5 interference data, 6 explosion proof enclosures, Interference data – Detcon 1000 User Manual

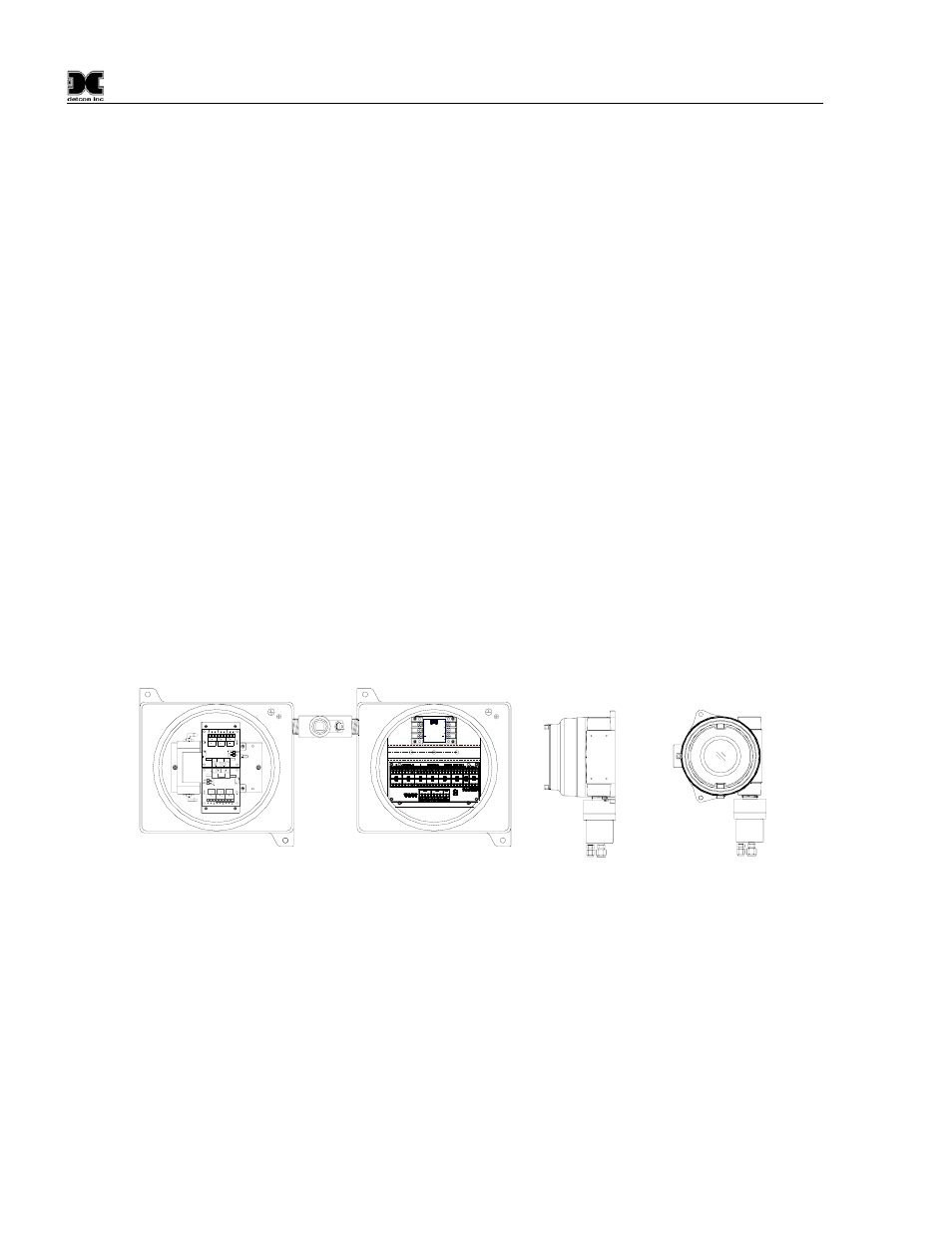

Page 8: Explosion proof enclosures, Figure 6 explosion proof enclosures

Mdl 1000 H2S E-Chem / Inst. Air

Model 1000 H2S E-Chem w Instrument Air Rev. 1.1

Page 4 of 28

1.5 Interference Data

DM-624 series electrochemical H

2

S sensors are subject to interference from other gases. This interaction is

shown in the following table as the relation between the amount of the interfering gas applied to the sensor,

and the corresponding reading that will occur (in ppm).

Gas

Interference

Carbon monoxide

300ppm

≤1.5ppm

Chlorine

1ppm = -0.2ppm

Ethyl mercaptan

3ppm = 1ppm

Ethylene

100ppm = 0

Hydrogen

1% = < 5ppm

Hydrogen chloride

5ppm = 0

Hydrogen cyanide

10ppm = 0

Nitric oxide

35ppm < 2ppm

Nitrogen dioxide

5ppm = -0.5ppm

Sulfur dioxide

5ppm < 1ppm

Methyl mercaptan

2ppm = 1ppm

1.6 Explosion Proof Enclosures

The sensor is packaged in a cast metal explosion proof enclosure. The enclosure is fitted with a threaded cover

that has a glass lens window. Magnetic program switches located behind the transmitter module faceplate are

activated through the lens window via a hand-held magnetic programming tool allowing non-intrusive

operator interface with the sensor. All calibration and alarm level adjustments can be accomplished without

removing the cover or declassifying the area. Electrical classification is Class I; Div. 1; Groups C, D.

+

+

24VDC

OUT

2.1A

18-36

VDC

IN

Flow Fault (optional)

Pump/Scrubber

Power Supply/

Terminal PCB

Sensor (side view)

Sensor

Right

Left

Figure 6 Explosion proof enclosures

A 24VDC power supply and termination PCB for the power, relay contacts, 4-20mA output, and/or RS485

signal, are located in the upper right explosion proof enclosure. The pump and optional low flow fault

assemblies are located in the upper left explosion proof enclosure. Declassify the work area before removing

covers.