmable voltage and

current power supplies, meaning they are capable of

both sourcing and sinking power (see Figure 1).

These bipolar power supplies pass smoothly

through zero without switching to provide true ± volt-

age and ± current. These BOP power supplies use

switch mode technology for low dissipation. A bi-

directional, isolating, a-c input power factor correct-

ing (PFC) circuit recuperates energy sinked from an

active load and sends it back into the line to maintain

low dissipation.

These BOP power supplies are controlled digitally

from a menu-driven front-panel keypad or one of the

standard remote digital interfaces (GPIB or RS 232)

to set voltage and current and the four protection

limits (+voltage, –voltage, +current and –current.) A

front panel rotary adjuster allows real-time adjust-

ment of the output. A large LCD displays the mode

of operation, the settings, and the actual output volt-

age and current. Additionally, these BOP models

can be remotely controlled by an analog ±10V input

for the main channel (voltage or current), and a +1 to

+10V input for the limit channels.

BOP models are suitable for driving inductive loads

such as large magnets or motors, and for exercising

batteries. They are also suitable for characterizing

solar cell arrays, and powering many electrochemi-

cal reactions.

.

II — UNPACKING.

This instrument has been thoroughly inspected and

tested prior to packing and is ready for operation.

After careful unpacking, inspect for shipping damage

before attempting to operate. Perform the “Prelimi-

nary Operational Check.” on page 5. If any indication

of damage is found, file an immediate claim with the

responsible transport service.

III — EQUIPMENT SUPPLIED

.

See Table 2.

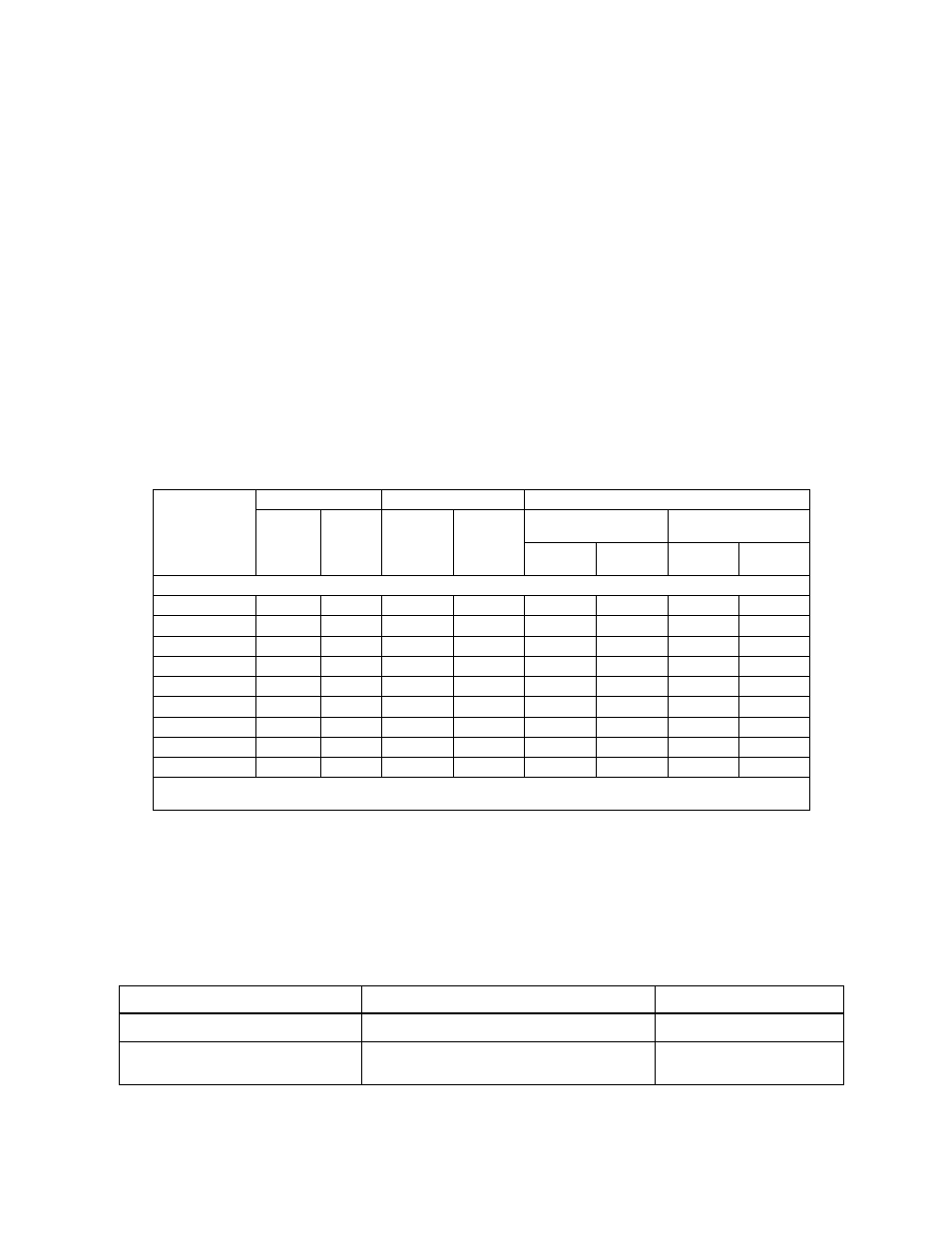

TABLE 1. BOP 1KW-MG MODEL PARAMETERS

Model

d-c Output Range

Closed Loop Gain

Output Impedance

Voltage

(V d-c)

Current

(A d-c)

Voltage

Channel

G

V

(V/V)

Current

Channel

G

I

(A/V)

Voltage Mode

(Series R - L)

Current Mode

(Parallel R - C)

R

d-c

(mOhms)

L

(

µ

H)

R

d-c

(Ohms)

C

(

µ

F)

1000 WATT MODELS

BOP 6-125MG

0 to ±6

0 to ±125

0.6

12.5

0.05

1.5

24

1150

BOP 10-100MG

0 to ±10

0 to ±100

1.0

10.0

0.1

2.0

50

1100

BOP 10-75MG

0 to ±10

0 to ±75

1.0

7.5

0.13

2.0

67

976

BOP 20-50MG

0 to ±20

0 to ±50

2.0

5.0

0.40

8.3

200

371

BOP 25-40MG

0 to ±25

0 to ±40

2.5

4.0

0.63

15.8

313

165

BOP 36-28MG

0 to ±36

0 to ±28

3.6

2.8

1.30

25

640

103

BOP 50-20MG

0 to ±50

0 to ±20

5.0

2.0

2.50

50

1250

55

BOP 72-14MG

0 to ±72

0 to ±14

7.2

1.4

5.14

104

2570

33

BOP 100-10MG

0 to ±100

0 to ±10

10.0

1.0

10.0

163

5000

16

NOTE: When connecting active loads, the steady-state voltage of the active load must not exceed the maximum voltage rating of the

BOP. Otherwise the overvoltage protection will shut down the power supply.

TABLE 2. EQUIPMENT SUPPLIED

ITEM

FUNCTION

PART NUMBER

Source Power Entry mating connector

Mates with source power entry connector

142-0381 (Kepco) (IEC 320)

PAR/SER CONTROL - IN

mating connector

Mates with PAR/SER CONTROL - IN port to allow

access to pins required for calibration

142-0488 (Kepco)