6 transmittance, 7 emiautofind, 8 response time/exposure time (t90) – LumaSense Technologies IS 320 User Manual

Page 16: 8 response time/exposure time (t

IS 320 • IGA 320 Manual

General 16

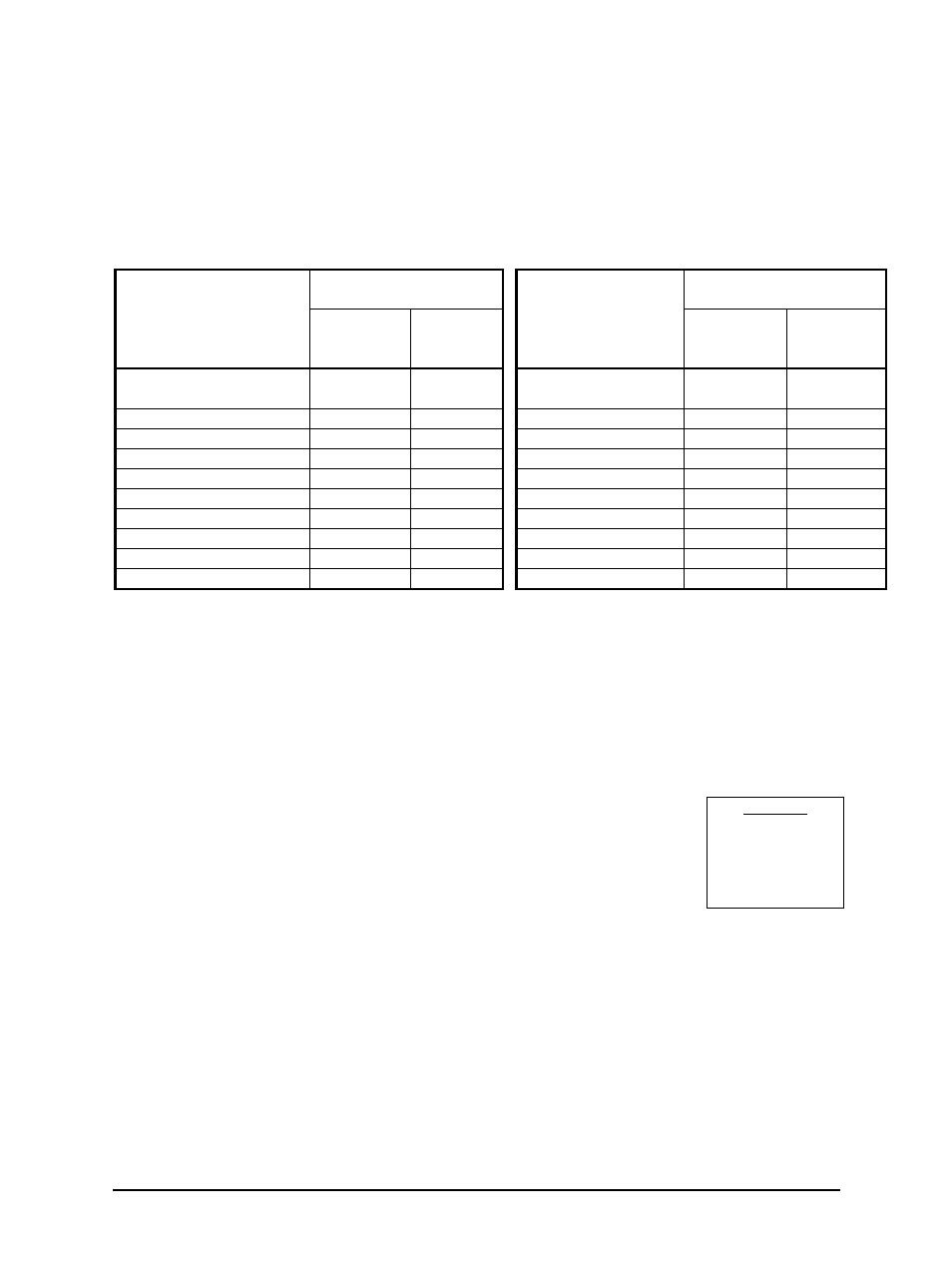

same temperature. Different materials have different emissivities, ranging from 0% to 100%.

The emissivity of an object is dependent on the surface condition of the material, the spectral

range of the pyrometer and the measuring temperature. The emissivity setting of the pyrometer

has to be adjusted accordingly (by entering a number between 10 and 100%). Typical emissivity

values of various common materials for the two spectral ranges of the instruments are listed

below. The tolerance of the emissivity values for each material is mainly dependent on the

surface conditions. Rough surfaces have higher emissivities.

Measuring

object

Emissivity [%]

Measuring

object

Emissivity [%]

IS 320

(0.8...

1.1 µm)

IGA 320

(1.45...

1.8 µm)

IS 320

(0.8...

1.1 µm)

IGA 320

(1.45...

1.8 µm)

“Black body

furnace“

100

100

Zinc

58

45

to

55

Steel heavily scaled

93

85 to 90

Nickel

22

15 to 20

Steel rolling skin

88

80 t 88

Gold, Silver, bright

2

2

Steel, molten

30

20 to 25

Porcelain glazed

60

60

Slag

85

80 to 85

Porcelain rough

80 to 90

80 to 90

Aluminum, bright

15

10

Graphite

80 to 92

80 to 90

Chromium, bright

28 to 32

25 to 30

Chamotte

45 to 60

45 to 60

Brass oxidized (tarnished)

65 to 75

60 to 70

Earthenware, glazed

86 to 90

80 to 90

Bronze, bright

3

3

Brick

85 to 90

80 to 90

Copper, oxidized

88

70 to 85

Soot

95

95

4.6 Transmittance

Due to the transmittance, measurements through windows slightly attenuate the measuring

signal. To ensure accurate measurements, the software can compensate for the transmission of

the window. Alternatively the emissivity can be adapted.

4.7 EmiAutoFind

If the true temperature of the measured object is known, you can calculate the emissivity of the

measured object using the “Emi: AutoFind” function (software InfraWin).

4.8 Response Time/Exposure Time (t

90

)

Exposure time is the amount of time that the measured temperature has to

be present after an abrupt change before the output value of the pyrometer

is updated. The time it takes to reach 90% of the recorded temperature

difference is the response time. In the “min” position, the device operates

using its time constant.

The dynamic exposure time adjustment prolongs the exposure time at the lower range limit,

also t

90

is set to a lower value.

If the maximum value storage is selected, the measuring object has a low emissivity and the

measuring temperature is at the beginning of the range, a higher exposure time must be chosen

to prevent measurement errors. Longer exposure times can be used for the measurement of

objects which have rapidly fluctuating temperatures to achieve constant temperature reading.

Settings:

min

0.01 s

0.05 s

...

10.00 s