Calibration and maintenance, 1 zero calibration, 2 span calibration – Detcon 1000 User Manual

Page 19: Zero calibration, Span calibration

Mdl 1000 H2S E-Chem / Inst. Air

Model 1000 H2S E-Chem w Instrument Air

Rev. 1.1

Page 15 of 28

6. Calibration and Maintenance

The Model 1000 Series H

2

S Process Analyzer is calibrated prior to shipment. Only minimal adjustment

should be required at time of commissioning. However, it is highly recommended that a zero and span

calibration be performed twice in the first week of operation to assure optimum system performance. After

that, a recalibration interval of every month is recommended.

Maintenance

When the Acetic Acid Bubbler option is used, the 5% acetic acid solution (or white vinegar) should be kept

near the Max fill mark on the bottle. The level should be checked monthly and the entire solution contents

should be changed every 6 months.

Material Requirements

9

Detcon Part Number 327-000000-000 MicroSafe™ Programming Magnet.

9 Detcon Part Number 942-001123-000 Zero Air cal gas. (Ambient air can be used, if it can be verified that

no target gas is present).

9 Span gas cylinder containing H

2

S gas in background N2 (nitrogen) as per the following range table. If

available, span gas cylinders in background Methane (natural gas) or air can also be used.

6.1.1 Zero Calibration

Zero Calibration should be performed quarterly in the field. The AutoZero function is used to zero the sensor.

The dilution airflow (with sample turned off) can be used to zero calibrate the sensor. Alternately, a zero air or

N

2

cylinder connected to the calibration port can be used.

1) Turn the sample flow mass control off, leaving only the airflow to provide the zero gas. Allow the unit 5

minutes to stabilize.

2) Enter the calibration menu by holding the programming magnet stationary over “PGM 1” (see above) for 3

seconds until the display reads “1-ZERO 2-SPAN”, and remove the magnet. Note that the “CAL” LED

comes on.

3) Enter the zero menu by holding the magnet stationary over “PGM 1” for 3 seconds until the display reads:

“AUTOZERO”, and remove the magnet. The sensor will enter the auto zero mode. When complete the

sensor will display “ZERO COMPLETE” for 5 seconds and then return to the normal operation menu,

“0.00PPM H2S”.

4) Re-open the sample flow mass control and re-establish the target sample flow rate per the arrow indicator

on the H

2

S sample Rotameter.

6.1.2 Span Calibration

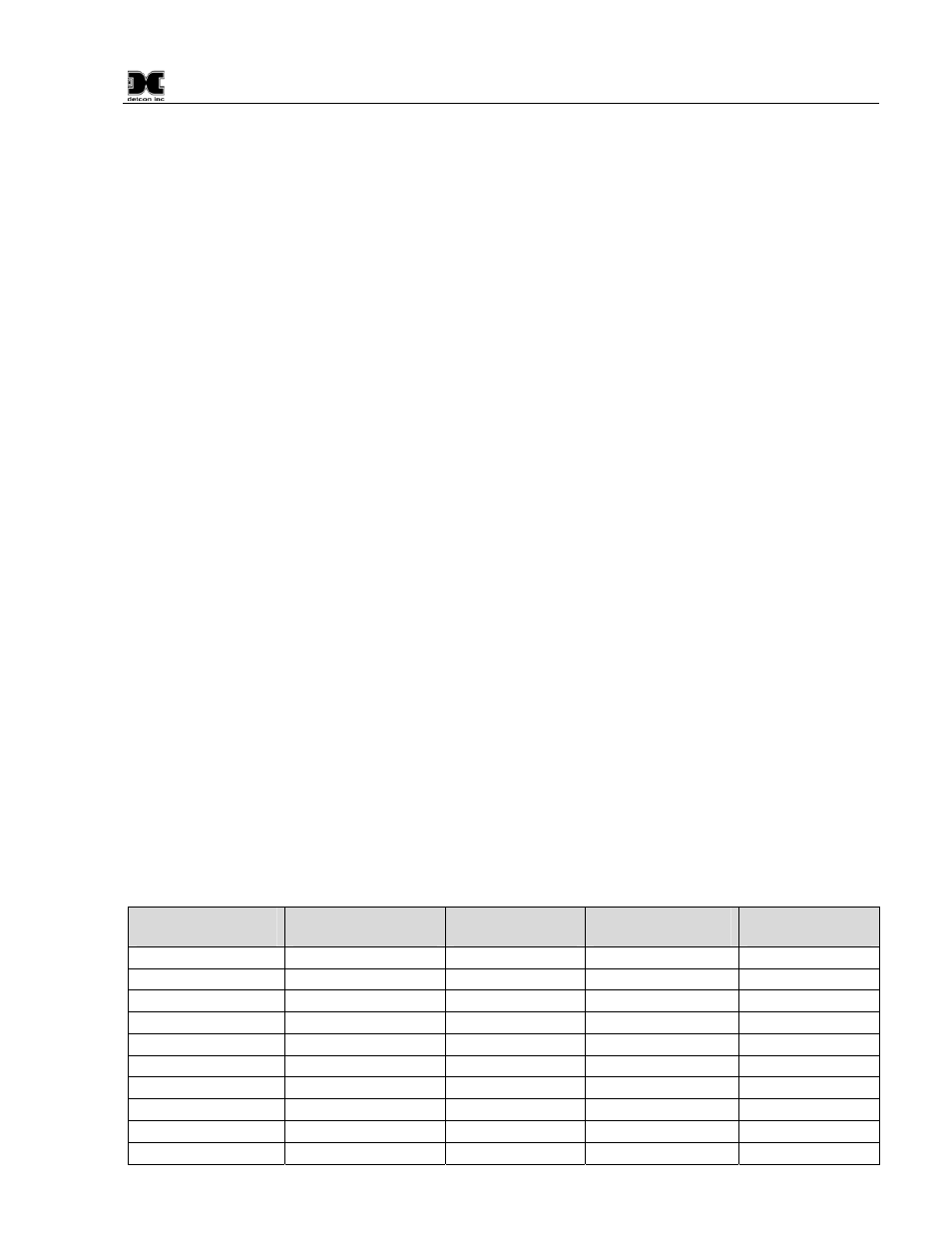

Table 3 Sample Flow Rate

DM-624 Range

(ppm)

Sample Flow

(cc/min)

Air Flow

(cc/min)

Span Gas Flow

(cc/min)

H

2

S Cal Gas

(ppm)

0-10

200 Labeled “S

→”

500

250 Labeled “C

→”

10

0-20

200 Labeled “S

→”

500

250 Labeled “C

→”

10

0-25

200 Labeled “S

→”

500

250 Labeled “C

→”

10

0-50

200 Labeled “S

→”

500

250 Labeled “C

→”

10 or 25

0-100

200 Labeled “S

→”

500

250 Labeled “C

→”

25 or 50

0-150

200 Labeled “S

→”

500

250 Labeled “C

→”

25 or 50

0-500

80 Labeled “S

→”

1000

100 Labeled “C

→”

100

0-5000

200 Labeled “S

→”

800

250 Labeled “C

→”

1000 or 2500

0-10,000

80 Labeled “S

→”

800

100 Labeled “C

→”

2,500 or 5,000

0-2%

200 Labeled “S

→”

750

250 Labeled “C

→”

5,000