4 parameter descriptions / settings, 1 emissivity ε, 1 emissivity table – LumaSense Technologies IS 310 User Manual

Page 13: 1 emissivity

IS 310 / IGA 310 Manual

Parameter descriptions / settings 13

4 Parameter descriptions / Settings

4.1 Emissivity

For a correct measurement, it is necessary to adjust the emissivity . This emissivity is the

relationship between the emission of a real object and the emission of a black body radiation

source (this is an object which absorbs all incoming rays and has an emissivity of 100%) at the

same temperature. Different materials have different emissivities ranging between 0% and

100% (settings at the pyrometer between 0.2 ... 1, equivalent to 20 … 100%). Additionally, the

emissivity is dependent on the surface condition of the material, the spectral range of the

pyrometer, and the measuring temperature. The emissivity setting of the pyrometer has to be

adjusted accordingly. Typical emissivity values of various common materials for the two spectral

ranges of the instruments are listed in the emissivity table below. The tolerance of the emissivity

values for each material is mainly dependent on the surface conditions. Rougher surfaces have

higher emissivities.

Note: The pyrometer is set ex works to an emissivity of 100%.

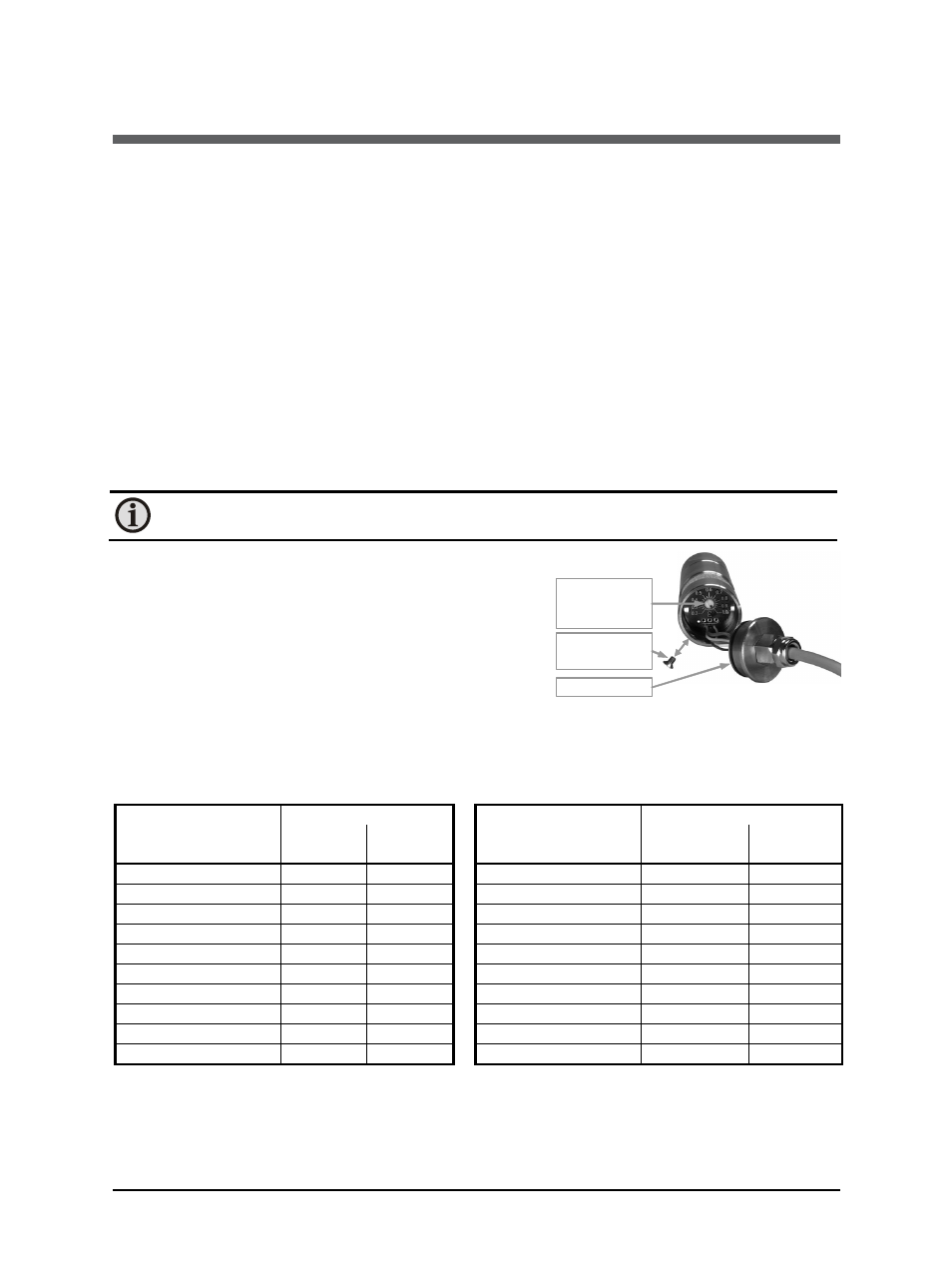

To adjust the emissivity factor to your own purpose, you

have to remove the rear cover by unscrew the locking

screw. Be sure to remove the cover carefully. In the tube

there is a scale that can be turned with a small

screwdriver. Adjust the emissivity factor to your desire.

After that, push the cable carefully back in the tube, put

the cover on the tube and tighten the locking screw for

the cover.

The following table may give brief information of the correct setting of the emissivity. For exact

measurement we recommend a comparison measurement with a contact thermometer (e.g.

TASTOTHERM MP 2000 with a suited probe).

4.1.1 Emissivity table

Measuring object

Emissivity [%]

Measuring object

Emissivity [%]

IS 310

(at 0.9 µm)

IGA 310

(at 1.6 µm)

IS 310

(at 0.9 µm)

IGA 310

(at 1.6 µm)

„Blackbody furnace“

1

1

Zinc

0.58

0.45...0.55

Steel heavily scaled

0.93

0.85...0.9

Nickel

0.22

0.15...0.2

Steel rolling skin

0.88

0.8...0.88

Gold, Silver, bright

0.02

0.02

Steel, molten

0.3

0.2...0.25

Porcelain glazed

0.6

0.6

Slag

0.85

0.8...0.85

Porcelain rough

0.8...0.9

0.8...0.9

Aluminum, bright

0.15

0.1

Graphite

0.8...0.92

0.8...0.9

Chromium, bright

0.28...0.32 0.25...0.3

Chamotte

0.45...0.6

0.45...0.6

Brass oxidized

0.65...0.75

0.6...0.7

Earthenware, glazed

0.86...0.9

0.8...0.9

Bronze, blank

0.03

0.03

Brick

0.85...0.9

0.8...0.9

Copper, oxidized

0.88

0.7...0.85

Soot

0.95

0.95

Potentiometer

for emissivity

adjustment

Locking screw

for rear cover

Rear cover