Warning, Maintenance, Wiring diagrams, schematics, etc – Hired-Hand Farm Hand Series: Stage Master User Manual

Page 19

Part No. 4801-0151 Rev 4-06

Farm Hand Stage Master

19 of 40

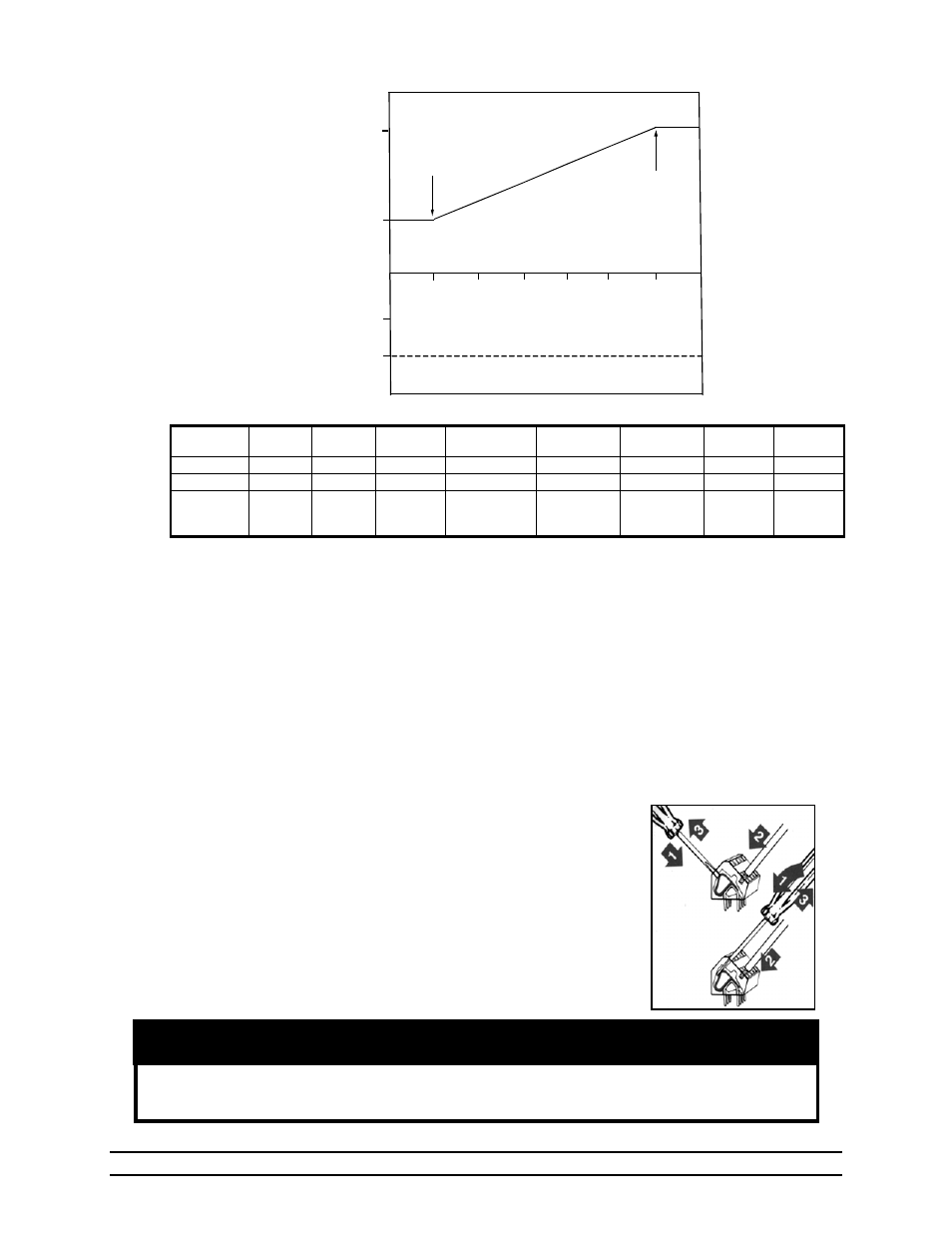

Brief Description of Progressive Cool Timer Option

As you can see from graph 3, as the temperature increases above the Minimum OnPoint,

(OFF=75ºF) the Runtime % progressively increases until it reaches 100% at its Maximum OnPoint

(ON = 80ºF). When using this option, it is not necessary to set P10 or P11 for the stage. These

parameters only apply to variable speed operation.

10. Maintenance

Check the calibration of your sensors at least once per quarter. To do this, you will need to have two

persons: one at the sensor with a trusted thermometer, and one at the controller to set the sensor to the

proper setting.

11. Wiring Diagrams, Schematics, etc.

All wiring connections for stages, curtain machines, variable speed

fans, and curtain sensors inside the controller are made without

terminals on the end of the wire. To make the connection, strip about

¼” of the insulation off the wire, and follow the diagram below.

1. Insert a small screwdriver into either the hole shown in the

diagram.

2. Insert the stripped end of the wire into the hole shown in the

diagram.

3. Remove the screwdriver, and tug slightly on the wire to check

that it is snug.

Warning!

Do not connect more than 12 amps of load to any one stage. The Variable Speed

Circuit will carry up to 12 amps.

100

Percent Of R

unti

m

e

Percent Of

Full S

pee

d

50

50

100

76

78

80

77

75

79

Graph 3 Progressive Cool Timer Option

Maximum

OnPoint

TEMPERATURE (F)

Minimum

OnPoint

Table 3 Progressive Cool Timer Option

Setting Stage

Sensor

Stage

Mode

Stage

Timer

Minimum

OnPoint

Maximum

OnPoint

Minimum

Runtime %

Motor

Curve

Var/

Timer %

Parameter

P1 P2 P3 OFF

ON

P10

P11 N/A

Value

10 02 02 75

80

N/A N/A 50

Option

Sensor 1

Cool Stir

Timer ON

Stage begins

varying

Runtime

Stage runs

continuously

N/A

N/A

Refer to

Section

5.1