Detcon PI-600 User Manual

Page 25

3.8.4 Calibration Frequency

In most applications, monthly to quarterly calibration intervals will assure reliable detection. However, industrial envi-

ronments differ. Upon initial installation and commissioning, close frequency tests should be performed, weekly to

monthly. Test results should be recorded and reviewed to determine a suitable calibration interval.

3.8.5 PID Plug-In Sensor Maintenance

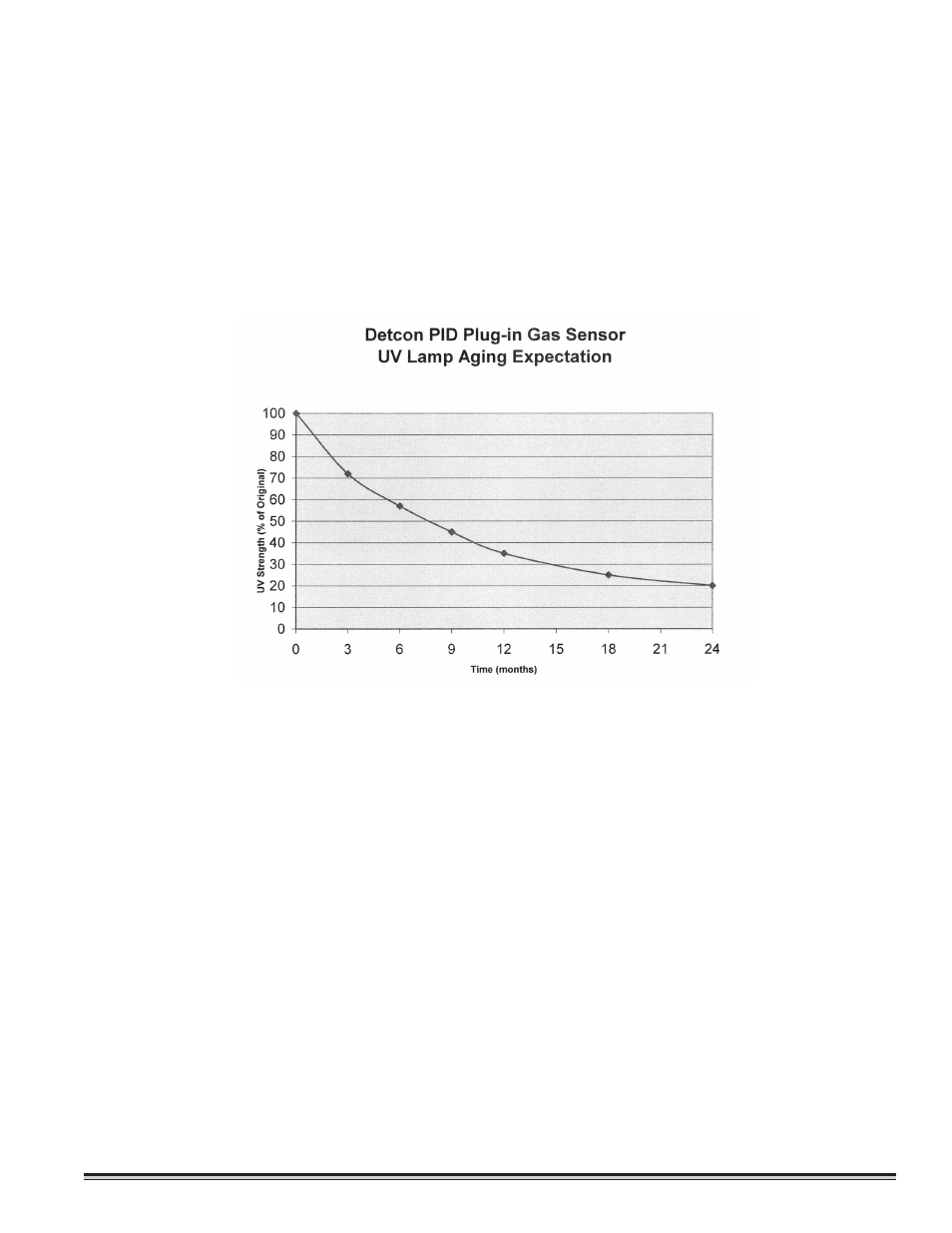

The plug-in PID Sensor will need to be properly maintained to achieve proper long-term performance. All PID sensors

use a UV lamp that has a f inite lifetime. The Detcon PID UV lamp source is expected to last a least 1 year. However,

from the time of installation a gradual loss in UV lamp strength is expected. (See Figure 8) As the UV lamp strength

decreases the sensor signal will decrease accordingly. This dictates that periodic span calibrations are required to main-

tain calibration accuracy.

To determine the present signal strength of the PID sensor, execute a valid span calibration and view the Sensor Life

from the ‘View Program Status’ menu. Any Sensor Life value less than 30% should result in the user’s choice of replac-

ing the plug-in sensor, cleaning the UV Lamp, or replacing the UV Lamp.

If the PID sensor seems to be losing signal strength at a rate faster than Figure 8 estimates, the sensor is most likely

experiencing contamination f ilm build-up on the UV optical f ilter. This will happen when exposed to certain gases or

ambient contaminations that collect on the surafce of the UV f ilter. The result is a decrease in the amount of emitted

UV from the lamp source. This is known to happen with gases that can be polymerized by UV light (such as heavy

complex VOC’s), airborne oil vapors, and very f ine dust. As UV Filter contamination occurs, the sensor’s signal

strength falls off in addition to the expected loss rate shown in Figure 8. This phenomenon can be reversed by disas-

sembling the sensor and carefully cleaning the UV lamp f ilter using a specialized cloth.

It is also possible under certain ambient contamination conditions that the sensor’s Detector Cell can have a partially

conductive f ilm that forms across the contact grids. This condition causes the zero background signal to gradually

increase to the point where it becomes unacceptable for the range of signal input to the transmiter electronics. When

this occurs the detector cell should be replaced. This can be checked by examining the amount of raw signal that is

produced during exposure to zero gas. Refer to the ‘View Program Status’ menu and record the Raw Signal report after

5 minutes of zero gas exposure. A value that exceds 2.65V would be evidence of this problem.

3.8.5.1 General recomendations for Sensor Maintenance

1) For normal environmental exposure and signal decay, replace the plug-in sensor every 9-12 months (especially if

there are no skilled technicians to handle proper UV lamp replacement).

PI-600 Toxic Gas Sensors PG.25

Figure 8