3 electrical connections, Electrical connections, Figure 8 port identification – Detcon 1000 User Manual

Page 11

Mdl 1000 H2S E-Chem / Inst. Air

Model 1000 H2S E-Chem w Instrument Air

Rev. 1.1

Page 7 of 28

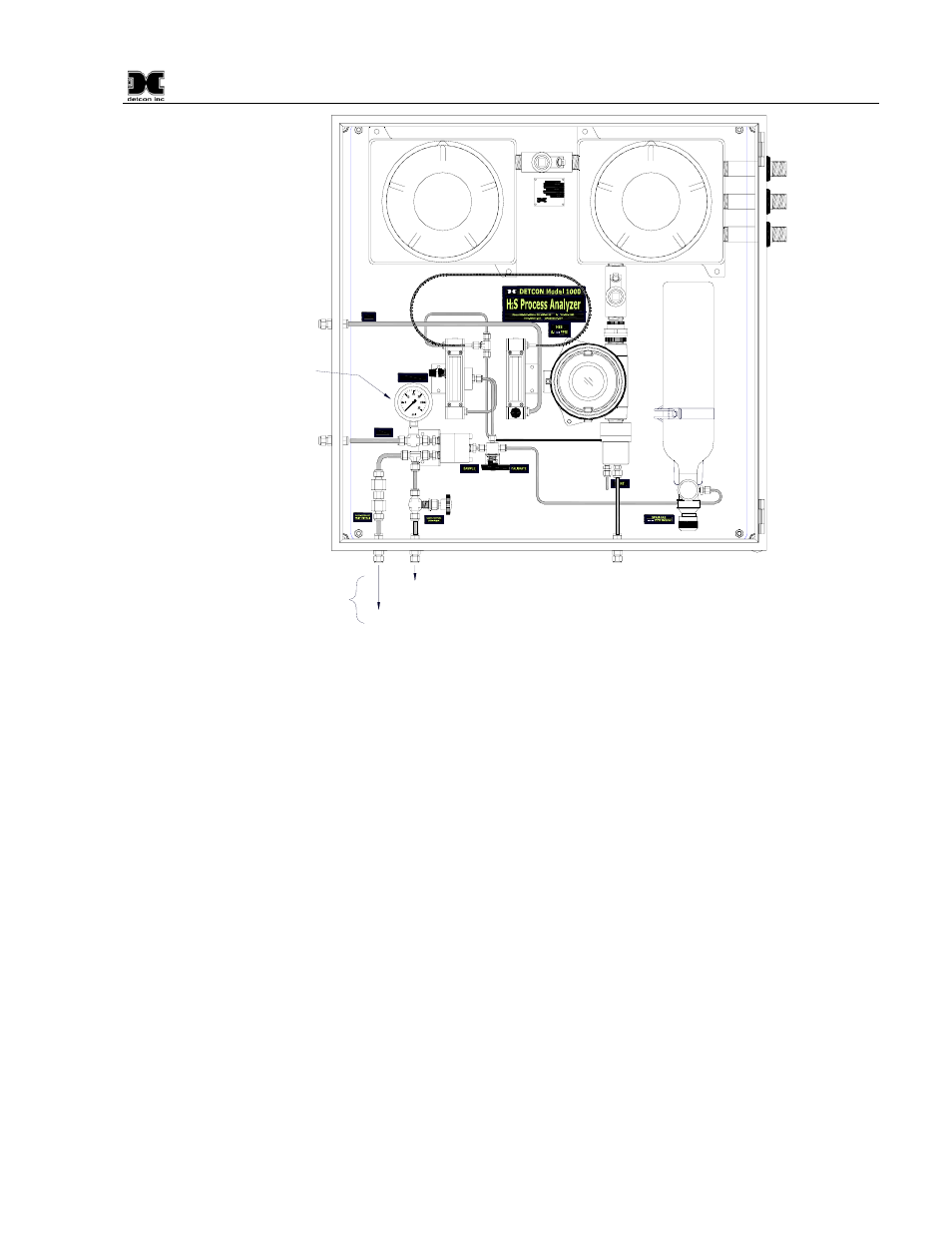

Instrument Air Inlet Port

Sample Inlet Port

Pressure Gauge

Sample Bypass and Liquid

Rejection Exhaust Vent.

Over Pressure Relief Vent

NOTE:

These may be

combined into a

single vent

Sample Calibrate

H

2

S Vent

Cal Gas

SAMPLE

FLOW

AIR

FLOW

INLET

SAMPLE

10 PSIG (CONSTANT)

SAMPLE PRESSURE

INLET

AIR

MODEL NO.

SERIAL NO.

INPUT VOLTAGE

FREQUENCY

CURRENT LOAD

AREA CLASSIFICATION

detcon inc.

3200 A-1 Research Forest Dr.

The Woodlands, TX 77381

www.detcon.com

PART NO.

Figure 8 Port Identification

2. Supply Instrument Air to the “Air Inlet” port (Figure 8). The instrument air should be regulated to

10±1psig.

3. Whenever possible, the Sample Bypass flow control valve of the Genie membrane filter should be used to

minimize the sample lag time between the sample tap and the analyzer location. It can also be used as a

means to exhaust condensed liquids in the sample line away from the Genie filter and prevent a “loss of

flow” condition. Set a flow of 100-200cc/min. and vent to a safe area using ¼” O.D. tubing.

4. Connect to the Over-pressure Relief valve and vent to a safe area. The pressure relief valve is set at

Detcon to open at 15-20psig. For convenience sake, the sample bypass and over-pressure relief can be

vented together.

5. Install a length of ¼" OD stainless steel tubing from the vent port to an area deemed safe for venting as

shown in Figure 8. Venting pressure should be in the range of 0±1psig and ambient pressure is highly

preferred.

3.3 Electrical Connections