2 electrochemical sensor, 3 microprocessor control circuit, Electrochemical sensor – Detcon 1000 User Manual

Page 6: Microprocessor control circuit, Figure 2 construction of electrochemical sensor

Mdl 1000 H2S E-Chem / Inst. Air

Model 1000 H2S E-Chem w Instrument Air Rev. 1.1

Page 2 of 28

Detcon MicroSafe™ Model DM-624, toxic sensors are non-intrusive “Smart” sensors designed to detect and

monitor for H

2

S gas in the ppm range. A primary feature of the sensor is its method of automatic calibration,

which guides the user through each step via instructions displayed on the backlit LCD. The sensor features

field adjustable, fully programmable alarms and provides relays for two alarms plus fault as standard. The

sensor comes with two different outputs: analog 4-20mA, and serial RS-485. These outputs allow for greater

flexibility in system integration and installation. The microprocessor-supervised electronics are packaged as a

plug-in module that mates to a standard connector board. Both are housed in an explosion proof condulet that

includes a glass lens window that allows for the display of sensor readings as well as access to the sensor’s

menu driven features via a hand-held programming magnet.

1.2 Electrochemical Sensor

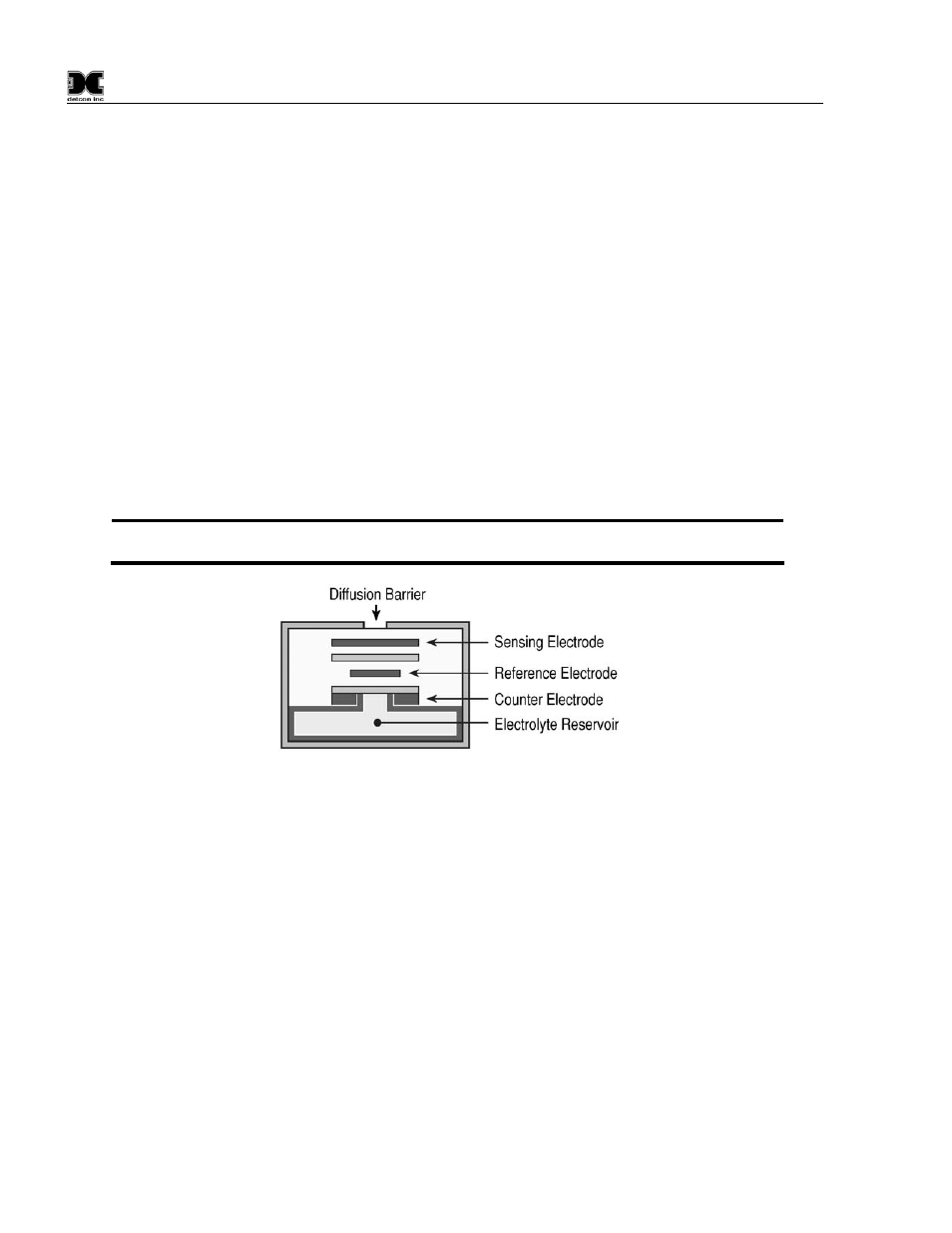

The sensor is an electrochemical cell. Each cell consists of three electrodes embedded in an electrolyte

solution all housed beneath a diffusion membrane. Sensitivity to specific target gases is achieved by varying

composition of any combination of the sensor components. Good specificity is achieved in each sensor type.

The cell is diffusion limited via small capillary barriers resulting in long service life of up to 3 or more years

depending on the application.

NOTE: This particular sensor cell is unique in that it has no cross-sensitivity to alcohol vapors

and thus is a good choice for measuring H

2

S in natural gas pipelines.

Figure 2 Construction of Electrochemical Sensor

DM-624 Electrochemical Sensor Principle of Operation

Method of detection is by an electrochemical reaction at the surface of an electrode called the sensing

electrode. Air and gas diffuse through the stainless steel filter and the capillary diffusion barrier. The

controlling circuit maintains a small external operating voltage between the sensing and counter electrodes of

the proper bias and magnitude so that no current flows to or from the reference electrode while its potential is

maintained at the correct fixed voltage — usually ground. The electrochemical reaction creates a change in

current flow from the counter electrode to the sensing electrode. This change in current is proportional to the

gas concentration and is reversible. The quick response of the sensor results in continuous monitoring of

sample gas conditions.

1.3 Microprocessor Control Circuit

The control circuit is microprocessor based, and is packaged as a plug-in field replaceable module, facilitating

easy replacement and minimum down time. Circuit functions include a basic sensor pre-amplifier, on-board

power supplies, microprocessor, back lit alpha numeric display, alarm status LED indicators, magnetic

programming switches, an RS-485 communication port, and a linear 4-20mA DC output.