Pressure ranges ordering information, Dimensional data, 4000 e – AST AST5100 Datasheet User Manual

Page 2

TM

www.astsensors.com

© 2014 American Sensor Technologies Inc. AST5100 03/13/2014.

All specifications subject to change without notice.

4

000

E

Pressure Unit

H= Inches H

2

O

P= PSI

Pressure Ranges

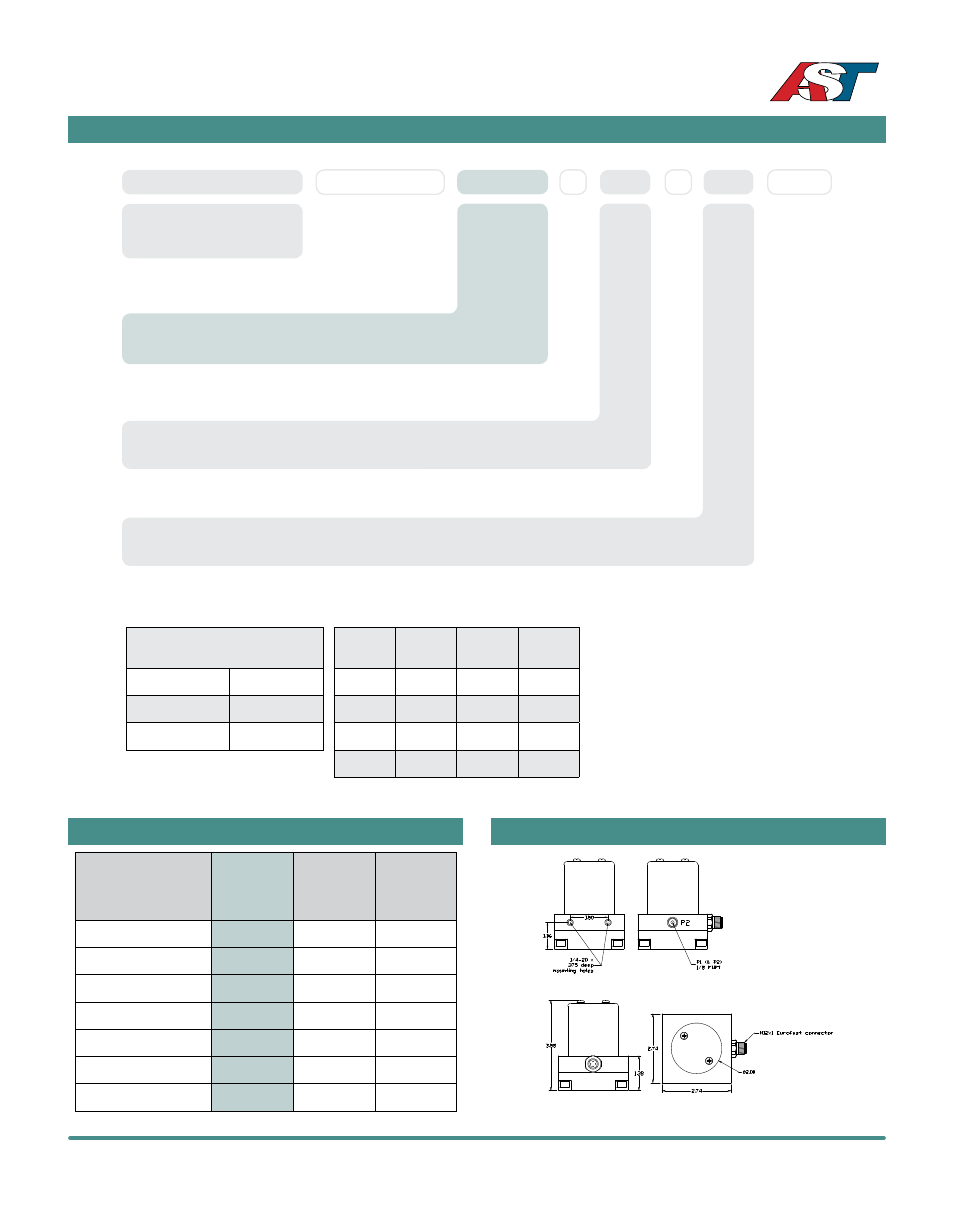

Ordering Information

Options

000= No Options

Wetted Material

5= Nickel Alloy 52, Ni-Span C, Viton, 304 Stainless Steel, Aluminum 6061, RoHSSolder, Loctite 680 (meets NSF61)

Electrical (for wiring information visit: http://www.astsensors.com/wiring.php)

Y= M12x1

Outputs

2= 0-5V 3-wire

4= 4-20mA (2 wire loop powered)

Pressure Range

See Chart

Process Connection

J= 1/8” NPT Female

Series Type

5

Y

H

00050

J

AST5100

Mating PUR 22 AWG Cable Assembly

Part Number

Cable Length

A10089

4 feet (1 m)

A10090

10 feet (3 m)

Pins

Conductor

Colors

0-5V

3-wire

4-20mA

Pin 1

Brown

+V

+V

Pin 2

White

N/C

N/C

Pin 3

Blue

-V

-V

Pin 4

Black

V Out

N/C

Differential

Pressure

Pressure

Code

Proof

Pressure

(P1>P2)

Proof

Pressure

(P2>P1)

0-5 inch H

2

O (12.5 mbar)

00005H

5 PSI

3 PSI

0-10 inch H

2

O (25 mbar)

00010H

5 PSI

3 PSI

0-20 inch H

2

O (50 mbar)

00020H

8 PSI

5 PSI

0-50 inch H

2

O (125.5 mbar)

00050H

15 PSI

10 PSI

0-100 inch H

2

O (249 mbar)

00100H

35 PSI

25 PSI

0-200 inch H

2

O (498 mbar)

00200H

35 PSI

25 PSI

0-15 PSID (1034 mbar)

00015P

75 PSI

50 PSI

The over-pressure specification is the maximum pressure the AST5100 can

see without damage. Any pressure applied over the listed numbers will likely

damage the sensor and will, at minimum, cause a permanent zero shift.

Over-pressure between 2X span and the numbers listed applied to port P1

will likely cause no permanent harm. Over-pressure of between 2X span and

the numbers listed applied to port P2 may cause a temporary zero shift. To

recover from a zero shift caused by negative over-pressure to P2 within the

listed limits, apply a positive over-pressure P1 to just under the listed limit

for a duration of 5 minutes. Remove the over-pressure and check the zero

with no pressure applied. If the zero has not recovered, repeat the positive

over-pressure and recheck zero. If it has not recovered after the second try,

the zero has been permanently shifted. Contact the factory.

Dimensional Data